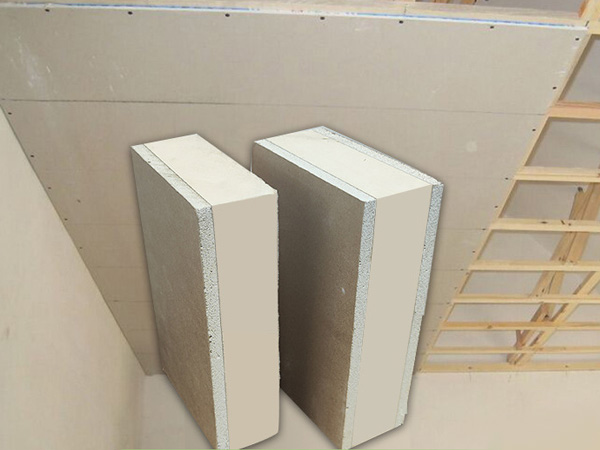

Phenolic aldehyde gypsum composite board

Phenolic aldehyde gypsum composite board is an innovative building material that combines the fire-resistant properties of phenolic foam with the structural stability of gypsum. Designed for interior walls, ceilings, and partition systems, this composite board delivers superior fire protection, thermal insulation, and moisture resistance while maintaining lightweight and easy installation characteristics.

Key Features

Enhanced Fire Resistance

Achieves Class A fire rating (meets GB 8624, EN 13501, or ASTM E84 standards).

Phenolic core significantly delays flame spread and reduces smoke emission.

Thermal & Acoustic Insulation

Low thermal conductivity improves energy efficiency.

Sound-absorbing properties enhance indoor acoustic comfort.

Moisture & Mold Resistance

Modified phenolic-gypsum composition resists humidity, preventing warping or degradation.

Ideal for high-moisture areas (e.g., basements, bathrooms).

Lightweight & High Strength

Easier to handle and install than traditional cement or solid gypsum boards.

Maintains structural integrity under load (compressive strength ≥0.5 MPa).

Eco-Friendly & Low VOC

No formaldehyde emission (meets E0/E1 environmental standards).

Recyclable and reduces construction waste.

Design Flexibility

Compatible with drywall screws, adhesives, and standard finishing systems (paint, tiles, wallpaper).

Applications

Fire-rated partitions in commercial buildings (offices, hotels, hospitals).

Thermal insulation walls/ceilings for energy-efficient homes.

Moisture-resistant linings in kitchens, bathrooms, and basements.

Prefabricated modular construction for rapid installation.

Advantages Over Conventional Boards

✔ Outperforms standard gypsum boards in fire resistance and insulation.

✔ Lighter and more durable than cement-fiber or calcium silicate boards.

✔ Easier to cut and install compared to mineral wool composite panels.

Installation Guidelines

Fix to metal/wood studs using screws or adhesive.

Seal joints with fire-rated tape/compound for continuous protection.

Compatible with most plastering and cladding finishes.

Conclusion

Phenolic aldehyde gypsum composite board redefines interior construction by merging safety, sustainability, and performance. Its dual-functionality as both a fire barrier and thermal insulator makes it a cost-effective choice for modern green buildings and retrofit projects.

For technical specifications or fire-test reports, consult the manufacturer’s documentation.

Note: Performance depends on proper installation. Always follow local building codes for fire-rated assemblies.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05