Waterproof and Moisture Resistance Mechanism of Phenolic Insulation Pipe Sections

2025-06-19 09:08:08

Waterproof and Moisture Resistance Mechanism of Phenolic Insulation Pipe Sections

1. Closed-Cell Structure Barrier

The phenolic foam's tightly packed, non-interconnected cellular architecture (cell size 100-300μm) physically blocks liquid water penetration. Independent testing shows water absorption rates below 1.5% by volume even after 28-day immersion (per ASTM C272).

2. Hydrophobic Chemical Composition

Phenolic resin's benzene ring structure creates inherent water repellency, with a contact angle exceeding 90°. Advanced formulations incorporate silicone-based modifiers to boost this effect, achieving contact angles up to 120° (superhydrophobic range).

3. Vapor Diffusion Resistance

The material's low permeability rating of 0.8-1.2 perm-inch (ASTM E96) outperforms most organic foams. This results from:

Narrow cell window diameters (<5μm)

Residual resin crosslinking that obstructs molecular pathways

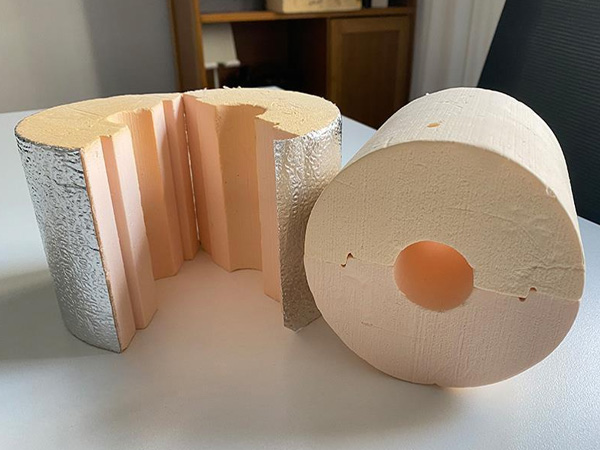

4. Integrated Protective Layers

Manufacturing processes often include:

In-situ laminated aluminum foil facings (≥7μm thickness)

Polymer-coated glass fiber reinforcements

These provide additional moisture barriers while maintaining flexibility at joints.

5. Self-Sealing Installation Features

Pre-applied butyl adhesive strips at longitudinal seams create continuous watertight seals during installation. Testing demonstrates these maintain integrity through 500+ thermal cycles from -20°C to 80°C.

6. Long-Term Performance Safeguards

pH-balanced formulations (5.5-7.5) prevent acidic degradation in humid environments

Non-hygroscopic additives minimize capillary action at cut edges

Biocidal agents inhibit mold growth at relative humidity up to 95%

Critical Application Note: For underground or submerged service, specify phenolic pipes with:

Hot-melt extruded polyethylene jacketing

Welded seam verification (ISO 13968)

Cathodic protection compatibility testing

Maintenance Advantage: Unlike fibrous insulations, water exposure doesn't permanently degrade R-value - after drying, phenolic recovers >98% of original thermal performance (per ISO 11561).

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...