Key Physical Properties of Phenolic Foam for Building Applications

2026-01-13 16:03:26

Understanding Phenolic Foam in Modern Construction

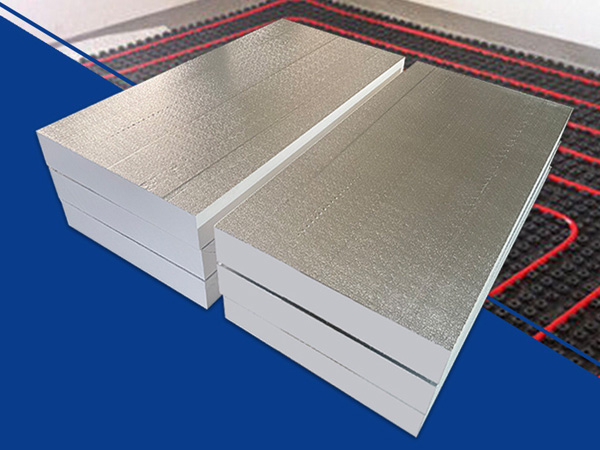

Phenolic Foam has become an increasingly important insulation material in contemporary building applications due to its excellent physical performance and fire safety characteristics. As energy efficiency standards rise worldwide, architects, engineers, and material manufacturers are paying closer attention to insulation materials that combine thermal efficiency, durability, and safety.

Used extensively in walls, roofs, HVAC systems, and industrial buildings, Phenolic Foam offers a balance of lightweight structure and high-performance insulation. For building projects that require stable quality and consistent specifications, Phenolic Foam produced through controlled industrial production processes provides a reliable solution for large-scale use.

1. Low Thermal Conductivity

One of the most important physical properties of Phenolic Foam is its exceptionally low thermal conductivity. This characteristic allows it to effectively reduce heat transfer through building envelopes, contributing to improved energy efficiency and reduced heating and cooling costs.

The closed-cell microstructure of Phenolic Foam traps air within fine, uniform pores, minimizing heat movement. Compared with many traditional insulation materials, Phenolic Foam can achieve the same insulation performance with a thinner profile, making it especially suitable for space-limited building designs.

This thermal efficiency is a key reason why Phenolic Foam is widely specified in both residential and commercial construction projects.

2. Excellent Fire Resistance Performance

Fire safety is a critical consideration in building material selection. Phenolic Foam is known for its inherent flame-retardant properties, which distinguish it from many organic insulation materials.

When exposed to high temperatures, Phenolic Foam tends to form a protective char layer rather than melting or dripping. This behavior helps slow flame spread and reduce smoke generation, contributing to safer evacuation conditions during a fire.

Due to these physical characteristics, Phenolic Foam is often used in applications where strict fire performance standards are required, such as high-rise buildings, public facilities, and industrial structures.

3. High Mechanical Strength and Dimensional Stability

Despite its lightweight nature, Phenolic Foam exhibits good mechanical strength, including compressive resistance and structural integrity. This allows it to maintain shape and performance under normal building loads and environmental stress.

Dimensional stability is another important physical property. Phenolic Foam resists deformation caused by temperature fluctuations or long-term use, helping insulation systems remain effective throughout the building’s service life.

For projects requiring consistent quality, Phenolic Foam supplied by experienced manufacturers through standardized production lines ensures stable physical performance across bulk orders.

4. Low Water Absorption and Moisture Resistance

Moisture control plays a vital role in building durability and indoor comfort. Phenolic Foam demonstrates relatively low water absorption due to its closed-cell structure, which limits moisture penetration.

By resisting water ingress, Phenolic Foam helps maintain its thermal performance even in humid environments. This property reduces the risk of mold growth and material degradation, contributing to healthier indoor spaces and longer-lasting insulation systems.

These characteristics make Phenolic Foam suitable for use in building envelopes, basements, and HVAC insulation where moisture exposure may occur.

5. Lightweight Structure and Easy Handling

Another key physical advantage of Phenolic Foam is its low density. The lightweight structure reduces transportation costs and simplifies on-site handling and installation.

From a construction efficiency perspective, lighter insulation materials help improve installation speed and reduce labor intensity. For large-scale projects requiring bulk supply, Phenolic Foam produced through continuous industrial manufacturing processes allows for consistent sizing, density control, and reliable delivery schedules.

6. Chemical Stability and Aging Resistance

Phenolic Foam shows good resistance to many chemicals commonly encountered in building environments. This chemical stability helps prevent degradation when exposed to air pollutants, construction materials, or minor chemical contact.

Additionally, Phenolic Foam demonstrates strong aging resistance, retaining its insulation and mechanical properties over long periods. This makes it suitable for long-term building applications where maintenance access may be limited.

7. Environmental and Energy Efficiency Benefits

While performance remains the primary focus, Phenolic Foam also contributes to sustainability goals in construction. Its high insulation efficiency supports reduced energy consumption over the building lifecycle.

By lowering heating and cooling demands, Phenolic Foam helps reduce overall carbon emissions associated with building operation. This aligns with modern green building standards and energy-efficiency regulations adopted in many regions.

Conclusion: Why Phenolic Foam Is a Reliable Building Insulation Material

Phenolic Foam stands out as a versatile and high-performance insulation material for modern building applications. Its key physical properties—including low thermal conductivity, fire resistance, mechanical strength, moisture resistance, and dimensional stability—make it well suited for a wide range of construction needs.

For projects requiring consistent quality, large-volume production, and dependable material performance, Phenolic Foam manufactured through controlled industrial processes provides a reliable solution. As building standards continue to evolve, Phenolic Foam remains a practical choice for manufacturers, contractors, and designers seeking efficiency, safety, and long-term value.

References

GB/T 7714:Al-Homoud M S. Performance characteristics and practical applications of common building thermal insulation materials[J]. Building and environment, 2005, 40(3): 353-366.

MLA:Al-Homoud, Mohammad S. "Performance characteristics and practical applications of common building thermal insulation materials." Building and environment 40.3 (2005): 353-366.

APA:Al-Homoud, M. S. (2005). Performance characteristics and practical applications of common building thermal insulation materials. Building and environment, 40(3), 353-366.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...