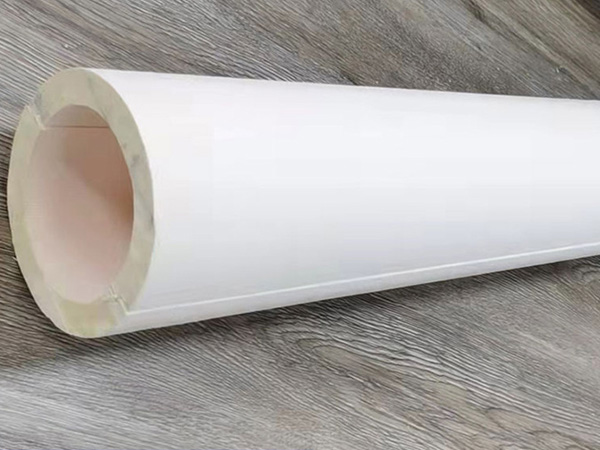

Fire-retardant and fireproof phenolic foam thermal insulation pipe shell

Our fire-retardant and fireproof phenolic foam pipe shell is a cutting-edge insulation solution designed for applications requiring both superior thermal performance and exceptional fire safety. Engineered with advanced phenolic foam technology, it provides reliable protection for pipelines in hazardous environments, industrial facilities, and commercial buildings where fire resistance is critical.

Key Features

Unmatched Fire Resistance

Class A1 Fire Rating (Non-combustible, EN 13501-1)

Flame spread index ≤5 (ASTM E84)

Withstands temperatures up to 300°C without structural failure

Low smoke and toxicity during combustion

Superior Thermal Insulation

Ultra-low thermal conductivity (0.022 W/m·K)

Maintains insulation efficiency even under fire conditions

Reduces heat loss by 40% compared to standard insulation

Durable & Long-Lasting

High-density phenolic foam (≥65 kg/m³)

Compressive strength ≥220 kPa

Resistant to vibration, impact, and mechanical stress

Moisture & Chemical Resistance

Closed-cell structure prevents water absorption (<0.5%)

Resists oils, mild acids, and industrial chemicals

Eliminates corrosion under insulation (CUI)

Easy Installation

Pre-fabricated shells for pipes, valves, and fittings

Lightweight design simplifies handling

Compatible with adhesives or mechanical fasteners

Applications

✔ Oil & gas pipelines (refineries, petrochemical plants)

✔ Power plants (steam lines, boiler systems)

✔ Commercial buildings (fire-rated service shafts)

✔ Tunnels & underground utilities

✔ Marine & offshore installations

Why Choose Our Fireproof Phenolic Pipe Shell?

Dual Protection – Combines thermal insulation with passive fireproofing

Verified Safety – Tested to international fire standards (EN 1363-1, ASTM E84)

Low Maintenance – No reapplication or frequent inspections required

Space-Efficient – Thinner than traditional fireproofing materials

Technical Specifications

Operating Temperature: -40°C to +300°C (intermittent)

Standard Thicknesses: 25mm, 40mm, 50mm (custom available)

Pipe Diameters: 15mm to 500mm

Facing Options: Aluminum foil, stainless steel, or fiberglass reinforced

Installation Guidelines

Ensure clean, dry pipe surfaces before installation.

Use high-temperature adhesive or mechanical fasteners.

Seal joints with fire-rated tape or mastic.

For extreme conditions, consult our technical team for specialized solutions.

Conclusion

Our fire-retardant and fireproof phenolic foam pipe shell sets a new standard for safety and efficiency in pipeline insulation. It delivers reliable thermal performance, unmatched fire resistance, and long-term durability, making it the ideal choice for high-risk environments.

Contact us for custom solutions tailored to your project requirements!

Note: Fire resistance duration depends on system design, including supports and penetrations. Always follow local fire safety regulations.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05