How Phenolic Pipe Insulation Section Controls Condensation and Protects Pipelines

2025-11-02 11:44:26

In modern construction and industrial systems, one critical goal is to minimize energy waste while preventing condensation on cold surfaces. A proven solution for this challenge is the Phenolic Pipe Insulation Section — a high-efficiency insulating material that shields pipelines from temperature fluctuation and moisture.

Engineered from phenolic foam and supplied globally by China insulation manufacturers, this material has become a trusted choice in HVAC, chemical, and refrigeration sectors. Its closed-cell structure and low thermal conductivity deliver unmatched condensation control with long service life, making it ideal for large-scale use and bulk supply directly from factories.

Why Condensation Happens in Pipelines

Condensation forms when a pipe’s outer surface becomes cooler than the surrounding air’s dew point. Moisture in the air then condenses on the pipe wall, forming water droplets. Over time, this seemingly small issue can cause corrosion, microbial growth, system inefficiency, and maintenance costs.

Unprotected chilled water pipes and air-conditioning lines are especially vulnerable. Even a slight temperature difference can lead to water build-up, dripping, and insulation failure. The only way to eliminate this risk is by ensuring proper thermal insulation that maintains surface temperatures above the dew point — something Phenolic Pipe Insulation Sections achieve exceptionally well.

What Makes Phenolic Pipe Insulation Section Unique

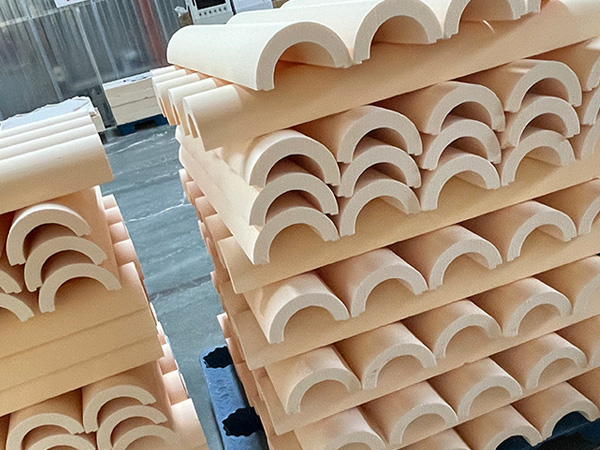

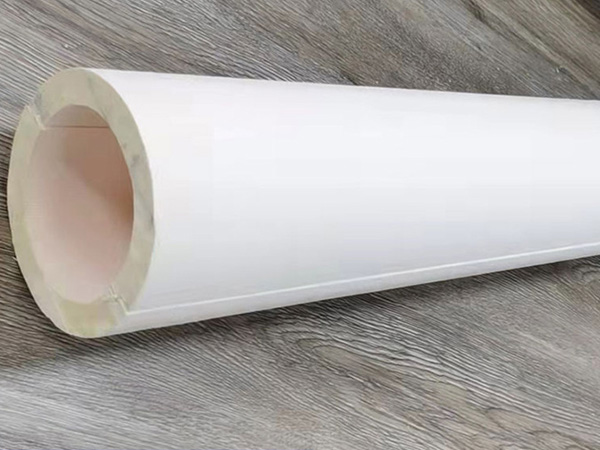

A Phenolic Pipe Insulation Section is made from rigid phenolic foam — a material created through the controlled reaction of phenol and formaldehyde with a foaming agent. The result is a dense, fine-cell structure that offers excellent heat resistance and minimal moisture absorption.

The sections are typically pre-molded to fit standard pipe diameters and can be laminated with aluminum foil or glass fiber for added vapor protection. The combination of structural rigidity and moisture resistance gives phenolic foam a major advantage over traditional materials like polyurethane or rubber-based insulation.

Its thermal conductivity is among the lowest in the industry, making it one of the most efficient insulators available for both hot and cold pipeline systems.

How It Works to Prevent Moisture and Heat Loss

The performance of Phenolic Pipe Insulation Section in preventing condensation is based on two key properties — thermal resistance and vapor impermeability.

1.Superior Thermal Insulation

Phenolic foam features an extremely low lambda value (around 0.020–0.024 W/m·K), effectively limiting heat transfer through the pipe wall and keeping the external surface warm enough to stop condensation.

2.Closed-Cell Structure

Over 90% of its internal cells are sealed, meaning water vapor cannot penetrate or accumulate inside the insulation.

