Common Issues During Installation of Phenolic Insulation Pipe Sections

2025-06-19 09:09:08

Common Issues During Installation of Phenolic Insulation Pipe Sections

1. Poor Adhesion to Substrate

Root Causes:

Oily/dirty pipe surfaces (oil residues, rust scales)

Improper adhesive selection (mismatched with pipe material)

Low ambient temperature (<5°C) delaying curing

Solutions:

Clean pipes with acetone and steel brushes

Use epoxy-based adhesives for metals, polyurethane for plastics

Apply heating blankets in cold environments

2. Joint Sealing Failures

Critical Problems:

Gaps >3mm at longitudinal seams causing thermal bridges

Butyl tape peeling off within 6 months

Preventive Measures:

Install with 20mm overlap at joints

Use two-part polysulfide sealants for high-vibration areas

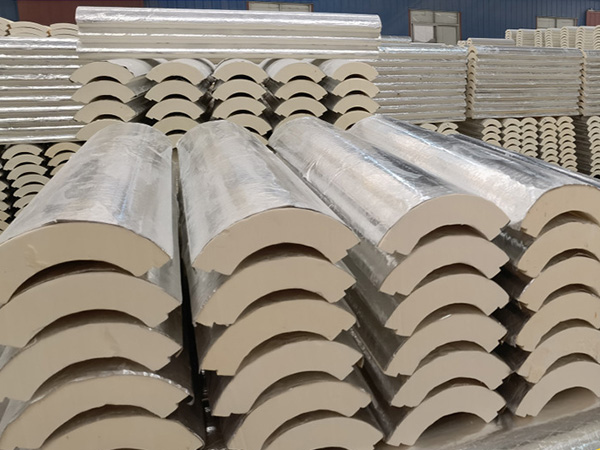

3. Mechanical Damage During Handling

Vulnerability Points:

Edge chipping during transport (especially at thickness >50mm)

Surface dents from tool impacts

Protection Methods:

Reinforce edges with fiberglass mesh during manufacturing

Use nylon lifting straps instead of metal hooks

4. Thermal Expansion Mismatch

Observed Issues:

Buckling at fixed supports due to restricted movement

Adhesive failure at temperature cycling zones

Engineering Controls:

Allow 5mm expansion gap per meter at anchors

Specify flexible adhesives with ≥50% elongation

5. Condensation at Penetrations

Problem Areas:

Pipe hangers creating cold bridges

Uninsulated valve flanges

Best Practices:

Install insulated PVC spacer rings at supports

Pre-fabricate removable insulation boxes for valves

6. Firestop Integration Challenges

Compliance Gaps:

Incomplete filling of annular spaces

Incompatible fireproofing materials

Certified Solutions:

Use intumescent putty pads (UL 1479 listed)

Conduct smoke penetration tests (ASTM E814)

Pro Tip: For projects with >500 linear meters, conduct trial installations on 10m test sections to verify:

Adhesive cure time

Thermal performance via IR camera

Firestop integration

Emergency Repair Protocol:

For damaged sections in service:

Isolate area and dry surfaces

Apply rapid-cure epoxy putty

Wrap with stainless steel banding

Re-test thermal performance within 24h

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...