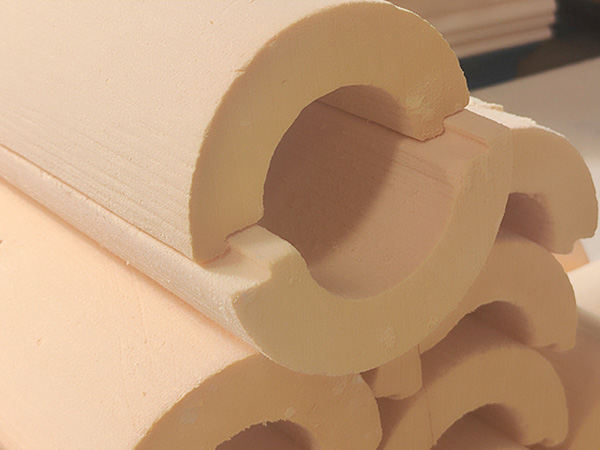

Custom-made Phenolic Insulation Pipe Shell

Our Custom-Made Phenolic Insulation Pipe Shell represents the pinnacle of pipe insulation technology, offering precision-engineered thermal protection for industrial and commercial piping systems. These tailor-made shells combine superior insulation performance with exceptional durability, designed to meet the exact specifications of your piping network.

Key Features

Precision Engineering

Manufactured to match exact pipe diameters and configurations

Available for straight runs, elbows, valves, and complex fittings

Ensures complete coverage without thermal gaps

Exceptional Thermal Performance

Ultra-low thermal conductivity (0.020-0.025 W/m·K)

Maintains stable fluid temperatures in both heating and cooling applications

Significantly reduces energy loss compared to traditional insulation

Superior Fire Protection

Class A fire-rated material with self-extinguishing properties

Minimal smoke emission in fire situations

Ideal for high-risk industrial environments

Moisture and Corrosion Resistance

Closed-cell structure prevents water ingress

Eliminates corrosion under insulation (CUI)

Maintains performance in humid or wet conditions

Durable Construction

Resistant to mechanical damage and compression

Withstands vibration and thermal cycling

Long service life with minimal maintenance

Easy Installation

Pre-formed shells simplify installation

Split design allows for quick fitting and removal

No specialized tools required

Applications

Industrial process piping

HVAC systems (chilled water and steam lines)

Power generation plants

Oil and gas facilities

Marine and offshore installations

District heating systems

Technical Advantages

Up to 30% better thermal efficiency than conventional insulation

50% lighter than mineral wool alternatives

Factory-applied protective facings available

Custom thickness options from 20mm to 100mm

Operating temperature range from -40°C to +120°C

Installation Benefits

The precision-fit design eliminates guesswork and reduces installation time significantly compared to field-applied insulation. Each shell is manufactured to your exact specifications, ensuring perfect coverage of all pipe components including complex fittings and valves.

Why Choose Our Solution?

Our Custom-Made Phenolic Insulation Pipe Shells offer unmatched performance where conventional insulation falls short. By combining superior thermal properties with precise engineering, we deliver a solution that saves energy, reduces maintenance costs, and extends the life of your piping systems.

For optimal results, provide complete pipe specifications including diameters, operating temperatures, and environmental conditions. Our engineering team will recommend the ideal configuration for your specific application.

Note: Actual performance may vary based on installation quality and operating conditions. Consult our technical team for project-specific recommendations.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05