Precision Selection Guide for Phenolic Insulation Pipe Sections

2025-06-19 09:05:58

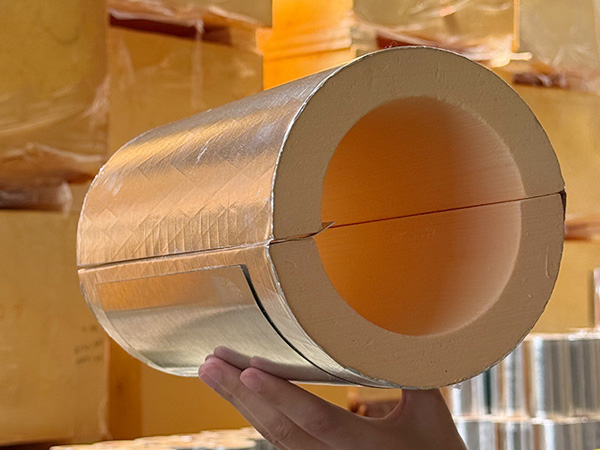

Precision Selection Guide for Phenolic Insulation Pipe Sections

1. Temperature Range Verification

Cryogenic Service (-196°C to -50°C):

Specify ultra-low-density foam (45–55 kg/m³) with fiberglass reinforcement to prevent brittle fracture.

High-Temperature Pipes (95°C–150°C):

Choose high-crosslink-density formulations with ceramic microspheres (tested per ASTM C411 for 1,000-hour stability).

2. Mechanical Load Assessment

Compression Requirements:

For walkable areas or buried pipes, select ≥80 kg/m³ density (250+ kPa strength per ASTM C165).

Vibration Zones:

Opt for elastomer-modified phenolic with 15% EPDM content (damping loss factor >0.05 at 50Hz).

3. Chemical Compatibility

Oil/Gas Pipelines:

Acid-cured phenolic resists hydrocarbons (pH 2–12 compatibility per NACE TM0177).

Chilled Water Systems:

Closed-cell structure (water absorption <1.5%) with antimicrobial additives for wet environments.

4. Fire Safety Compliance

Building Codes:

Euroclass B-s1,d0 (EN 13501-1) for commercial buildings.

Industrial Standards:

IMO FTP Code Part 5 for marine, API 2218 for oil refineries.

5. Installation Constraints

Tight Spaces:

Pre-cut 45°/90° elbows with self-sealing butyl laps.

Outdoor Exposure:

UV-resistant foil facings or protective jacketing (PVC/SS 316).

6. Sustainability Factors

Low-GWP Formulations:

Pentane-blown foam (GWP=7) vs. traditional HCFC-141b (GWP=725).

End-of-Life Recyclability:

Select binder-free grades for pyrolysis recovery (70% material reuse).

Pro Tip: For steam pipes >125°C, combine with aerogel blankets in a hybrid system—reduces thickness by 40% while maintaining R-value.

Validation Protocol:

Request 3rd-party test reports (ASTM C177, ISO 4589).

Conduct mock-up installations on 10m pipe sections.

Perform IR thermography after 30 thermal cycles.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...