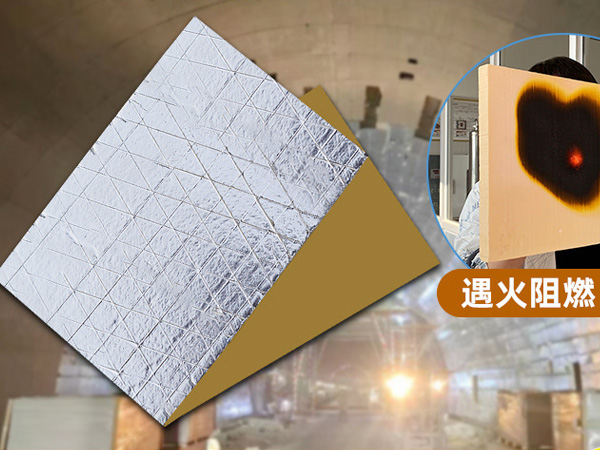

Tunnel thermal insulation phenolic aldehyde thermal insulation board

Tunnel Thermal Insulation Phenolic Aldehyde Board is a high-performance, fire-resistant insulation material specifically engineered for tunnel construction and underground engineering applications. Combining superior thermal properties with exceptional durability, this specialized phenolic foam board provides reliable thermal management and fire protection in demanding tunnel environments.

Key Features

Excellent Thermal Insulation Performance

Ultra-low thermal conductivity (0.020-0.025 W/m·K) effectively reduces heat transfer

Maintains stable insulation performance in varying temperature conditions

Outstanding Fire Resistance

Class A fire rating with flame-retardant properties

Low smoke emission and non-toxic combustion characteristics

Moisture & Chemical Resistance

Closed-cell structure prevents water absorption (<2%)

Resistant to corrosion from tunnel environments (humidity, exhaust fumes, etc.)

High Compressive Strength

Withstands ground pressure and mechanical stress in tunnel applications

Dimensional stability under load (compressive strength ≥150 kPa)

Durable & Long Service Life

Resistant to aging, mold, and bacterial growth

Maintains performance in harsh underground conditions

Lightweight & Easy to Install

Reduces structural load compared to traditional materials

Can be cut and shaped on-site for precise fitting

Applications

Road and rail tunnel insulation systems

Underground passageways and subway tunnels

Underground parking thermal insulation

Hydraulic tunnel temperature control

Mining tunnel insulation

Technical Advantages

✔ Superior thermal efficiency compared to mineral wool or polystyrene

✔ Enhanced fire safety for critical tunnel evacuation scenarios

✔ Moisture resistance prevents performance degradation

✔ Lightweight design simplifies installation in confined spaces

Installation Guidelines

Can be mechanically fixed or adhesively bonded to tunnel linings

Joints should be properly sealed to prevent thermal bridging

Compatible with most tunnel waterproofing systems

Surface can accommodate various finishing treatments as required

Conclusion

Tunnel Thermal Insulation Phenolic Aldehyde Board provides an optimal solution for modern tunnel engineering, combining essential thermal management with critical fire safety performance. Its specialized formulation addresses the unique challenges of underground environments, offering long-term reliability and energy efficiency for infrastructure projects.

For project-specific technical parameters and installation specifications, please consult the manufacturer's engineering data sheets.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05