Understanding Moisture Resistance in Phenolic Insulation Board

2025-09-11 14:20:35

Modern buildings demand insulation that performs well not just thermally, but also against moisture. Among advanced solutions, Phenolic Insulation Board has earned recognition for its ability to remain effective even in challenging humid or wet environments. This resistance to water intrusion allows it to maintain thermal performance while protecting structures from long-term damage.

In this article, we’ll examine how phenolic boards resist moisture, the benefits this brings across different climates, and how reliable bulk supply from China manufacturers supports global construction needs.

Why Moisture Resistance Defines Long-Term Insulation Value

Moisture is one of the main enemies of insulation. When water seeps in, it disrupts the material’s structure, reducing efficiency and creating secondary issues like mold or corrosion. For builders and occupants, poor resistance to water often leads to:

Greater energy losses as wet insulation becomes less effective.

Shorter service life of materials, requiring earlier replacement.

Compromised indoor air quality due to mold or mildew growth.

This is why the moisture resistance of Phenolic Insulation Board is considered one of its most important advantages.

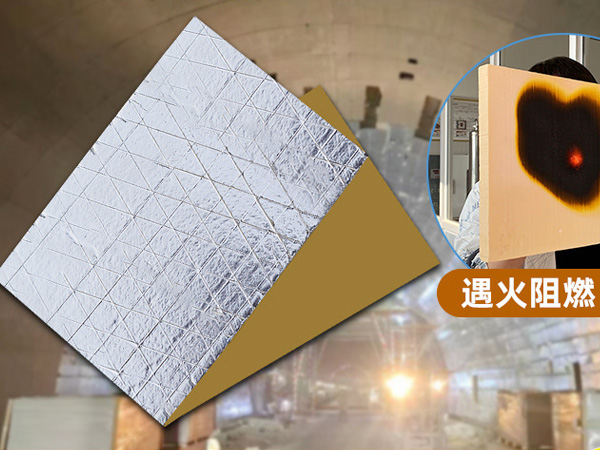

How Phenolic Insulation Board Fights Moisture

The structure of phenolic boards is designed to minimize water intrusion. Several factors explain its resilience:

Closed-Cell Structure

The foam’s tightly sealed cells limit liquid penetration, keeping the core dry even under exposure.

Vapor Control

Phenolic material slows vapor transfer, protecting against condensation inside walls or roofs.

Preserved Thermal Conductivity

Unlike many materials that lose efficiency when damp, phenolic boards retain stable thermal performance.

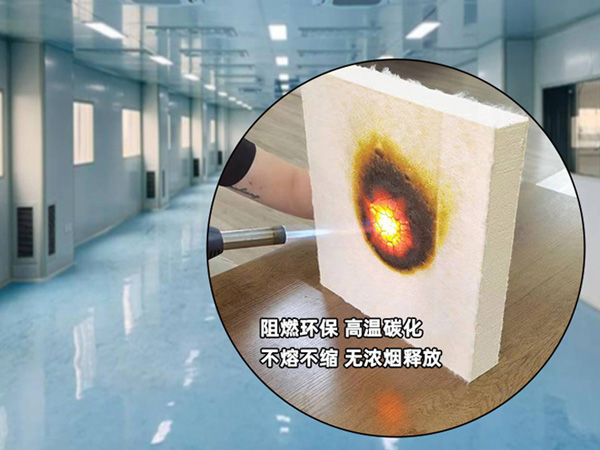

Resistance to Microbial Growth

With little retained moisture, conditions for mold or bacteria growth are greatly reduced.

Real-World Performance in Various Climates

Coastal Regions

In areas with constant humidity and salt-laden air, phenolic boards continue performing without significant swelling or degradation.

Tropical Environments

During heavy rains and prolonged wet seasons, phenolic insulation maintains its integrity, unlike many common alternatives.

Cold Climates with Condensation Risks

Freezing weather often leads to condensation within building envelopes. Phenolic boards slow vapor passage, reducing structural risks.

Applications That Benefit Most

The moisture resistance of Phenolic Insulation Board makes it suitable for demanding uses, such as:

Roof insulation exposed to rainfall or snow.

Exterior wall systems subject to wind-driven rain.

Refrigeration and cold storage, where condensation is constant.

HVAC ducting in humid regions.

Its durability across these settings makes it a preferred choice for contractors prioritizing long-term building health.

Supply Considerations and China Manufacturing

Global construction projects rely not only on performance but also on steady supply chains. Many professionals source through China factories offering bulk phenolic insulation board supply, which ensures availability while maintaining international quality standards.

By working directly with large-scale Chinese manufacturers, distributors and builders gain access to consistent products at competitive costs, making large projects easier to manage.

Best Practices for Installation and Maintenance

Seal edges and joints properly to prevent moisture intrusion.

Avoid prolonged exposure to standing water during handling or installation.

Combine with vapor barriers where climates are extremely humid.

Schedule inspections to confirm that insulation remains intact and dry over time.

Conclusion: Why Moisture Resistance Matters

From tropical storms to cold-weather condensation, Phenolic Insulation Board demonstrates strong resilience against moisture — a property that sets it apart in modern construction. By resisting water absorption, maintaining thermal stability, and preventing mold, it safeguards buildings and extends material lifespan.

For large projects, reliable sourcing is essential. Partnering with China manufacturers that provide bulk phenolic insulation board supply offers both cost efficiency and product consistency. Ultimately, moisture resistance is not just a feature — it is one of the core reasons why phenolic insulation continues to lead the way in high-performance building materials.

References

GB/T 7714:Mattila H P. Moisture behavior of building insulation materials and good building practices[J]. EPS, 2017, 15: 31.

MLA:Mattila, Hannu-Petteri. "Moisture behavior of building insulation materials and good building practices." EPS 15 (2017): 31.

APA:Mattila, H. P. (2017). Moisture behavior of building insulation materials and good building practices. EPS, 15, 31.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...