High-Temperature Resistance and Industrial Value of Phenolic Pipe Insulation Section

2025-10-20 16:54:26

The Role of Heat Resistance in Industrial Pipelines

In high-demand industrial systems, insulation is more than temperature control—it is protection for the entire operation. As industries strive for higher efficiency and sustainability, Phenolic Pipe Insulation Section has become one of the most reliable materials for maintaining performance under extreme heat.

Its combination of high-temperature resistance, low thermal conductivity, and fire safety makes it indispensable in power generation, oil and gas, and HVAC applications. Many China suppliers now specialize in providing bulk supply of phenolic insulation, meeting strict international standards and offering cost-effective manufacturing solutions for large-scale projects.

What Is Phenolic Pipe Insulation Section?

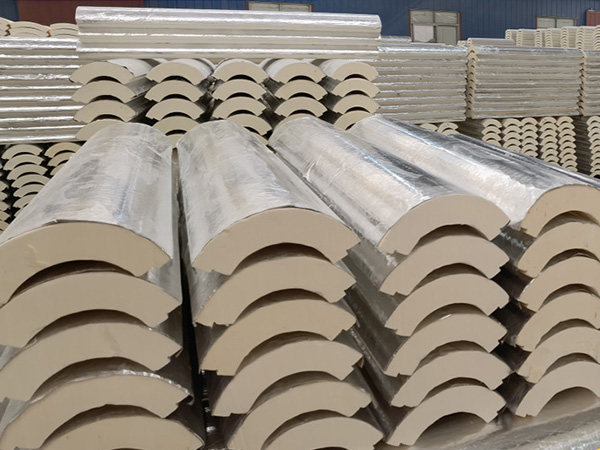

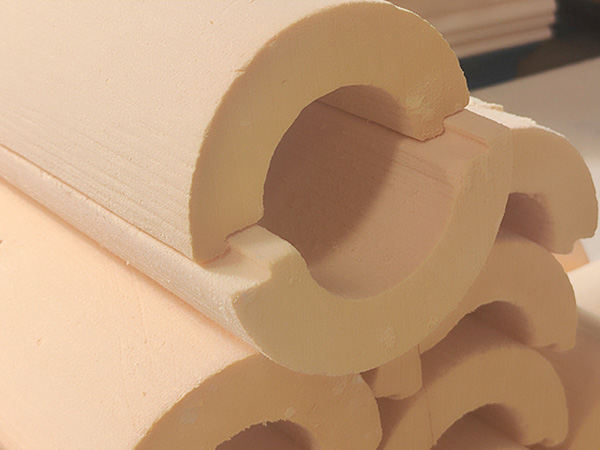

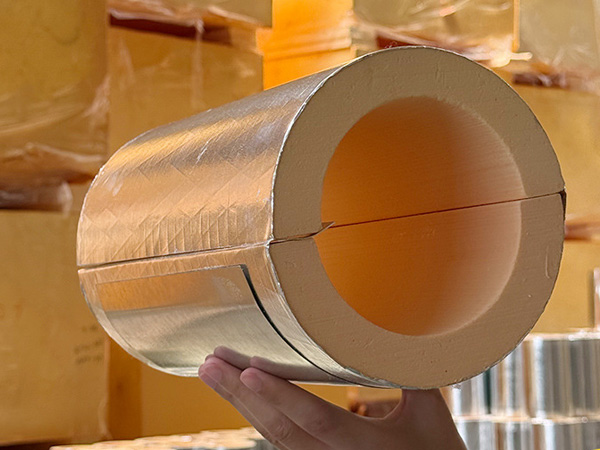

A Phenolic Pipe Insulation Section is a rigid pre-formed sleeve made from phenolic foam, a thermosetting resin material known for its fine closed-cell structure. This design traps air, minimizing heat transfer while maintaining mechanical strength.

Typical properties include low thermal conductivity (around 0.020–0.025 W/m·K), excellent flame retardancy, and resistance to water absorption. Unlike traditional insulation materials, phenolic foam remains stable over a wide temperature range—from cryogenic conditions up to around 180°C—making it suitable for both cold and hot pipeline applications.

