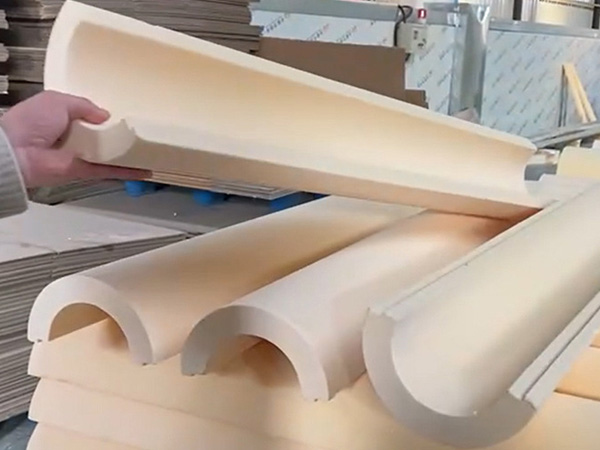

Fire Performance Characteristics of Phenolic Insulation Pipe Sections

2025-06-19 09:03:06

Fire Performance Characteristics of Phenolic Insulation Pipe Sections

1. Inherent Fire-Resistant Chemistry

Phenolic foam's molecular structure contains benzene rings and methylene bridges that require substantial energy to break apart. This results in:

High thermal stability up to 250°C before decomposition begins

Formation of an insulating char layer at 300-400°C that slows heat penetration

Endothermic degradation absorbing 2.5-3.0 kJ/g during combustion

2. Industry Certification Performance

Third-party testing verifies exceptional fire metrics:

Flame Spread Index (FSI): ≤5 (ASTM E84) - outperforms most polymer foams

Smoke Developed Index (SDI): ≤50 (vs. 300-600 for polyurethane)

Oxygen Index (LOI): ≥32% (ISO 4589) indicating self-extinguishing properties

3. Critical Failure Prevention Mechanisms

Non-Dripping Behavior: Maintains structural integrity without molten droplet formation (UL 94 V-0 compliant)

Toxic Gas Suppression: Releases primarily CO₂ and H₂O, with HCN emissions <5ppm (BS 6853 Annex D)

Post-Fire Insulation: Char layer maintains R-value >1.5 m²·K/W even after direct flame exposure

4. Specialized High-Temperature Formulations

For extreme environments:

Ceramic Microsphere-Enhanced: Withstands 400°C for 90 minutes (EN 1363-1)

Graphite-Impregnated: Reduces peak heat release rate by 65% (ISO 5660-1)

Intumescent Coatings: Expand to 5x original thickness when exposed to fire

5. Application-Specific Fire Standards Compliance

Oil/Gas Industry: Meets API 2218 fireproofing requirements for pipe supports

Nuclear Plants: Qualifies for IEEE 383 cable tray fire barriers

Marine Engineering: Certified to IMO FTP Code Part 5 for low flame spread

Maintenance Consideration: Annual infrared inspections recommended to detect any degradation of fireproofing properties in harsh service environments. For tunnels and other confined spaces, specify phenolic foam with additional smoke suppression additives to meet NFPA 502 requirements.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...