How Phenolic Foam Works as a High-Performance Insulation Material

2026-01-04 15:22:29

Phenolic Foam insulation has become an increasingly important material in modern building design, especially in projects focused on energy efficiency, fire safety, and long-term durability. Known for its low thermal conductivity and excellent fire performance, phenolic foam plays a vital role in high-performance insulation systems for residential, commercial, and industrial buildings.

This article explains how phenolic foam insulation works, what makes it different from other insulation materials, and why it is widely adopted in energy-conscious construction projects.

What Is Phenolic Foam Insulation?

Phenolic foam insulation is a rigid, closed-cell insulation material produced through the polymerization of phenolic resins. During production, a blowing agent creates a fine, uniform cell structure that traps air, significantly reducing heat transfer.

Thanks to controlled manufacturer-grade production processes, phenolic foam insulation achieves consistent density, thermal resistance, and dimensional stability, making it suitable for demanding insulation applications.

How Phenolic Foam Reduces Heat Transfer

The primary function of Phenolic Foam insulation is to minimize heat flow through building envelopes.

Low Thermal Conductivity

Phenolic foam features one of the lowest thermal conductivity values among conventional insulation materials. Its closed-cell structure limits both conductive and convective heat transfer.

Stable Cell Structure

The fine and uniform cell structure remains stable over time, maintaining insulation performance even under temperature fluctuations.

Reduced Thermal Bridging

When properly installed, phenolic foam insulation reduces thermal bridges in walls, roofs, and HVAC systems, improving overall energy efficiency.

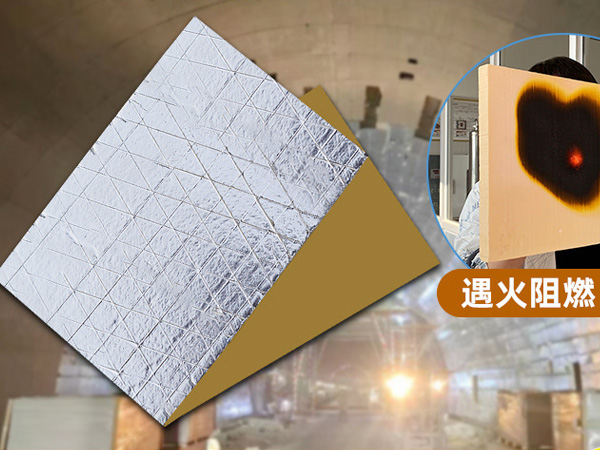

Fire Resistance and Safety Performance

One of the key advantages of phenolic foam insulation is its superior fire performance compared to many organic insulation materials.

Low Flame Spread

Phenolic foam chars rather than melts when exposed to fire, helping slow flame spread.

Reduced Smoke Generation

In fire conditions, phenolic foam produces significantly less smoke, improving occupant safety and visibility during evacuation.

These characteristics make phenolic foam insulation suitable for applications where fire safety regulations are strict.

Moisture Resistance and Dimensional Stability

Moisture control is essential for insulation effectiveness and building durability.

Low Water Absorption

The closed-cell nature of phenolic foam limits moisture penetration, reducing the risk of mold growth and thermal degradation.

Dimensional Stability

Phenolic foam maintains its shape and insulation performance under varying humidity and temperature conditions, which is crucial for long-term building performance.

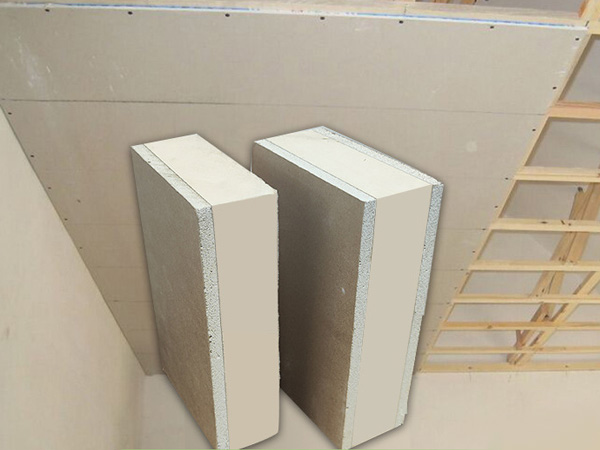

Applications of Phenolic Foam Insulation

Phenolic Foam insulation is used across a wide range of construction and industrial applications:

·External wall insulation systems

·Roof and ceiling insulation

·HVAC duct insulation

·Cold storage and industrial facilities

·Energy-efficient residential buildings

Its versatility allows designers to achieve high thermal performance without increasing wall or roof thickness.

Environmental and Energy-Saving Benefits

Phenolic foam insulation contributes to sustainable building practices in several ways.

Energy Efficiency

By reducing heat loss and gain, phenolic foam lowers heating and cooling demand, resulting in reduced energy consumption over the building’s lifecycle.

Long Service Life

Durable insulation materials reduce the need for replacement, minimizing material waste.

Compatibility with Green Building Standards

Phenolic foam insulation supports energy efficiency targets commonly required by modern building regulations.

Installation Considerations

Correct installation is essential to maximize the performance of phenolic foam insulation.

Key installation factors include:

·Proper sealing of joints to prevent air leakage

·Avoiding mechanical damage during installation

·Ensuring compatibility with adjacent building materials

Professional installation ensures consistent insulation performance throughout the building envelope.

Comparison with Other Insulation Materials

Compared to traditional insulation materials, phenolic foam insulation offers several advantages:

·Lower thermal conductivity than many mineral-based insulations

·Better fire performance than some plastic foams

·Higher insulation efficiency per unit thickness

These characteristics make phenolic foam an ideal choice for projects with limited space but high performance requirements.

Quality Control and Production Consistency

High-performance insulation relies on consistent material quality. Products manufactured under standardized production control systems and bulk supply capabilities ensure uniform performance across large-scale projects.

Consistency in density, thickness, and thermal resistance allows designers and contractors to meet strict project specifications with confidence.

Final Thoughts on Phenolic Foam Insulation

Phenolic Foam insulation is a high-performance material that supports modern energy-saving construction through excellent thermal efficiency, fire resistance, and durability. Its ability to deliver strong insulation performance in thinner profiles makes it particularly valuable in contemporary building design.

Backed by reliable manufacturing standards, controlled production methods, and dependable bulk supply capacity, phenolic foam insulation continues to play a critical role in creating safer, more energy-efficient buildings for the future.

References

GB/T 7714:Lee W E. 'Cellular solids, structure and properties'[J]. Materials Science and Technology, 2000, 16(2): 233.

MLA:Lee, W. E. "'Cellular solids, structure and properties'." Materials Science and Technology 16.2 (2000): 233.

APA:Lee, W. E. (2000). 'Cellular solids, structure and properties'. Materials Science and Technology, 16(2), 233.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...