Phenolic insulation board: operating temperature range, applications and advantages

2025-07-28 19:48:04

1. What is Phenolic Insulation Board?

Phenolic insulation board is a highly efficient thermal insulation material made from phenolic resin through a special manufacturing process. It is widely used in construction, cold chain logistics, and industrial applications due to its excellent thermal insulation, fire resistance, and high-temperature performance.

What sets phenolic insulation board apart is its combination of high thermal insulation properties and strong mechanical strength. It is especially suited for environments with extreme temperature fluctuations or specific temperature requirements. In this article, we will focus on the temperature range of phenolic insulation boards and explore their performance across different application scenarios.

2. Temperature Range of Phenolic Insulation Board: Revealing Extreme Performance

The temperature range of phenolic insulation board is one of its greatest advantages. Compared to traditional insulation materials, phenolic insulation board remains stable across a wider temperature spectrum, offering excellent performance even under extreme temperature conditions.Phenolic Insulation Board

Common Temperature Range

Phenolic insulation boards typically have a temperature range from -50°C to 120°C. Depending on the production process and resin formulation, some high-end phenolic insulation boards can even operate stably between -200°C and 200°C. This broad temperature range makes phenolic insulation board suitable for environments that experience significant temperature changes, especially in industrial applications that require long-term exposure to high or low temperatures.

High-Temperature Performance

Phenolic insulation boards perform exceptionally well in high-temperature environments due to their unique chemical composition. Under normal operating conditions, phenolic boards effectively resist heat transfer, minimizing energy loss. For applications involving high-heat equipment such as heat exchangers, boilers, and furnaces, phenolic insulation board is an ideal choice due to its outstanding high-temperature resistance.

Low-Temperature Performance

In addition to its high-temperature capabilities, phenolic insulation board also excels in low-temperature environments. Thanks to its microporous structure, phenolic insulation boards can significantly reduce heat flow in cold environments, maintaining stable internal temperatures. In applications like cold chain logistics, refrigeration systems, and cryogenic environments, phenolic insulation board's low-temperature performance is particularly advantageous.

3. Application Scenarios for Phenolic Insulation Board

The phenolic insulation board’s unique temperature tolerance makes it highly versatile across various environments, particularly those with extreme temperatures. Here are some typical application scenarios:

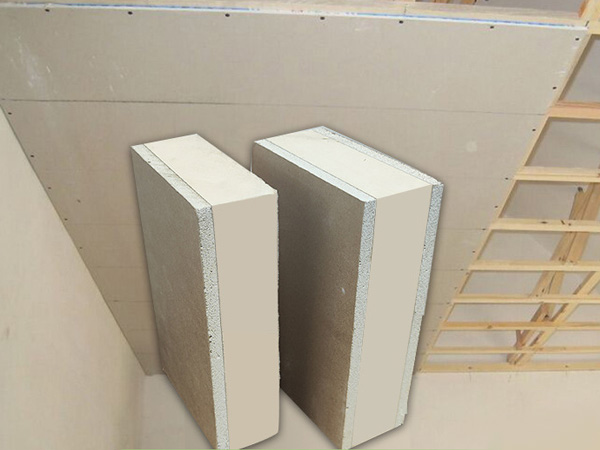

Construction Industry

In the construction industry, phenolic insulation boards are widely used for wall, roof, and floor insulation. They are particularly favored in projects requiring thermal insulation, soundproofing, and fire resistance. Due to its excellent high-temperature performance, phenolic insulation board ensures long-term safety and comfort in buildings.

Industrial Equipment Insulation

For industrial equipment like boilers, pipelines, generators, and hot water systems, phenolic insulation boards are not only able to withstand high-temperature working conditions but also protect against temperature-induced damage. In high-pressure, high-temperature conditions, phenolic insulation boards' stability and compressive strength make them a reliable choice for insulation.

Cold Chain Logistics

Cold chain transportation and storage require precise temperature control, and phenolic insulation boards are ideal for refrigeration equipment. From cold storage warehouses to refrigerated transport vehicles, phenolic insulation boards effectively block external temperature influences, helping to maintain product quality during transit and storage.

