Manufacturing Process of Phenolic Insulation Pipe Sections

2025-06-19 09:04:51

Manufacturing Process of Phenolic Insulation Pipe Sections

1. Raw Material Preparation

Resin Formulation:

Phenolic resin (resole type) is synthesized from phenol and formaldehyde under alkaline conditions, with a controlled molar ratio (1:1.5 to 1:2.5).

Additive Mixing:

Blowing agents (e.g., pentane), surfactants, and flame retardants (e.g., aluminum trihydrate) are added to the resin.

2. Foaming & Curing

Pre-Form Mixing:

The resin mixture is injected into a high-shear mixer with acid catalysts (e.g., sulfuric acid) to initiate polymerization.

Expansion:

The exothermic reaction generates gas, expanding the foam into molds at 70–90°C for 5–15 minutes.

Post-Curing:

Pipe sections are heat-treated at 120–150°C for 2–4 hours to complete crosslinking and remove residual volatiles.

3. Machining & Shaping

CNC Cutting:

Cured blocks are precision-cut into half-cylindrical pipe sections using diamond-tipped saws.

Surface Finishing:

Inner/outer surfaces are sanded to achieve smoothness (Ra <25μm) for proper sealing.

4. Quality Control

Density Verification: Core samples tested per ASTM C303 (target range: 45–80 kg/m³).

Fire Testing: Validated via ISO 11925-2 (flammability) and EN 13823 (SBI).

Thermal Conductivity: Measured using guarded hot plate (ISO 8301) at 10°C intervals.

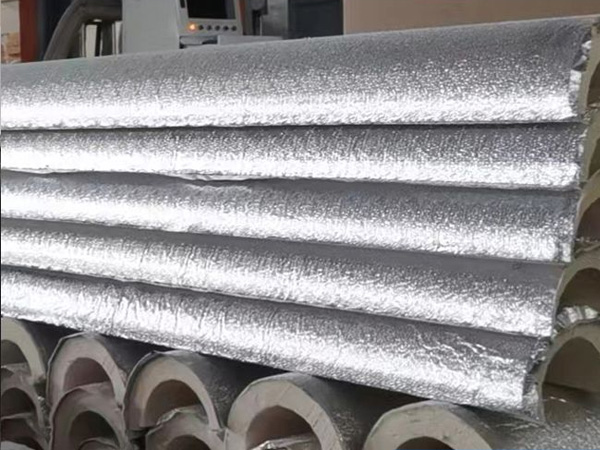

5. Packaging & Storage

Moisture Protection: Vacuum-sealed in polyethylene with desiccant packs.

Stacking Protocol: Maximum 5 layers with interleaving boards to prevent deformation.

Advanced Variations:

Aerogel-Enhanced: For cryogenic service (-196°C), silica aerogel is infused (λ=0.017 W/m·K).

Fiber-Reinforced: Fiberglass mesh embedded for high-pressure steam pipes (16 bar rating).

Note: Modern plants recover >95% of formaldehyde emissions via scrubbers, complying with EPA Tier IV standards.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...