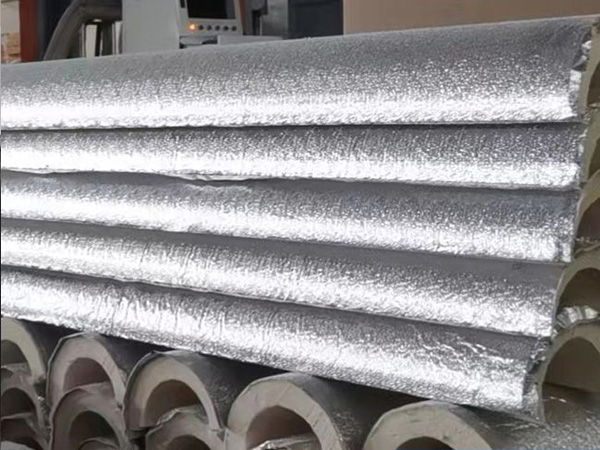

3.Factory-Applied Vapor Barrier

Many phenolic sections come with aluminum foil facing, acting as a continuous moisture shield that maintains dryness even in high-humidity environments.

4.Stable Geometry

The material retains shape and performance even after repeated temperature changes — ensuring that joints remain sealed and effective throughout its lifetime.

Through these combined characteristics, phenolic insulation eliminates condensation risk and preserves pipeline integrity while improving system efficiency.

Main Benefits of Using Phenolic Insulation

1.Outstanding Energy Savings

The extremely low thermal conductivity minimizes heat loss or gain, helping facilities maintain desired temperatures and cut energy bills.

2.Long-Term Dryness

Its closed-cell microstructure resists water penetration, keeping insulation layers dry and effective year after year.

3.Excellent Fire Resistance

Phenolic foam self-extinguishes and produces low smoke emissions, making it one of the safest materials for mechanical and industrial insulation systems.

4.Lightweight and Easy to Handle

Because phenolic foam is lightweight yet rigid, it can be installed quickly, reducing labor time and costs.

5.Durability and Chemical Stability

It resists most industrial chemicals, ensuring stable performance even in harsh working environments.

Together, these advantages make Phenolic Pipe Insulation Sections the preferred solution for projects requiring high-performance and low-maintenance thermal control.

Typical Applications in Industry

Phenolic insulation’s versatility allows it to be applied in nearly every industrial sector where temperature control is critical:

·HVAC systems – For chilled water lines, ducts, and refrigeration piping to eliminate condensation and energy loss.

·Industrial pipelines – To prevent corrosion and moisture damage in chemical or oil processing systems.

·Cold storage and refrigeration – To ensure stable low temperatures and avoid frost formation.

·Public and commercial buildings – In central air-conditioning and mechanical systems for reliable moisture protection.

No matter the application, phenolic insulation consistently provides energy-efficient, moisture-free performance.

Partnering with a Reliable Phenolic Insulation Manufacturer in China

Choosing a phenolic insulation manufacturer in China is a practical way to ensure product quality, supply stability, and cost efficiency. Certified Chinese factories adhere to ISO and ASTM standards, with strict production quality control and testing for density, compressive strength, and water vapor permeability.

A professional China insulation supplier can provide customized dimensions, OEM/ODM support, and bulk order capability, meeting international project requirements. Direct sourcing from a factory eliminates middlemen, offering better pricing and guaranteed consistency across shipments — key advantages for construction contractors and distributors alike.

Conclusion

Condensation control is essential to maintaining efficient, reliable piping systems. The Phenolic Pipe Insulation Section provides a proven defense, combining low thermal conductivity, moisture resistance, and long service life.

When sourced directly from a phenolic insulation manufacturer in China or trusted China insulation supplier, you gain not only dependable product performance but also access to large-scale, cost-effective supply straight from the factory.

For engineers, contractors, and industrial buyers, it’s a simple formula: high-quality insulation, bulk availability, and long-term protection — all in one Phenolic Pipe Insulation Section.

References

GB/T 7714:Bae M, Ahn H, Kang J, et al. Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration[J]. Polymers, 2022, 14(22): 4926.

MLA:Bae, Minjung, et al. "Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration." Polymers 14.22 (2022): 4926.

APA:Bae, M., Ahn, H., Kang, J., Choi, G., & Choi, H. (2022). Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration. Polymers, 14(22), 4926.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...