Phenolic Pipe Shell Manufacturer

2026-02-19 10:40:59

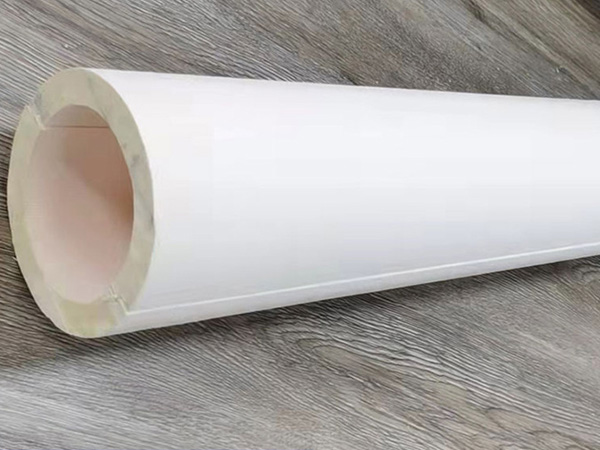

As insulation requirements continue to increase across HVAC, industrial piping, and energy-related projects, the demand for reliable and high-performance pipe insulation materials has grown steadily. A professional Phenolic Pipe Shell Manufacturer plays a critical role in supplying insulation solutions that combine thermal efficiency, fire safety, and long-term durability. Backed by stable production capacity and the ability to support bulk supply, manufacturers of phenolic pipe shells provide essential materials for modern insulation systems.

Role of a Phenolic Pipe Shell Manufacturer

A Phenolic Pipe Shell Manufacturer focuses on the design, production, and supply of phenolic foam pipe shells used for thermal and heat insulation. These manufacturers are responsible for:

Controlling raw material selection to ensure consistent insulation performance

Maintaining standardized production processes

Delivering stable quality suitable for engineering and industrial applications

Through continuous production optimization, manufacturers ensure that phenolic pipe shells meet the insulation demands of various pipe systems operating under different temperature and environmental conditions.

Production and Manufacturing Capabilities

Modern phenolic pipe shell manufacturing relies on efficient and scalable **production lines**. From foam formulation to shaping and curing, each step is carefully controlled to achieve uniform density and precise dimensions.

Key production advantages include:

Batch production capability** to support large-scale projects

Consistent thickness and inner diameter accuracy

Stable output for long-term supply contracts

Support for customized specifications based on pipe size and insulation requirements

This production-oriented approach allows manufacturers to serve HVAC contractors, industrial users, and infrastructure projects with reliable delivery schedules.

Applications of Phenolic Pipe Shells

Products supplied by a Phenolic Pipe Shell Manufacturer are widely used in:

HVAC hot and cold water pipe systems

Central air conditioning pipelines

Industrial process piping

Energy and utility infrastructure

Commercial and public building insulation systems

Phenolic pipe shells are especially valued in applications where thermal insulation, fire resistance, and dimensional stability are required.

Performance Characteristics

Phenolic pipe shells manufactured under controlled production conditions offer several performance advantages:

Low thermal conductivity**, supporting efficient heat insulation

Fire-resistant properties**, enhancing system safety

Moisture resistance**, reducing condensation risks

Lightweight structure**, enabling easier handling and installation

Long service life**, suitable for continuous operation environments

Manufacturers emphasize consistent performance to ensure insulation systems remain reliable over time.

Manufacturer Support and Supply Capability

As a dedicated **manufacturer**, long-term cooperation with clients is supported by:

Stable raw material sourcing

Continuous production scheduling

Flexible order quantities, from small batches to bulk supply

Technical support aligned with project requirements

This manufacturing and supply model ensures that phenolic pipe shells can be delivered efficiently for both standard and customized insulation solutions.

Conclusion

A professional **Phenolic Pipe Shell Manufacturer** provides more than just insulation products—it delivers stable production, consistent quality, and dependable supply for modern insulation systems. With strong manufacturing capabilities and a focus on performance-driven materials, phenolic pipe shell production continues to support HVAC, industrial, and energy-related projects worldwide.

References

1. Thermal Insulation Materials for Pipe Systems

2. Phenolic Foam Technology in Industrial Insulation

3. Fire-resistant Insulation Materials for HVAC Applications

4. Performance Evaluation of Pipe Insulation Systems

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...