Phenolic Foam Board vs Traditional Insulation Materials

2026-01-10 16:01:32

As energy efficiency and fire safety become increasingly important in modern construction, insulation materials play a critical role in building performance. Among the many options available, Phenolic Foam Board has gained attention for its high thermal efficiency and advanced safety characteristics. To better understand its value, it is useful to compare phenolic foam board with traditional insulation materials commonly used in residential and commercial buildings.

This article provides a detailed comparison to help designers, builders, and homeowners make informed insulation choices.

Understanding Phenolic Foam Board

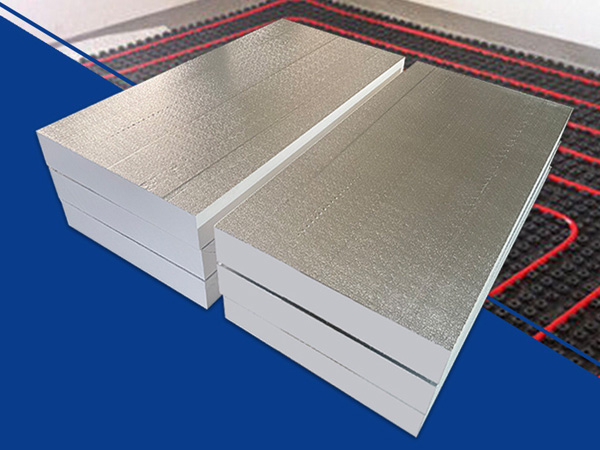

Phenolic Foam Board is a rigid insulation material produced through a controlled foaming process using phenolic resin. Its closed-cell structure allows it to deliver excellent thermal resistance while maintaining dimensional stability.

Modern phenolic foam boards are typically manufactured under standardized manufacturer-level production systems, ensuring consistent density, thickness, and performance across batches. This consistency makes them suitable for large-scale construction and energy-efficient building projects.

Overview of Traditional Insulation Materials

Traditional insulation materials have been used for decades and include several common types:

·Mineral wool

·Fiberglass insulation

·Expanded polystyrene (EPS)

·Extruded polystyrene (XPS)

Each of these materials has specific strengths and limitations in terms of insulation performance, fire resistance, moisture behavior, and longevity.

Thermal Performance Comparison

Thermal performance is often measured by thermal conductivity or R-value.

Phenolic Foam Board

Phenolic foam board offers very low thermal conductivity, meaning it provides high insulation performance with relatively thin panels. This allows architects to achieve energy targets without increasing wall thickness.

Traditional Insulation Materials

·Mineral wool and fiberglass generally require greater thickness to achieve similar insulation levels.

·EPS and XPS offer moderate thermal performance but typically fall short of phenolic foam in efficiency per unit thickness.

For projects where space efficiency and thermal performance are priorities, phenolic foam board has a clear advantage.

Fire Resistance and Safety

Fire performance is a key consideration in modern building regulations.

Phenolic Foam Board

One of the most notable benefits of Phenolic Foam Board is its excellent fire resistance. When exposed to flame, it produces low smoke and forms a char layer that helps slow fire spread.

Traditional Materials

·Mineral wool performs well in fire resistance but lacks high thermal efficiency.

·EPS and XPS are combustible and may require additional fire protection measures.

·Fiberglass resists flame but may lose structural integrity at high temperatures.

Overall, phenolic foam board offers a balanced combination of insulation efficiency and fire safety.

Moisture Resistance and Durability

Phenolic Foam Board

The closed-cell structure of phenolic foam board limits moisture absorption, helping maintain insulation performance over time. This makes it suitable for use in exterior wall systems, roofs, and areas exposed to temperature variations.

Traditional Insulation Materials

·Mineral wool can absorb moisture if not properly protected.

·Fiberglass may lose performance when wet.

·EPS and XPS resist water but can degrade under prolonged UV exposure.

Long-term durability is one reason phenolic foam board is increasingly chosen for high-performance building envelopes.

Installation and Design Flexibility

Phenolic Foam Board

Phenolic foam boards are rigid and lightweight, making them easy to cut and install. Their structural stability allows for precise fitting in wall and roof assemblies.

Traditional Materials

Flexible materials like fiberglass require careful handling to avoid gaps and compression. Rigid foams such as EPS and XPS are easier to install but may require thicker layers to meet performance targets.

From a design standpoint, phenolic foam board supports compact, efficient construction solutions.

Environmental and Energy-Saving Considerations

Reducing energy consumption is a primary goal of modern insulation systems.

·Phenolic Foam Board helps reduce heating and cooling loads due to its superior insulation properties.

·Thinner insulation layers mean less material usage and more usable interior space.

In large projects supported by organized production capacity and bulk supply, phenolic foam board contributes to consistent energy-saving performance across entire building developments.

Cost Considerations Over the Building Lifecycle

Initial material costs for phenolic foam board may be higher than some traditional insulation options. However, lifecycle costs often tell a different story.

·Improved thermal efficiency reduces long-term energy expenses.

·Enhanced fire safety can lower insurance and compliance costs.

·Durability minimizes maintenance and replacement needs.

When evaluated over the full lifespan of a building, phenolic foam board often delivers strong overall value.

Applications Where Phenolic Foam Board Excels

Phenolic foam board is commonly used in:

·Exterior wall insulation systems

·Roofing assemblies

·Curtain wall applications

·Energy-efficient residential buildings

·Commercial and industrial facilities

Its combination of performance characteristics makes it suitable for projects with strict energy and safety requirements.

Final Comparison Summary

When comparing Phenolic Foam Board with traditional insulation materials, several key differences emerge:

·Higher thermal efficiency per unit thickness

·Superior fire resistance with low smoke generation

·Strong moisture resistance and long-term stability

·Flexible application in modern building designs

Traditional insulation materials still have valid uses, but phenolic foam board offers a high-performance alternative for energy-conscious construction.

Conclusion: Choosing the Right Insulation Solution

Selecting the right insulation material depends on project goals, regulatory requirements, and long-term performance expectations. Phenolic Foam Board stands out as a modern insulation solution that balances thermal efficiency, safety, and durability.

Supported by advanced manufacturing processes, stable production systems, and reliable bulk supply capability, phenolic foam board continues to play an important role in the evolution of energy-efficient and safe building construction.

References

GB/T 7714:Asdrubali F, D'Alessandro F, Schiavoni S. A review of unconventional sustainable building insulation materials[J]. Sustainable Materials and Technologies, 2015, 4: 1-17.

MLA:Asdrubali, Francesco, Francesco D'Alessandro, and Samuele Schiavoni. "A review of unconventional sustainable building insulation materials." Sustainable Materials and Technologies 4 (2015): 1-17.

APA:Asdrubali, F., D'Alessandro, F., & Schiavoni, S. (2015). A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, 4, 1-17.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...