Engineering Applications of Elastomeric Foam (Rubber-Plastic Boards) in Acoustic Noise Reduction for Sports Venues

2025-06-18 18:17:18

Engineering Applications of Elastomeric Foam (Rubber-Plastic Boards) in Acoustic Noise Reduction for Sports Venues

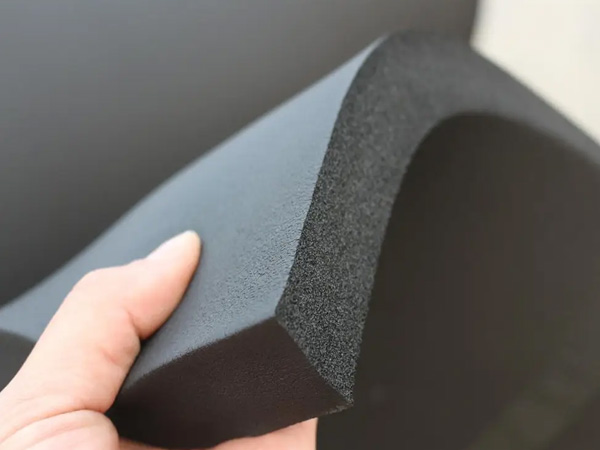

Elastomeric foam is widely used in sports venues for its superior sound absorption, vibration damping, and thermal insulation properties. Below is a detailed analysis of its engineering applications in noise control for stadiums and arenas.

1. Key Acoustic Performance Advantages

Broad-Spectrum Sound Absorption

Effectively absorbs mid-to-high-frequency noise (500–5000 Hz), including crowd cheers, PA systems, and mechanical equipment sounds4.

Achieves a Noise Reduction Coefficient (NRC) of 0.7–0.9, outperforming traditional materials like fiberglass or mineral wool5.

Vibration Damping

Reduces structure-borne noise from foot impacts, HVAC systems, and mechanical vibrations3.

Moisture & Fire Resistance

Closed-cell structure prevents moisture absorption, crucial for indoor pools and ice rinks1.

Meets Class B1 (GB 8624) / Euroclass B-s1,d0 fire safety standards, minimizing toxic fume release5.

2. Primary Applications in Sports Venues

(1) Ceiling & Wall Panels

Suspended Acoustic Baffles

Lightweight elastomeric foam panels are hung from ceilings to reduce reverberation time (RT60) in large arenas4.

Customizable shapes (e.g., curved, prismatic) enhance both acoustics and aesthetics7.

Wall-Mounted Sound Absorbers

Installed behind seating areas to minimize echo and improve speech clarity for announcements2.

(2) Flooring Underlayment

Impact Noise Reduction

High-density (≥80 kg/m³) foam under hardwood or synthetic floors dampens footfall and ball-bounce noise3.

Combined with mass-loaded vinyl (MLV) for low-frequency noise control (e.g., drumming from bleachers)8.

(3) HVAC & Ductwork Insulation

Noise from Air Handling Units (AHUs)

Wrapping ducts with elastomeric foam reduces airborne noise transmission by 15–20 dB1.

Self-adhesive variants simplify installation in tight spaces6.

(4) Seating & Barrier Systems

Modular Acoustic Barriers

Deployed around VIP boxes or media zones to isolate chatter and improve broadcast audio quality7.

Seat Back Panels

Thin (5–10mm) foam layers absorb reflected sound waves between rows4.

3. Installation Best Practices

Seamless Integration

Use butyl tape or elastomeric sealant for airtight joints, preventing sound leakage2.

Hybrid Material Systems

Combine with microperforated panels (MPP) for targeted frequency absorption5.

Structural Decoupling

Isolate foam panels using resilient channels to prevent flanking noise8.

4. Emerging Innovations

Smart Acoustic Foam

Embedded sensors adjust porosity in real-time to optimize noise absorption for different events (e.g., concerts vs. basketball)6.

Recyclable Formulations

Bio-based elastomers (e.g., soy-derived) are being tested for sustainable noise control5.

For Olympic-grade venues, elastomeric foam is often paired with nanocoated acoustic panels to meet stringent noise standards6.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...