Energy Industry

In sectors like oil and gas exploration, chemical plants, and petroleum refineries, phenolic insulation boards are extensively used due to their high-temperature resistance. The fire-resistant properties of phenolic boards also help reduce the risk of fires, ensuring the safety of both facilities and personnel.

4. Why Choose Phenolic Insulation Board Over Traditional Materials?

Although there are many insulation materials on the market, phenolic insulation board has numerous unique advantages compared to traditional options like polyurethane (PU) and expanded polystyrene (EPS).

Higher Temperature Tolerance

As previously mentioned, phenolic insulation boards can handle a broader temperature range—from -50°C to 120°C, and even higher for some models—making them more reliable than traditional materials in extreme environments.

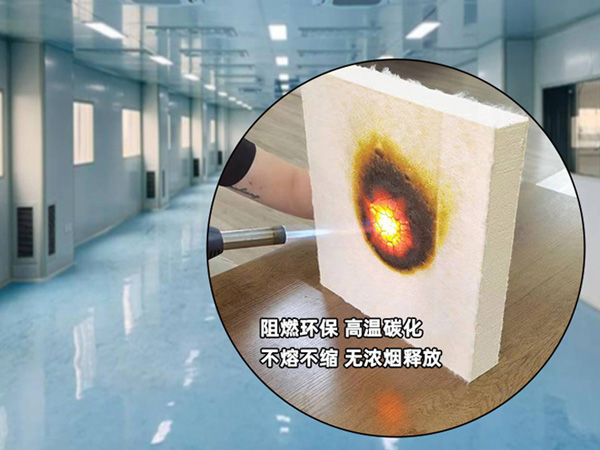

Superior Fire Resistance

Phenolic insulation boards offer exceptional fire resistance, maintaining high stability at elevated temperatures without releasing toxic gases. In contrast, traditional materials may melt or combust under high temperatures, posing greater safety risks.

Lower Thermal Conductivity

Phenolic insulation boards have a lower thermal conductivity, effectively reducing energy loss while enhancing thermal performance. This makes them more energy-efficient than traditional materials, particularly in commercial and residential buildings.

Better Environmental Adaptability

Whether in extreme heat or cold, phenolic insulation boards retain their insulation properties, while traditional materials may degrade or lose effectiveness in fluctuating conditions.

5. Conclusion: The Advantages of Choosing Phenolic Insulation Board and Future Trends

Phenolic insulation boards, with their superior temperature resistance, fireproof properties, and excellent thermal insulation performance, have become one of the most sought-after insulation materials. Whether used in the construction industry, industrial equipment, cold chain logistics, or the energy sector, phenolic insulation boards offer outstanding performance.

Compared to traditional insulation materials like polyurethane and expanded polystyrene, Phenolic Insulation Board excels in both temperature range and overall performance. Choosing phenolic insulation boards is not only a smart decision for improving insulation efficiency but also for ensuring long-term safety and energy savings.

As awareness of energy efficiency and environmental sustainability continues to grow, the future of phenolic insulation boards looks promising. Whether you are looking to improve energy efficiency, reduce fire hazards, or meet specific temperature-related requirements, Phenolic Insulation Board is the ideal choice for your next project.

By understanding the temperature range and diverse applications of phenolic insulation boards, you can make an informed decision when selecting the right insulation material for your needs. Choosing Phenolic Insulation Board ensures better performance, greater durability, and enhanced safety—outperforming traditional competitors in various extreme temperature environments.

References

GB/T 7714:Pektaş İ. High‐temperature degradation of reinforced phenolic insulator[J]. Journal of applied polymer science, 1998, 67(11): 1877-1883.

MLA:Pektaş, İlhami. High‐temperature degradation of reinforced phenolic insulator.Journal of applied polymer science 67.11 (1998): 1877-1883.

MLA:Pektaş, İ. (1998). High‐temperature degradation of reinforced phenolic insulator.Journal of applied polymer science,67(11), 1877-1883.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...