Enhancing Fire Safety Standards with Phenolic Insulation Board

2025-10-24 16:52:40

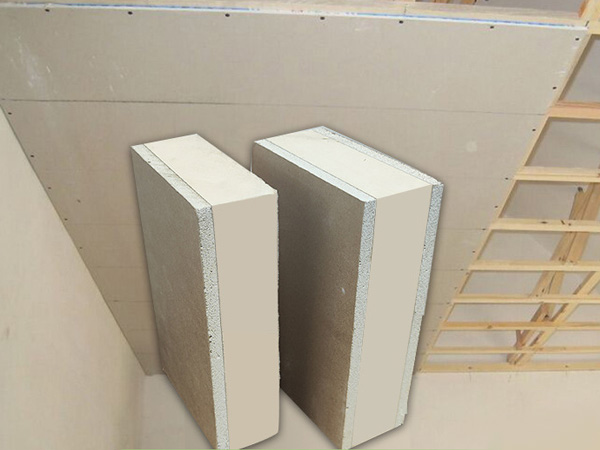

In the construction industry, fire safety has become one of the most critical performance indicators for modern buildings. As global regulations tighten and safety requirements evolve, architects, engineers, and contractors are turning to materials that not only insulate effectively but also resist fire hazards. Among the available options, the Phenolic Insulation Board stands out as a premium choice for achieving both goals—superior insulation and high-level fire protection.

With strong technical development and bulk supply from experienced China manufacturers, this insulation solution is redefining how buildings meet international fire standards while maintaining cost efficiency and sustainability.

Rising Fire Safety Demands in Modern Construction

Recent fire incidents worldwide have led to stricter building codes, especially in high-rise and public structures. Insulation materials, often hidden within walls and ceilings, play a vital role in controlling flame spread and smoke development.

While traditional foams such as polyurethane (PU) and polystyrene (EPS) may offer good insulation, they tend to release toxic gases when burned. By contrast, the Phenolic Insulation Board remains dimensionally stable under heat, produces very low smoke, and prevents the flame from spreading—features that make it one of the safest materials in its category.

As more China factory suppliers adopt ISO and EN fire testing protocols, phenolic insulation boards are now widely trusted for use in commercial buildings, transportation hubs, and energy facilities.

Why Phenolic Insulation Board Excels in Fire Resistance

The fire-resistant performance of Phenolic Insulation Board is the result of its unique cellular structure and the chemical nature of phenolic resin. When exposed to flame, it undergoes carbonization, forming a dense char layer that acts as a thermal barrier and slows down heat transfer.

Unlike other foams, phenolic insulation does not melt or drip, and once the heat source is removed, it tends to self-extinguish. Moreover, it emits very low smoke and negligible toxic gases, ensuring safety during evacuation.

Tests under EN 13501-1, BS 476, and ASTM E84 consistently classify phenolic insulation as a Class A or Class 0 material, confirming its suitability for structures with strict fire safety requirements.

Key Benefits Beyond Fire Resistance

Apart from exceptional fire performance, Phenolic Insulation Board provides a number of advantages that enhance its overall value in construction projects:

·Low Thermal Conductivity: Offers outstanding energy efficiency with typical values around 0.020–0.024 W/m·K.

·Lightweight but Strong: Reduces structural load and simplifies installation.

·Moisture and Chemical Resistance: Prevents degradation in humid or industrial environments.

·Eco-Friendly Composition: Free from CFCs, HCFCs, and low in formaldehyde emission.

·Long Service Life: Retains mechanical and thermal properties for decades.

Bulk supply from China insulation board factories ensures consistent density, uniform cell structure, and cost advantages for large-scale developments.

Practical Applications in Fire-Safe Construction

Phenolic insulation boards are now used across multiple building types and industrial environments:

·Building Facades: Serve as a fire barrier layer behind cladding systems.

·Roofs and Ceilings: Maintain insulation without compromising flame resistance.

·HVAC Ducts: Prevent the spread of fire through ventilation channels.

·Pipelines and Industrial Equipment: Offer both heat retention and fire protection.

Many China suppliers provide tailored phenolic insulation boards and pipe sections in bulk quantities, customized in thickness, facing material, and fire rating to meet specific project needs.

By working directly with these factories, project managers can ensure on-time delivery, certified quality, and full compliance with international standards.

Cost Considerations and Procurement Insights

Although Phenolic Insulation Board typically has a higher initial cost compared to conventional foam insulations, its long-term performance offsets the difference. The product’s ability to reduce heat loss, lower energy bills, and minimize fire risk translates into significant lifecycle savings.

Collaborating directly with China factory suppliers enables construction companies to access bulk supply at competitive prices while maintaining full quality control. The availability of in-house testing reports, ISO certification, and customizable dimensions adds further reliability for engineering teams seeking project-specific solutions.

Towards a Safer and More Sustainable Future

With sustainability becoming as important as safety, Phenolic Insulation Board is gaining popularity in green building certifications such as LEED and BREEAM. Manufacturers in China are integrating low-emission curing processes and recyclable raw materials to further enhance the environmental profile of phenolic products.

As construction technology evolves, this insulation solution will continue to serve as a foundation for fire-safe and energy-efficient architecture, bridging the gap between modern safety expectations and environmental responsibility.

Conclusion

Improving fire safety in buildings requires materials that go beyond compliance—materials that actively contribute to protection, comfort, and sustainability. The Phenolic Insulation Board achieves precisely that. It combines outstanding fire resistance, excellent thermal efficiency, and long-term durability in a single engineered product.

Supported by China manufacturers with proven bulk supply capacity, this insulation material represents a smart, reliable choice for architects and builders seeking high performance without compromise.

Whether used in facades, HVAC ducts, or industrial pipelines, Phenolic Insulation Board is helping redefine global fire safety standards—one project at a time.

References

GB/T 7714:Hidalgo J P, Torero J L, Welch S. Fire performance of charring closed‐cell polymeric insulation materials: Polyisocyanurate and phenolic foam[J]. Fire and Materials, 2018, 42(4): 358-373.

MLA:Hidalgo, Juan P., José L. Torero, and Stephen Welch. "Fire performance of charring closed‐cell polymeric insulation materials: Polyisocyanurate and phenolic foam." Fire and Materials 42.4 (2018): 358-373.

APA:Hidalgo, J. P., Torero, J. L., & Welch, S. (2018). Fire performance of charring closed‐cell polymeric insulation materials: Polyisocyanurate and phenolic foam. Fire and Materials, 42(4), 358-373.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...