Preventing Thermal Bridging with Phenolic Insulation Board

2025-12-17 12:14:28

As building performance standards continue to rise, the demand for insulation systems that can effectively block unwanted heat transfer has become critical. One of the leading materials in this effort is the Phenolic Insulation Board, known for its exceptionally low thermal conductivity and stable long-term performance. Preventing thermal bridging—areas where heat naturally flows through more conductive building elements—is essential for keeping buildings energy efficient, comfortable, and structurally healthy.

Whether used in new construction or retrofit projects, phenolic insulation offers a reliable way to create a continuous envelope with fewer weak spots. For builders, architects, and suppliers operating with manufacturer-level capacity or bulk production needs, understanding the strengths of phenolic boards is key to delivering consistent and predictable energy performance.

1. What Causes Thermal Bridging?

Thermal bridging happens when heat bypasses insulated sections of a building by traveling through materials with higher conductivity. These bridges often form at:

·Structural framing such as studs or joists

·Metal connectors and wall penetrations

·Balcony slabs or roof transitions

·Window and door interfaces

·Fasteners and attachment points

Even if a wall cavity is fully insulated, the presence of these conductive paths can significantly reduce overall thermal performance. Heat moves more rapidly through the bridge than through the insulation, causing cold spots, higher heating and cooling expenses, and potential condensation.

A Phenolic Insulation Board, when used as an uninterrupted outer layer, reduces these effects by covering surfaces that otherwise allow energy leakage.

2. Why Phenolic Insulation Board Works So Well

Phenolic insulation boards are manufactured from a fine closed-cell structure that naturally resists heat flow. Their unique chemistry and structure give them an advantage in thermal bridging prevention compared with many traditional insulation solutions.

2.1 High Thermal Efficiency in a Thin Profile

One of the standout traits of phenolic insulation is its very low thermal conductivity. This allows high R-values with less material thickness, making it easier to design slimmer walls while maintaining excellent performance. This compact efficiency is useful in projects where space and weight must be carefully managed.

2.2 Strong Dimensional and Mechanical Stability

Because phenolic boards retain their shape over time, they deliver consistent insulation with no sagging or compression. A stable panel ensures full contact with adjacent layers and limits the development of air gaps—common points where thermal bridges start to form.

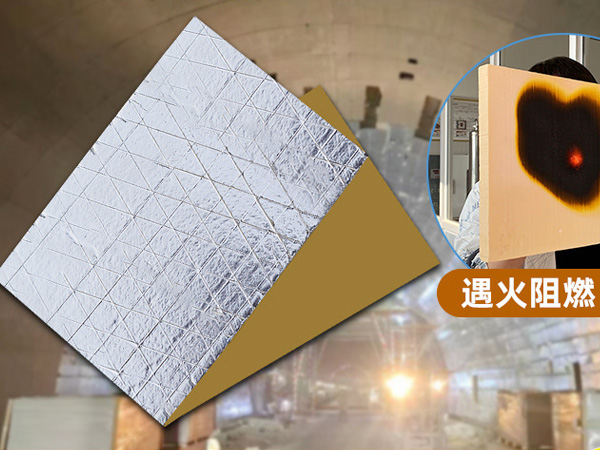

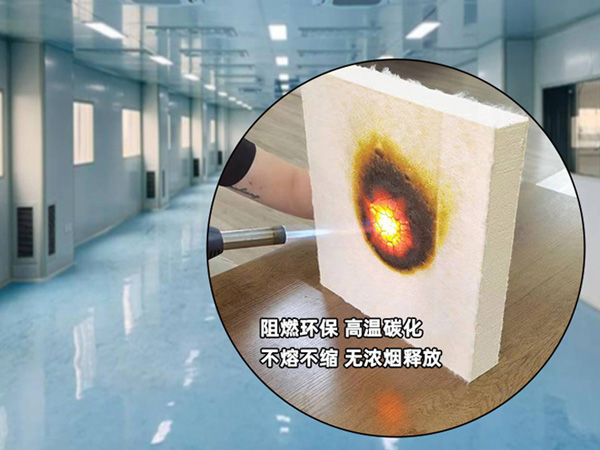

2.3 Resistance to Moisture and Fire

Phenolic materials resist moisture uptake, meaning their insulation value does not degrade easily in humid environments. Additionally, they exhibit strong fire-performance characteristics, an important factor for exterior insulation systems and commercial building assemblies.

