Phenolic Insulation Board: Choosing the Right Thickness

2025-10-05 12:57:50

Among advanced building insulation solutions, Phenolic Insulation Board has become a top choice due to its impressive thermal resistance, slim profile, and reliable fire safety. For energy-conscious projects—from commercial buildings to residential retrofits—its role is central.

One of the most decisive factors in its effectiveness is thickness. The correct thickness of Phenolic Insulation Board not only determines compliance with energy codes but also influences cost efficiency, interior space, and long-term performance. To maximize benefits, many contractors and distributors secure supply directly from a China manufacturer with bulk supply capacity, ensuring both affordability and consistent quality.

What Is Phenolic Insulation Board?

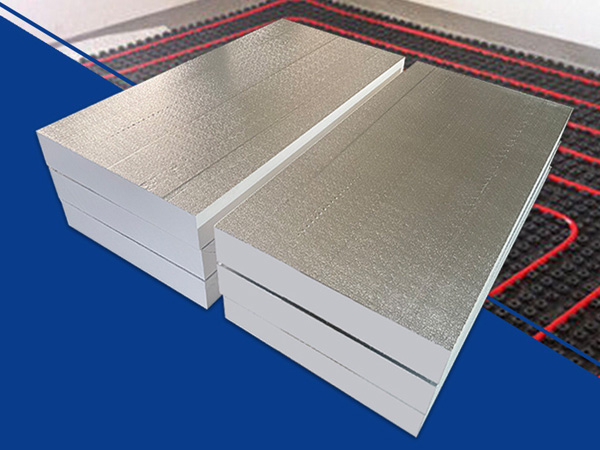

Phenolic boards are rigid panels produced by foaming phenolic resin into a closed-cell structure. They are often finished with aluminum foil or fiberglass layers for enhanced stability and moisture protection.

Distinct Features

·Outstanding Thermal Efficiency: Conductivity levels as low as 0.020–0.023 W/m·K.

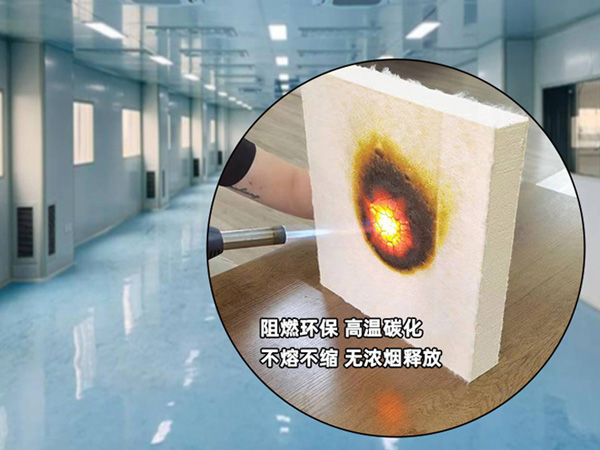

·High Fire Resistance: Produces very little smoke or toxic gases when exposed to flame.

·Moisture Control: Closed-cell design prevents water penetration and maintains insulation values.

·Durability: Resistant to environmental fluctuations, making it suitable for long-term use.

Why Thickness Selection Matters

1.Energy Efficiency

Greater thickness lowers U-values, enabling buildings to meet passive house or net zero performance standards.

2.Compliance with Codes

Regional building regulations define minimum insulation thicknesses across different applications.

3.Spatial Considerations

Correct selection avoids wasting usable space while maintaining insulation performance.

4.Economic Balance

Overuse of material increases upfront costs, while underuse leads to energy loss over time.

Application-Based Thickness Guidelines

External Walls

A thickness of 50–80 mm is common, providing energy efficiency without disrupting façade design.

Internal Partitions

Usually 25–50 mm is sufficient, ensuring comfort without significantly reducing room size.

Roofing Systems

Roofs are a major channel of heat exchange. 80–120 mm is typically recommended for both pitched and flat roofs.

Floors & Basements

50–100 mm balances thermal protection with ground moisture resistance.

HVAC Ducting

Here, fire performance is critical. 20–40 mm boards deliver adequate thermal resistance and enhanced safety.

Factors to Keep in Mind

·Climate Zone: Colder regions demand thicker insulation.

·Building Performance Targets: Passive and net zero projects require higher insulation standards.

·Load Conditions: Floors and roofs may need boards with higher compressive strength.

·Integration: Selected thickness must work seamlessly with finishes, renders, or cladding systems.

Why Work with a China Manufacturer?

Sourcing Phenolic Insulation Board from a China factory that supports bulk supply provides distinct advantages:

·Reliable Quality: Factories often adhere to ISO, EN, or ASTM benchmarks.

·Lower Costs: Direct bulk orders minimize intermediary expenses.

·Tailored Solutions: Options for thickness, dimensions, and facing materials.

·Stable Supply: Large-scale production supports continuous procurement for distributors and large projects.

Conclusion

Choosing the right thickness of Phenolic Insulation Board is key to delivering buildings that are energy-efficient, safe, and cost-effective. Whether applied to walls, roofs, floors, or HVAC systems, correct thickness ensures optimal performance and compliance.

For distributors and contractors, sourcing directly from a China manufacturer with bulk supply capacity guarantees affordability, steady availability, and reliable performance.

Ultimately, Phenolic Insulation Board remains more than just an insulation solution—it is a strategic choice for sustainable construction and long-term building success.

References

GB/T 7714:Li X, Tingley D D. A whole life, national approach to optimize the thickness of wall insulation[J]. Renewable and Sustainable Energy Reviews, 2023, 174: 113137.

MLA:Li, X., and D. Densley Tingley. "A whole life, national approach to optimize the thickness of wall insulation." Renewable and Sustainable Energy Reviews 174 (2023): 113137.

APA:Li, X., & Tingley, D. D. (2023). A whole life, national approach to optimize the thickness of wall insulation. Renewable and Sustainable Energy Reviews, 174, 113137.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...