Key Specs for Phenolic Insulation Board: Density and Strength Guide

2025-07-25 18:36:25

1. What is Phenolic Insulation Board?

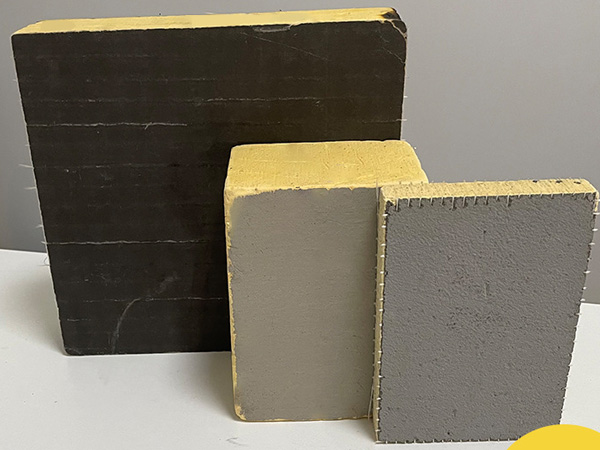

Phenolic insulation board is a new-generation, highly efficient thermal insulation material, widely used in construction, industrial applications, and cold chain logistics. Made from phenolic resin as the base material and processed through special manufacturing techniques, it offers excellent thermal insulation, fire resistance, and high mechanical strength. Compared to traditional insulation materials like polyurethane (PU) and polystyrene (EPS), phenolic insulation board stands out for its superior compressive strength and density.

When selecting phenolic insulation board, two critical parameters that directly affect insulation performance, durability, and ease of construction are density and compressive strength. This article delves into these two parameters and provides practical advice for choosing the right phenolic insulation board.

2. Density of Phenolic Insulation Board: Importance and Selection Criteria

The density of phenolic insulation board is one of its key physical properties and is typically measured in kilograms per cubic meter (kg/m³). A higher density board generally offers better compressive strength and mechanical stability but might have a slightly lower insulation performance. In contrast, a lower density board provides superior thermal insulation but may lack the necessary compressive strength and is more prone to deformation under heavy loads.

Density and Thermal Insulation Performance

Density and thermal conductivity (thermal insulation performance) are inversely related in phenolic insulation board. A lower density usually means more air pockets, which help slow down heat transfer, resulting in better insulation. For most applications, phenolic insulation boards with densities ranging from 40–80 kg/m³ strike a good balance between thermal performance and compressive strength.

Density and Compressive Strength

The relationship between density and compressive strength in phenolic insulation boards is complex. Generally, phenolic boards with higher density tend to have greater compressive strength because the material structure is more compact, making it more resistant to external pressure. If your project requires insulation boards to withstand significant pressure or heavy loads, higher-density phenolic boards are likely the better choice.

3. Compressive Strength: Durability and Applications of Phenolic Insulation Board

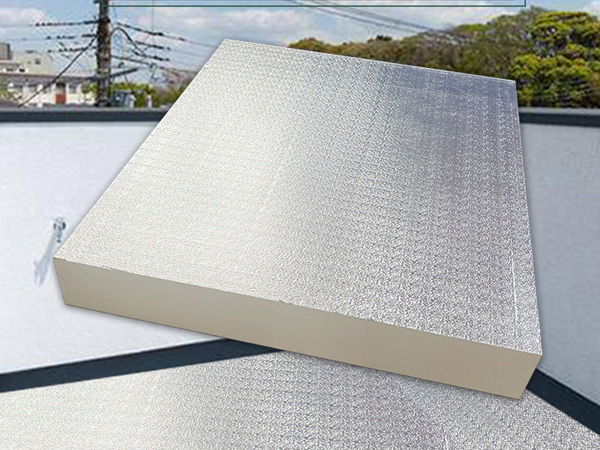

Compressive strength is a vital indicator of phenolic insulation board performance, especially in applications where the material needs to bear loads, such as on floors, roofs, or walls exposed to pressure. The compressive strength directly determines the material’s durability and ability to maintain its insulating properties under stress.

