The Environmental Impact of Phenolic Insulation Board Production

2025-10-25 18:59:23

As sustainability becomes a defining element of modern construction, the environmental footprint of insulation materials is under closer scrutiny.

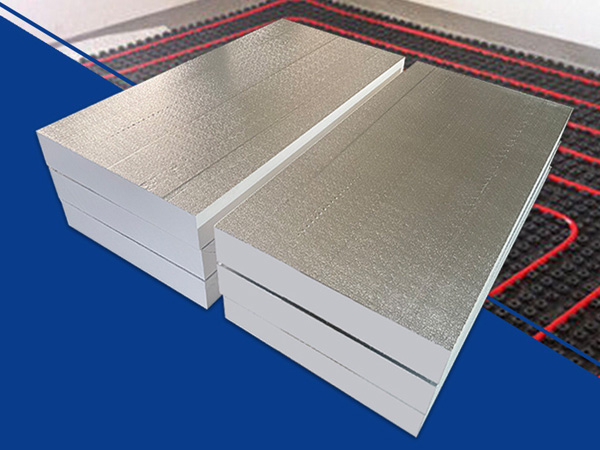

Among numerous options, the Phenolic Insulation Board has gained attention for combining superior fire performance, low thermal conductivity, and long service life.

Today, many China manufacturers are reforming production lines to lower carbon emissions and energy use—demonstrating that bulk supply can still align with eco-conscious goals. Understanding how phenolic boards are made and how they impact the planet provides valuable insight for project planners and green architects.

1. Understanding the Production Process

The Phenolic Insulation Board is formed through a polymer reaction of phenol and formaldehyde resins, producing a rigid foam with a fine, closed-cell structure.

During production, the resin mixture expands and solidifies into panels that deliver excellent insulation and fire resistance.

However, this chemical process can release volatile compounds if unmanaged. Modern China factory suppliers now employ sealed systems and advanced ventilation to capture emissions, recycle residual materials, and recover excess heat—significantly reducing the environmental burden.

2. Environmental Strengths of Phenolic Insulation Boards

Although it’s a synthetic product, Phenolic Insulation Board offers distinct ecological advantages:

·High Thermal Efficiency: With a thermal conductivity around 0.020–0.024 W/m·K, phenolic boards cut building energy use drastically.

·Extended Lifespan: Their long service life reduces replacement frequency and material waste.

·Low Toxic Emission: Unlike some foam plastics, phenolic insulation emits minimal smoke and toxic gases during fire events.

·Improved Fire Safety: Its inherent resistance to flame spread limits both environmental and structural damage in emergencies.

These factors make phenolic boards a key material in low-carbon construction and energy-efficient architecture.

3. Environmental Challenges During Manufacturing

Despite its many benefits, Phenolic Insulation Board production presents several sustainability challenges that manufacturers are working to overcome.

a. Raw Material Dependency

Traditional phenolic resin is derived from petrochemical sources. Extracting and refining these raw materials consumes energy and contributes to CO₂ emissions.

To mitigate this, several China suppliers are introducing bio-based phenol alternatives, helping to reduce fossil resource reliance.

b. Blowing Agent Selection

Earlier foaming agents used in insulation production were environmentally harmful. Now, manufacturers rely on HFOs (Hydrofluoroolefins) or pentane-based systems, which have negligible ozone depletion potential.

c. Energy Use in Production

The curing and drying stages are energy-intensive. To counter this, leading Chinese factories have incorporated solar-assisted curing, energy recovery systems, and optimized batch cycles to save up to 25% of total energy consumption.

d. Waste Management

Scraps and offcuts are increasingly being recycled into composite boards or repurposed as fillers, minimizing landfill waste and improving material utilization efficiency.

4. Life Cycle Analysis: Beyond the Factory Gate

From raw materials to end-of-life, Phenolic Insulation Boards demonstrate a balanced environmental profile when assessed through a Life Cycle Assessment (LCA) approach.

·Material Extraction Phase: Roughly 40% of the total embodied carbon originates here.

·Production Phase: Efficient technologies can cut factory emissions by 20–30%.

·Use Phase: Energy savings achieved through reduced HVAC loads typically offset production emissions within a few years.

·Disposal Phase: Emerging recycling and recovery techniques are improving sustainability outcomes at end-of-life.

Overall, Phenolic Insulation Board maintains a lower life-cycle carbon footprint than polyurethane or polystyrene insulation while providing comparable or superior insulation and fire resistance.

5. Green Manufacturing Practices in China

As environmental regulations tighten, China-based phenolic insulation manufacturers are integrating sustainability principles throughout the production chain:

·Renewable Raw Materials: Incorporating bio-based phenolic resins and eco-friendly additives.

·Emission Reduction: Installing VOC purification systems and closed-loop production lines.

·Resource Recycling: Reusing foam waste and by-products in new production cycles.

·Transparency: Providing customers with EPD (Environmental Product Declaration) reports for export and compliance purposes.

Such practices ensure consistent quality, large-scale bulk supply, and environmental accountability—solidifying China’s reputation as a global source of high-quality insulation solutions.

6. The Role of Phenolic Insulation Board in Green Construction

Phenolic boards are increasingly central to energy-efficient and low-emission building designs. Their thin profile and excellent R-value per thickness support compact wall structures while maintaining high thermal performance.

Architects and developers now rely on Phenolic Insulation Board for passive houses, hospitals, industrial facilities, and public infrastructure projects seeking LEED or BREEAM certification.

When sourced from China factory suppliers, buyers benefit from consistent bulk availability, reliable delivery, and sustainable production—all crucial for modern large-scale projects.

7. Future Directions in Sustainable Phenolic Insulation

The next generation of Phenolic Insulation Boards will focus on deeper environmental integration:

·Carbon-Neutral Production Plants powered by renewable energy.

·Closed-Loop Recycling systems for both factory waste and post-use materials.

·Water-Based Formulations to minimize chemical discharge.

·Digital Manufacturing that ensures precise foam density and zero-waste cutting.

These innovations demonstrate the industry’s transition from traditional foam manufacturing toward circular, low-emission production ecosystems.

Conclusion

The evolution of the Phenolic Insulation Board industry marks a significant step toward sustainable construction. From responsible sourcing to energy-efficient performance, the material offers both ecological and functional benefits.

With modern China manufacturers driving greener production and offering bulk supply to international markets, the Phenolic Insulation Board continues to set a benchmark for insulation products that combine environmental responsibility, safety, and long-term durability.

As the world shifts toward carbon-conscious building standards, this innovative material stands as proof that performance and sustainability can truly go hand in hand.

References

GB/T 7714:Mougel C, Garnier T, Cassagnau P, et al. Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution[J]. Polymer, 2019, 164: 86-117.

MLA:Mougel, C., et al. "Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution." Polymer 164 (2019): 86-117.

APA:Mougel, C., Garnier, T., Cassagnau, P., & Sintes-Zydowicz, N. (2019). Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution. Polymer, 164, 86-117.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...