Why Phenolic Insulation Excels at High Temperatures

The unique molecular structure of phenolic foam contributes directly to its thermal stability. Its tightly cross-linked network resists softening and deformation even under long-term heat exposure.

Instead of melting or dripping, the material gradually forms a char layer that protects the inner surface of the insulation. Tests conducted under ASTM C411 and ISO 1927 show that phenolic insulation retains its structure and insulation value even after repeated heating cycles.

This makes Phenolic Pipe Insulation Section ideal for applications such as steam lines, chemical process pipes, and thermal transfer systems where temperature fluctuations are constant.

International Standards and Quality Control

High-quality Phenolic Pipe Insulation Sections produced by China manufacturers meet or exceed recognized global standards. These include:

·ASTM C518, which measures thermal conductivity.

·ASTM E84, assessing surface flame spread and smoke generation.

·EN 14314, specifying requirements for rigid phenolic foam in building and industrial use.

·ISO 9001 and ISO 14001, ensuring product consistency and environmental management.

Through rigorous testing—covering density, compressive strength, and long-term heat exposure—China’s phenolic insulation producers can provide bulk supply that maintains consistent quality for international markets.

Key Industrial Applications

The adaptability of Phenolic Pipe Insulation Section allows it to be applied across many sectors.

In power plants, it serves as an essential insulator for high-pressure steam lines and feedwater systems.

In petrochemical industries, it protects process pipes and reduces energy loss in refineries.

In HVAC systems, phenolic insulation is used to minimize heat gain in chilled water and air distribution systems.

It is also widely used in marine, food, and chemical industries, where temperature control and safety are critical.

Its ability to perform reliably in both high-heat and humid environments has made it a global choice for energy-efficient pipeline insulation.

Advantages Over Traditional Materials

Phenolic insulation offers a combination of benefits not commonly found in other materials.

It provides lower heat transfer rates than polyurethane or mineral wool, ensuring better energy retention.

Its rigid form gives it superior shape stability, preventing sagging or deformation over time.

Additionally, phenolic foam resists moisture absorption, reducing the risk of corrosion beneath the insulation.

Another critical advantage is fire safety. Unlike many organic materials, phenolic foam has a naturally high fire resistance and produces minimal smoke, making it compliant with strict building and industrial fire codes.

Strength of China Suppliers and Manufacturers

The reliability of China suppliers in the phenolic insulation market is built on technological advancement and production capacity.

Most established China manufacturers now operate automated foaming and molding lines, allowing precise density control and uniformity.

This enables them to handle bulk orders efficiently while maintaining the required thermal and structural performance standards.

Their ability to customize pipe diameters, thicknesses, and coating materials provides flexibility for a wide range of industrial applications.

At the same time, large-scale production keeps pricing competitive, allowing international buyers to balance performance with project budgets.

Maintenance and Longevity

Although Phenolic Pipe Insulation Section is durable, proper maintenance ensures its long-term efficiency.

Inspecting joints, resealing seams, and replacing damaged outer cladding can prevent heat leaks and maintain optimal insulation performance.

Regular monitoring for mechanical wear or UV exposure (especially in outdoor installations) also extends service life.

With correct installation and care, phenolic insulation can last over two decades without significant performance degradation, even in harsh industrial settings.

Energy Efficiency and Sustainability

Phenolic foam’s high insulation efficiency helps industries significantly reduce heat loss, saving up to 40% in energy consumption compared with uninsulated pipelines.

It also contributes to sustainability goals—its low smoke emission, minimal water absorption, and recyclable properties make it an eco-friendly option for modern infrastructure projects.

As more industries shift toward green energy and carbon reduction, the demand for sustainable insulation materials like Phenolic Pipe Insulation Section continues to grow.

Conclusion

The Phenolic Pipe Insulation Section combines thermal stability, fire safety, and mechanical strength to deliver long-lasting performance in demanding environments.

Its ability to withstand high temperatures without deformation makes it the preferred choice for power generation, chemical, and HVAC systems worldwide.

Backed by advanced China suppliers and China manufacturers with proven bulk supply capacity, this insulation solution provides exceptional value for industrial users seeking both reliability and efficiency.

Investing in high-quality phenolic insulation isn’t just a technical decision—it’s a commitment to safer, more energy-efficient, and sustainable operations for years to come.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...