Compressive Strength and Application Scenarios

Compressive strength is typically measured in megapascals (MPa), with values ranging from 0.1 MPa to 0.4 MPa. The exact strength depends on the board's density, resin content, and manufacturing process.

Low Compressive Strength (0.1–0.2 MPa): Suitable for low-load applications such as interior walls, ceilings, and non-weight-bearing structures.

High Compressive Strength (0.3–0.4 MPa): Ideal for areas with significant pressure, such as floors, roofs, or areas where heavy equipment might be used.

Phenolic boards with higher compressive strength are designed to resist damage during construction and remain stable over time, making them a reliable choice for cold chain logistics, high-rise buildings, or any application where long-term durability is crucial.

4. How to Choose the Right Phenolic Insulation Board?

When selecting phenolic insulation board, it's essential to consider the actual application requirements, load demands, temperature fluctuations, and budget. Here are the critical factors to guide your choice:

Density Selection: For most residential or commercial buildings, phenolic insulation boards with a density of 50–70 kg/m³ are usually sufficient. If you require better thermal insulation, go for a lower-density board. For high-load areas, choose a higher-density product.

Compressive Strength: Choose an appropriate compressive strength based on the application. For high-load areas, opt for boards with higher compressive strength to ensure long-lasting stability and durability.

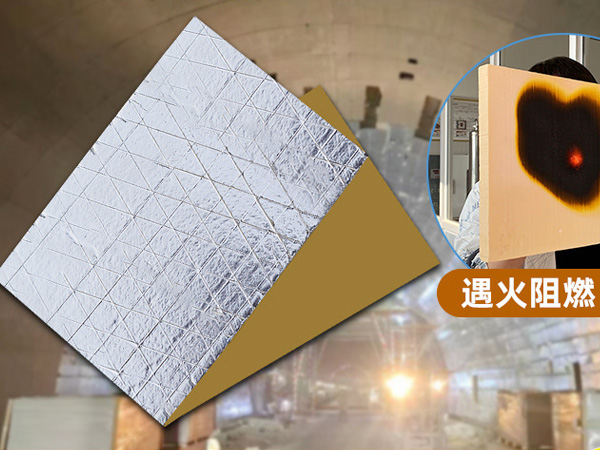

Fire Resistance: Ensure that the phenolic insulation board meets the relevant building fire safety standards, as fire resistance is one of its key advantages.

Environmental Adaptability: Confirm that the phenolic board can withstand local climatic conditions without performance degradation due to temperature fluctuations.

5. Conclusion: Why Choose Phenolic Insulation Board Over Competitors

In summary, phenolic insulation board stands out for its excellent density, compressive strength, heat resistance, and fireproof properties, making it a top choice among insulation materials. Compared to traditional materials like polyurethane and polystyrene, phenolic boards offer better thermal insulation and can withstand higher pressure loads, making them ideal for various applications. If you prioritize long-term performance, durability, and cost-effectiveness in your insulation project, phenolic insulation board is the material for you.

By choosing high-quality phenolic insulation board, you will ensure that your construction projects deliver superior thermal performance and structural integrity. Whether it's for residential buildings, commercial properties, or industrial applications, phenolic insulation board is your best choice to outperform the competition.

By understanding the density and compressive strength of phenolic insulation boards and considering your specific needs, you can ensure the best selection for your project. We hope this guide helps you make a well-informed decision when purchasing phenolic insulation boards.

References

GB/T 7714:Chen X, Yu W, Ma L, et al. Mechanical properties and thermal characteristics of different-density phenolic foams[J]. Journal of Thermal Analysis and Calorimetry, 2021, 144(2): 393-401.

MLA:Chen, Xiaokun, et al. "Mechanical properties and thermal characteristics of different-density phenolic foams." Journal of Thermal Analysis and Calorimetry 144.2 (2021): 393-401.

APA:Chen, X., Yu, W., Ma, L., Zhou, S., & Liu, X. (2021). Mechanical properties and thermal characteristics of different-density phenolic foams. Journal of Thermal Analysis and Calorimetry, 144(2), 393-401.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...