Phenolic Pipe Insulation Section: Durable Thermal Shielding for Oil and Gas Pipelines

2025-10-17 15:43:53

In the high-demand world of oil and gas operations, the stability and protection of pipeline systems are critical. Temperature changes, humidity, and chemical exposure can easily compromise pipeline performance if not properly managed. One material that consistently stands out for long-term insulation reliability is the Phenolic Pipe Insulation Section.

Built using advanced closed-cell foam technology, phenolic insulation combines low thermal conductivity, high fire resistance, and impressive moisture control—qualities that make it an ideal solution for pipelines exposed to harsh conditions. Many global projects now rely on phenolic pipe insulation manufacturers from China, who offer bulk supply and consistent technical quality for industrial applications.

1. What Is a Phenolic Pipe Insulation Section?

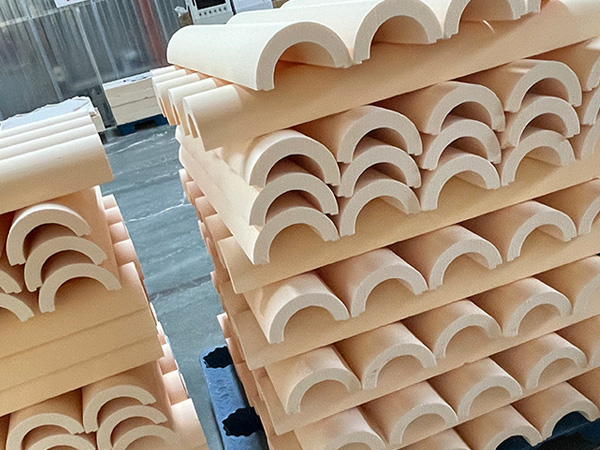

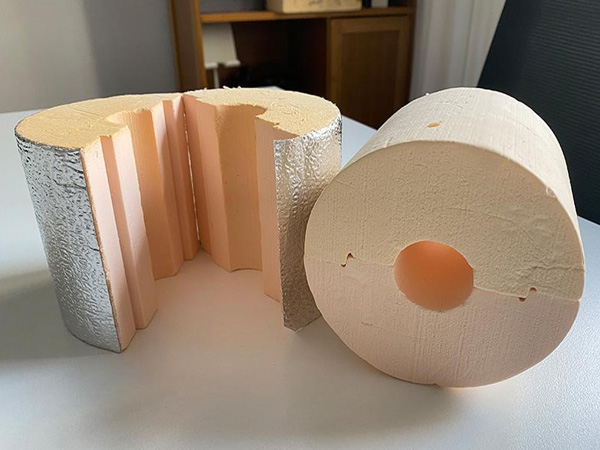

A Phenolic Pipe Insulation Section is a pre-formed rigid foam component made from phenolic resin. Through a foaming process, the resin develops a fine closed-cell structure that effectively traps air, minimizing heat transfer and preventing liquid absorption.

These semi-cylindrical sections are designed to wrap around pipelines of various diameters, providing a snug, continuous insulation layer. The rigid foam resists deformation and mechanical stress, maintaining both insulation integrity and shape under thermal expansion or vibration.

This unique material composition gives phenolic insulation an edge over traditional polyurethane or mineral wool, especially in industrial sectors where reliability and safety are top priorities.

2. The Importance of Insulation in Oil & Gas Pipelines

Pipeline systems in oil and gas infrastructure are subject to extreme thermal and environmental stress. They transport fluids at high or low temperatures through diverse climates—from icy tundras to desert heat. Without proper insulation, such pipelines would experience:

·Significant energy loss, raising operational costs.

·Condensation and corrosion, especially in cold-line systems.

·Safety hazards, due to excessively hot surfaces.

·Reduced service life, caused by material fatigue and corrosion under insulation (CUI).

By applying Phenolic Pipe Insulation Sections, engineers can effectively stabilize temperatures, prevent corrosion, and extend pipeline longevity—all while reducing overall maintenance costs.

3. Core Advantages of Phenolic Pipe Insulation Section

a. Low Thermal Conductivity

Phenolic foam’s microcellular structure results in extremely low thermal conductivity, typically ranging from 0.020 to 0.025 W/m·K.

This allows pipelines to maintain operational temperatures efficiently, reducing heat loss and optimizing energy usage.

b. Excellent Fire Resistance

Unlike many conventional insulation materials, Phenolic Pipe Insulation Section offers exceptional fire performance.

It exhibits low flame spread, minimal smoke output, and limited toxic gas emission—critical safety factors in oil and gas environments.

It meets international fire standards such as ASTM E84 and BS 476, ensuring safe use in refineries, LNG facilities, and offshore platforms.

c. Moisture and Corrosion Control

The closed-cell structure prevents water vapor from entering the insulation body, a key defense against corrosion under insulation (CUI).

