Closed-Cell Structure and Its Impact on Phenolic Foam Board Performance

2026-02-06 22:30:14

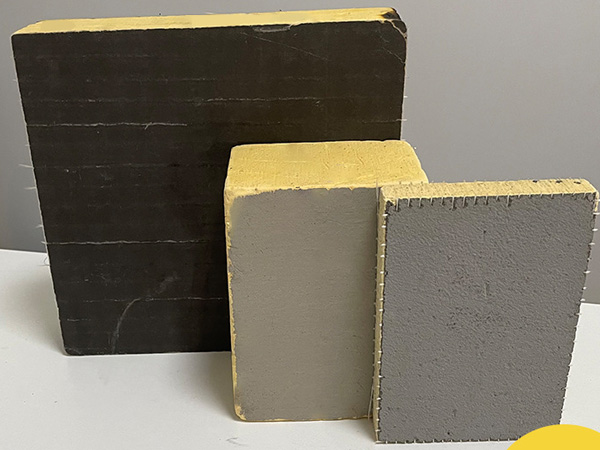

Phenolic Foam Board has become a preferred insulation solution in modern construction, HVAC systems, and industrial facilities because of its excellent thermal resistance, fire behavior, and long-term stability. One of the most important reasons behind its performance is the closed-cell structure inside the material. This microstructure controls how heat, moisture, and mechanical forces interact with the board.

Supported by Manufacturer-controlled Production and Factory-scale bulk supply, Phenolic Foam Board is engineered with uniform cell distribution to deliver consistent performance across large projects. This article explains how closed-cell structure influences phenolic foam board behavior and why it matters in real-world applications.

Introduction to Phenolic Foam Board Technology

Energy efficiency and safety are key requirements in today’s buildings and industrial systems. Insulation materials must not only reduce heat transfer but also resist fire, moisture, and mechanical stress. Phenolic Foam Board addresses these needs by combining lightweight construction with strong thermal and safety performance.

In professional Manufacturer environments, Production focuses on resin formulation, foaming control, and curing conditions. Factory output ensures phenolic foam boards meet strict thickness, density, and surface quality standards for bulk supply to global markets.

What Is a Closed-Cell Structure?

A closed-cell structure means that individual foam cells are sealed and not interconnected. Each microscopic cell contains trapped gas or air, creating millions of isolated pockets inside the Phenolic Foam Board.

Key characteristics of closed cells include:

·Limited air movement

·Low water absorption

·Stable internal pressure

·High resistance to heat flow

During Production, Manufacturer processes precisely control expansion so Factory-made phenolic foam boards maintain uniform cell size and density across the panel.

Why Structure Matters in Insulation Materials

The internal structure of insulation defines how energy and moisture move through it. Open-cell materials allow air and vapor to circulate, which increases heat transfer and moisture uptake. In contrast, the closed-cell design of Phenolic Foam Board restricts convection and diffusion.

Structural advantages include:

·Reduced thermal bridging

·Improved vapor resistance

·Enhanced mechanical integrity

·Longer service life

Manufacturer-controlled Production ensures Factory bulk supply products maintain consistent closed-cell ratios for predictable performance in construction and HVAC projects.

Thermal Efficiency Driven by Closed Cells

Thermal performance is the core function of any insulation board. The closed-cell structure of Phenolic Foam Board traps air and limits conductive and convective heat transfer.

Benefits for thermal efficiency:

·Low thermal conductivity

·Stable insulation value over time

·Reduced heat gain and loss

·Improved energy savings

By optimizing cell density during Production, Manufacturer operations allow Factory-supplied phenolic foam boards to deliver reliable thermal resistance for large-scale building envelopes and pipeline systems.

Fire Safety and Smoke Suppression Benefits

Fire behavior is critical in commercial and industrial applications. Phenolic Foam Board offers improved fire performance compared with many traditional foams due to its chemical structure and closed-cell design.

Safety advantages include:

·Low flame spread

·Reduced heat release

·Minimal smoke generation

·Improved evacuation conditions

Factory-controlled Production integrates material formulation and curing processes so Phenolic Foam Board achieves balanced fire safety and structural performance in demanding environments.

Moisture Resistance and Dimensional Stability

Moisture infiltration is a common cause of insulation failure. Because closed cells are sealed, Phenolic Foam Board resists water penetration and vapor diffusion.

Moisture-related benefits:

·Low water absorption

·Resistance to condensation

·Stable dimensions under humidity changes

·Reduced risk of corrosion under insulation

Manufacturer Production applies surface finishing and density calibration so Factory bulk supply boards maintain shape and performance throughout their service life.

Mechanical Strength and Long-Term Durability

Beyond thermal and moisture performance, Phenolic Foam Board must withstand mechanical stress from installation and operation. Closed-cell structures distribute loads evenly across the foam matrix.

Mechanical advantages include:

·High compressive strength

·Resistance to deformation

·Structural stability

·Long-term performance retention

Through controlled Production, Manufacturer systems ensure Factory-produced phenolic foam boards achieve reliable mechanical behavior for walls, ducts, and industrial enclosures.

Manufacturer Production and Factory Bulk Supply

Consistent quality starts with manufacturing. Professional Manufacturer operations manage:

·Resin formulation

·Foam expansion control

·Cell size calibration

·Panel cutting and finishing

·Surface treatment

Factory bulk supply ensures:

·Uniform density

·Accurate thickness

·Stable closed-cell ratios

·Reliable packaging and logistics

This integrated Production system allows Phenolic Foam Board to be delivered in large volumes while maintaining predictable performance across global projects.

Applications of Phenolic Foam Board

Because of its closed-cell advantages, Phenolic Foam Board is widely applied in:

·Building wall and roof insulation

·HVAC duct systems

·Industrial pipeline protection

·Cleanroom construction

·Equipment enclosure insulation

With Manufacturer Production capacity and Factory bulk supply, phenolic foam boards support both residential and industrial insulation demands efficiently.

How to Select the Right Phenolic Foam Board

When choosing Phenolic Foam Board, consider:

·Thermal performance requirements

·Fire safety standards

·Moisture exposure levels

·Mechanical load conditions

·Installation environment

Coordinating with Manufacturer Production planning ensures Factory-supplied boards match the application’s technical and durability needs.

Conclusion: Closed-Cell Structure Defines Phenolic Foam Board Performance

Phenolic Foam Board owes much of its outstanding performance to its closed-cell structure. By trapping air, blocking moisture, and distributing mechanical loads, closed cells enhance thermal efficiency, fire safety, and long-term durability.

Backed by Manufacturer-controlled Production and Factory-level bulk supply, Phenolic Foam Board delivers consistent quality from fabrication to installation. Choosing phenolic insulation is not only about material selection—it is about leveraging closed-cell technology to achieve safer, more energy-efficient, and more reliable insulation systems with professional Phenolic Foam Board solutions.

References

GB/T 7714:Al-Homoud M S. Performance characteristics and practical applications of common building thermal insulation materials[J]. Building and environment, 2005, 40(3): 353-366.

MLA:Al-Homoud, Mohammad S. "Performance characteristics and practical applications of common building thermal insulation materials." Building and environment 40.3 (2005): 353-366.

APA:Al-Homoud, M. S. (2005). Performance characteristics and practical applications of common building thermal insulation materials. Building and environment, 40(3), 353-366.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...