2.4 Ideal for Bulk Supply and Manufacturer-Level Use

Their uniform density and consistency make phenolic boards suitable for high-volume fabrication. Manufacturers appreciate their compatibility with automated cutting and large-scale production workflows.

3. Where Phenolic Boards Make the Biggest Impact

Because of their versatility and high performance, phenolic insulation boards are widely used in several key building areas where thermal bridging must be controlled.

3.1 External Wall Assemblies

When installed continuously over sheathing or structural framing, phenolic boards act as a thermal blanket that blocks conductive paths created by studs, screws, and joints. This reduces cold spots and maintains a more consistent interior temperature.

3.2 Roofing Systems

Roof assemblies—particularly warm roofs—often benefit from phenolic insulation due to the material’s ability to resist thermal drift and maintain efficiency under varying temperatures. A continuous layer above the deck reduces bridging at rafters and mechanical fasteners.

3.3 Floor Edges and Perimeter Foundations

Slab edges are notorious for heat loss because they connect interior spaces directly with the ground or exterior conditions. Phenolic insulation helps create a protective thermal buffer around these edges.

3.4 Openings and Transition Points

Areas around windows, doors, and façade connections require precise insulation to avoid thermal interruptions. Phenolic boards can be cut and fitted tightly in these spaces, reinforcing the building’s envelope.

4. Strategies for Effective Installation

Proper installation is essential for maximizing the thermal performance of phenolic insulation boards and limiting bridges.

4.1 Maintain Continuity Across All Surfaces

Insulation should be laid in a way that minimizes breaks. Overlapping joints, careful alignment, and tight edge connections ensure heat cannot bypass the system.

4.2 Use Compatible Sealants and Tapes

Board-to-board gaps must be sealed to prevent air infiltration. Approved tapes and sealants help maintain a continuous thermal and air barrier.

4.3 Protect the Insulation from Exposure

Although phenolic boards are stable, they still require appropriate cladding or protective coatings when used externally to shield them from weather.

4.4 Combine with Proper Air and Vapor Control

A high-performance insulation system depends on effective moisture and air management. Phenolic insulation pairs well with vapor barriers and air-tight membranes when installed according to envelope design guidelines.

5. Benefits for Large Projects and Bulk Production

Phenolic insulation boards are increasingly used in large residential and commercial developments due to their consistency, handling ease, and compatibility with automated systems. Suppliers offering bulk production benefit from:

·Predictable material behavior

·Reduced waste during cutting and installation

·Lightweight panels that simplify logistics

·High performance over long service life

These factors make phenolic boards a preferred choice for scalable, manufacturer-level building applications.

Conclusion

Preventing thermal bridging is essential for achieving energy-efficient and durable building envelopes. A Phenolic Insulation Board provides one of the most reliable methods for creating continuous insulation layers that block conductive heat flow across walls, roofs, and structural intersections. With excellent thermal resistance, long-term stability, and reliable moisture and fire performance, phenolic insulation is a powerful tool in modern building design.

For contractors, builders, and suppliers working with manufacturer standards or bulk production demands, phenolic boards offer consistent quality and high thermal performance. When applied correctly, they form a seamless protective layer that enhances comfort, reduces energy consumption, and strengthens the long-term resilience of the structure.

Choosing high-performance Phenolic Insulation Board remains one of the most effective ways to eliminate thermal bridging and achieve superior envelope efficiency in today’s construction world.

References

GB/T 7714:Kośny J, Kossecka E. Multi-dimensional heat transfer through complex building envelope assemblies in hourly energy simulation programs[J]. Energy and Buildings, 2002, 34(5): 445-454.

MLA:Kośny, Jan, and Elizabeth Kossecka. "Multi-dimensional heat transfer through complex building envelope assemblies in hourly energy simulation programs." Energy and Buildings 34.5 (2002): 445-454.

APA:Kośny, J., & Kossecka, E. (2002). Multi-dimensional heat transfer through complex building envelope assemblies in hourly energy simulation programs. Energy and Buildings, 34(5), 445-454.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...