This moisture resistance is particularly valuable for coastal or offshore pipelines where condensation and salt exposure are common threats.

d. Mechanical Strength with Lightweight Design

Phenolic insulation maintains high compressive strength while remaining lightweight.

It’s easy to handle, cut, and install, which shortens project timelines without sacrificing performance.

The material also resists mechanical vibration and temperature cycling, retaining its structure over years of operation.

e. Environmentally Safer and Economical

Modern phenolic foams are CFC-free and HCFC-free, minimizing environmental impact.

Their long lifespan and superior energy-saving properties make them not only sustainable but also cost-effective over the full pipeline lifecycle.

4. Real-World Applications

Phenolic Pipe Insulation Sections are used across a wide range of oil and gas operations, including:

·Pipeline networks carrying crude oil, natural gas, or chemicals.

·Refineries and petrochemical complexes.

·LNG and cryogenic plants, where extreme temperature control is essential.

·Offshore production units exposed to moisture and vibration.

·Power and utility lines requiring thermal stability and fire protection.

Their broad temperature tolerance—from –180°C up to +120°C—makes phenolic foam suitable for both hot and cold service lines.

5. Installation and Maintenance Recommendations

To achieve optimal durability and performance:

·Ensure pipe surfaces are clean, dry, and corrosion-free before insulation.

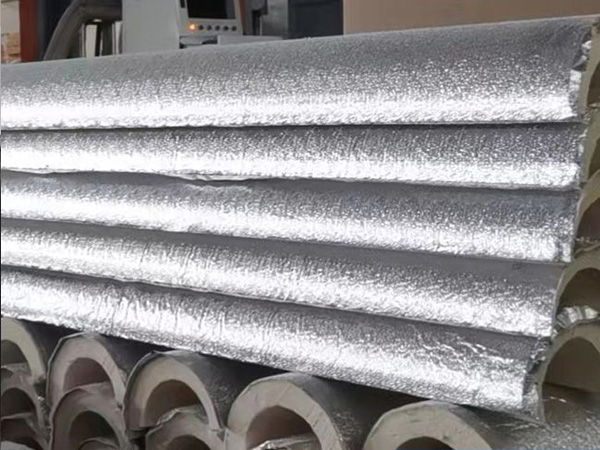

·Apply vapour barriers or protective jacketing (like aluminum or PVC) to block moisture intrusion.

·Seal all joints with compatible adhesive or mastic to maintain airtight integrity.

·Perform regular inspections to check for mechanical damage or external wear.

When properly installed and maintained, Phenolic Pipe Insulation Section can perform reliably for two decades or more, even under fluctuating temperatures and heavy field conditions.

6. Why Choose Chinese Manufacturers for Phenolic Pipe Insulation Sections

With decades of experience and strong production capability, China-based manufacturers have become global leaders in producing high-performance phenolic insulation.

Partnering with a Phenolic Pipe Insulation Section manufacturer in China ensures:

·Strict adherence to ASTM, ISO, and EN quality standards.

·Customized pipe diameters and insulation thicknesses for any project requirement.

·Stable bulk supply, ensuring timely delivery for large-scale projects.

·Competitive pricing supported by advanced manufacturing technology.

This combination of scalability, precision, and affordability makes Chinese suppliers a trusted choice for international oil and gas contractors seeking reliable insulation materials.

7. Conclusion: The Smart Choice for Pipeline Protection

When it comes to thermal insulation in demanding energy environments, the Phenolic Pipe Insulation Section stands apart for its balance of safety, strength, and sustainability.

Its remarkable resistance to heat, moisture, and fire ensures pipelines remain efficient, corrosion-free, and secure throughout their operational life.

Working with a China-based phenolic insulation manufacturer offering bulk supply capacity guarantees quality, availability, and excellent project value.

In a world where pipeline safety and efficiency are non-negotiable, Phenolic Pipe Insulation Section remains the dependable choice—engineered to perform, built to last.

References

GB/T 7714:Chen X, Yu W, Ma L, et al. Mechanical properties and thermal characteristics of different-density phenolic foams[J]. Journal of Thermal Analysis & Calorimetry, 2021, 144(2).

MLA:Chen, Xiaokun, et al. "Mechanical properties and thermal characteristics of different-density phenolic foams." Journal of Thermal Analysis & Calorimetry 144.2 (2021).

APA:Chen, X., Yu, W., Ma, L., Zhou, S., & Liu, X. (2021). Mechanical properties and thermal characteristics of different-density phenolic foams. Journal of Thermal Analysis & Calorimetry, 144(2).

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...