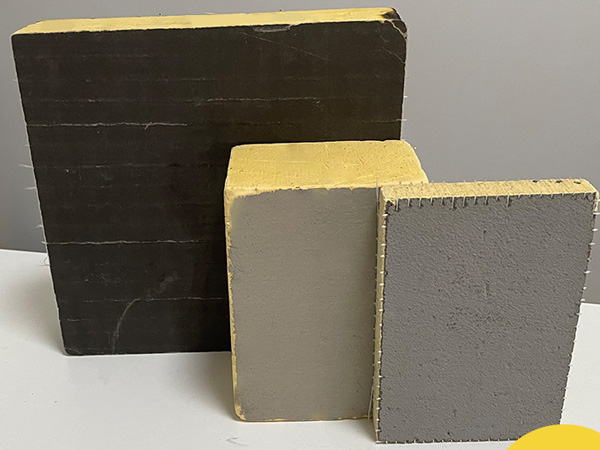

Common Issues of Phenolic Foam Boards Under Different Temperature Conditions

2025-06-18 11:53:28

Common Issues of Phenolic Foam Boards Under Different Temperature Conditions

1. High-Temperature Environments (Above 60°C)

Thermal Degradation: Prolonged exposure to high temperatures may cause resin breakdown, leading to surface cracking or delamination.

Reduced Dimensional Stability: Expansion can occur, causing warping or buckling if panels are tightly constrained.

Adhesive Failure: Some bonding agents lose strength at elevated temperatures, increasing detachment risks.

Off-Gassing: At extreme heat (>120°C), minor volatile emissions may occur (though phenolic foam is inherently low-smoke).

Mitigation:

Use high-temperature-resistant adhesives (e.g., silicone-based).

Ensure ventilation gaps in cladding systems to dissipate heat.

2. Low-Temperature/Cryogenic Conditions (Below -30°C)

Brittleness: The foam may become more fragile, increasing crack risks during handling or impact.

Thermal Contraction: Improperly spaced joints can lead to stress fractures.

Condensation/Icing: In humid cold environments, moisture infiltration may freeze and damage the foam structure.

Mitigation:

Select high-density phenolic foam (≥60 kg/m³) for better low-temperature toughness.

Use flexible sealants to accommodate contraction.

3. Cyclic Temperature Fluctuations

Fatigue Cracking: Repeated expansion/contraction weakens adhesive bonds and panel edges.

Joint Failure: Rigid installations without expansion gaps may split at seams.

Mitigation:

Design with expansion joints (e.g., 5-mm gaps every 3–4 meters).

Prefer elastomeric coatings to absorb movement stresses.

4. Fire Exposure (Short-Term High Heat)

Charring: Phenolic foam forms a protective char layer, but prolonged flames can erode thickness.

Smoke Production: Minimal compared to other foams, but still requires fire-rated assemblies in critical builds.

Mitigation:

Pair with fireproof barriers (e.g., gypsum board) in rated walls.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...