Integrated Thermal Systems: Using Phenolic Foam Boards and Pipe Sections Together

2025-11-14 14:44:38

Efficient energy management has become a cornerstone of modern industrial and building design. The ability to reduce thermal losses and maintain stable temperature control across different components is crucial for sustainability and long-term performance. One of the most effective ways to achieve this balance is through the combined use of phenolic pipe insulation sections and phenolic insulation boards.

As a specialized phenolic insulation manufacturer, supported by advanced production capacity and bulk supply infrastructure, we are committed to delivering integrated insulation systems that meet global energy efficiency standards. Let’s explore how these materials work together to create a seamless thermal protection network.

What Are Phenolic Pipe Insulation Sections?

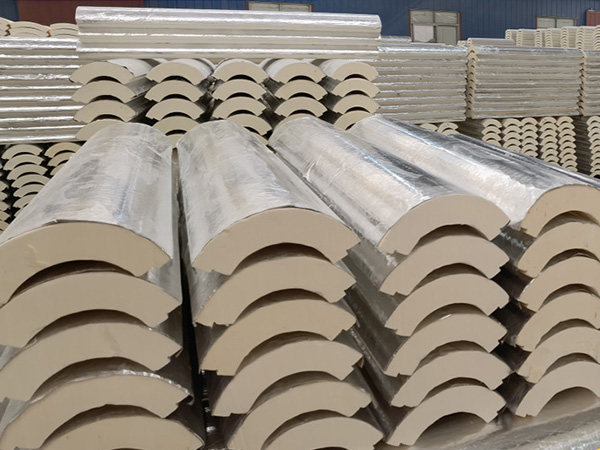

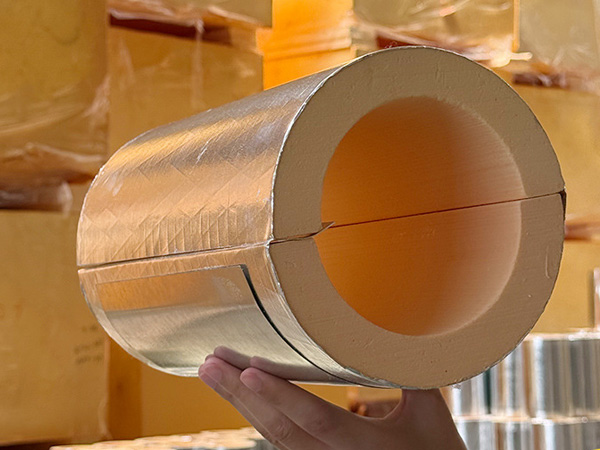

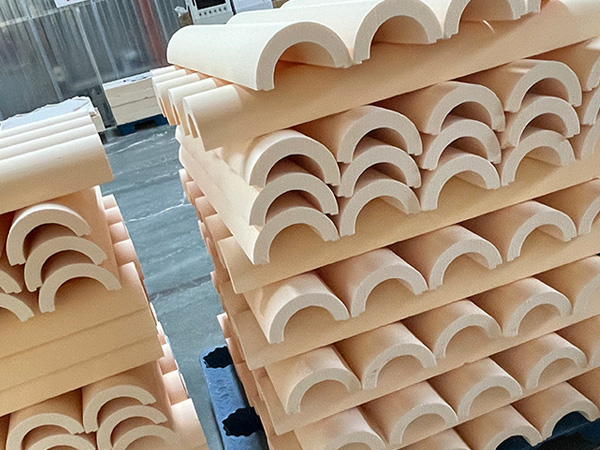

Phenolic pipe insulation sections are pre-formed cylindrical shells made from rigid phenolic foam. This closed-cell material exhibits excellent thermal resistance, minimal water absorption, and exceptional fire performance. Designed to fit around pipes in HVAC systems, industrial plants, and district heating lines, these sections form a critical component of modern thermal management.

Because of their ultra-low thermal conductivity (as low as 0.021 W/m·K), phenolic pipe sections achieve high insulation performance with thin walls — saving both material and space.

Major benefits include:

·Excellent heat retention and energy savings

·Resistance to moisture, corrosion, and vapor penetration

·Non-combustible behavior meeting global safety standards

·Long-lasting dimensional stability and easy installation

Phenolic Foam Boards and Their Role in Thermal Systems

Where pipelines require circular insulation, Phenolic Foam Boards serve as the flat-surface equivalent. These boards are used to insulate walls, tanks, ducts, or equipment surfaces, ensuring the same thermal efficiency as pipe insulation sections.

Phenolic Foam Boards are known for their:

·High insulation value per unit thickness

·Moisture and chemical resistance in harsh environments

·Versatility across building and industrial projects

·Easy customization and cutting for various surface types

By integrating Phenolic Foam Boards with phenolic pipe insulation sections, an unbroken thermal envelope can be created, maintaining consistent insulation across every part of a system.

The Science Behind Integration

Thermal bridging — the unwanted escape of heat through gaps or mismatched materials — is a major issue in both buildings and pipelines. By using Phenolic Foam Boards and pipe insulation sections together, designers can eliminate these weak points.

When integrated correctly, both materials form a continuous insulation layer, providing:

1.Uniform Thermal Performance

Identical insulation characteristics mean no conductivity mismatch between flat and round surfaces.

2.Reduced Energy Losses

Combined phenolic systems minimize heat gain and loss across complex geometries, optimizing energy use.

3.Condensation Control

Consistent insulation prevents surface condensation and corrosion under insulation (CUI).

4.Extended Service Life

A continuous thermal barrier reduces wear on pipelines, ducts, and equipment, lowering maintenance needs.

Applications Across Sectors

The combination of phenolic pipe insulation sections and Phenolic Foam Boards is widely used in:

·District heating and cooling pipelines

·Oil, gas, and petrochemical facilities

·HVAC ductwork and mechanical services

·Food and pharmaceutical production systems

·Energy-efficient building façades and plant rooms

In all these settings, a well-designed phenolic insulation system enhances both energy efficiency and operational reliability.

Advantages of Working with a Professional Manufacturer

Choosing a certified phenolic insulation manufacturer is crucial to achieving consistent results. Manufacturers with full production capacity and bulk supply capabilities can provide:

·Custom-designed insulation sizes and densities

·Certified fire and thermal test data

·Stable supply for large-scale infrastructure projects

·Expert guidance from design to installation

Partnering directly with the manufacturer guarantees material traceability, quality control, and compatibility between phenolic components. This integration ensures long-term efficiency, safety, and performance.

Sustainability and Environmental Performance

Phenolic foam insulation is recognized for its sustainability advantages. It offers one of the lowest thermal conductivities among rigid foams and has minimal impact on global warming potential.

By integrating phenolic pipe insulation sections and Phenolic Foam Boards, designers can reduce total system energy loss, improve building envelope performance, and lower carbon emissions. These systems also help meet international sustainability certifications, such as LEED, BREEAM, and ISO 14001.

Conclusion

The integration of Phenolic Foam Boards and phenolic pipe insulation sections represents a cutting-edge approach to achieving thermal continuity in both industrial and architectural applications. This dual-system solution ensures consistent performance, reduced energy costs, and superior fire and moisture protection.

As a dedicated phenolic insulation manufacturer, equipped with advanced production facilities and bulk supply capabilities, we provide a complete range of phenolic insulation materials tailored to modern efficiency and sustainability standards.

Whether for HVAC pipelines, chemical plants, or energy-efficient buildings, integrating Phenolic Foam Boards and pipe insulation sections is the smart way to build durable, high-performance thermal systems that last.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...