Application of Phenolic Insulation Pipe Sections in Medical Gas Pipelines

2025-06-19 09:16:37

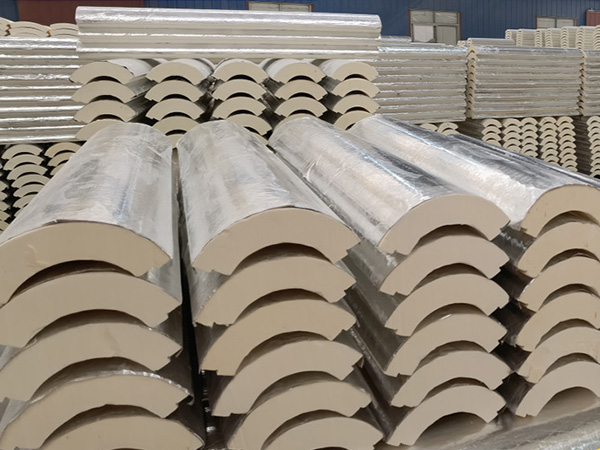

Application of Phenolic Insulation Pipe Sections in Medical Gas Pipelines

1. Critical Performance Requirements

Thermal Stability: Maintains consistent insulation between 2–50°C, ensuring stable gas temperatures for oxygen, nitrous oxide, and vacuum systems.

Fire Safety: Meets NFPA 99 standards with:

Flame spread index ≤25 (ASTM E84)

Non-toxic fume emission (ISO 18562 biocompatibility)

Hygiene Compliance:

Smooth, non-porous surface prevents microbial growth (ISO 14698 cleanroom standards)

Withstands hospital-grade disinfectants (hydrogen peroxide, quaternary ammonium)

2. Installation Advantages

Precision Prefabrication:

Factory-cut elbows and tees ensure airtight joints, critical for maintaining 5.2±0.2 bar oxygen line pressures.

Space Efficiency:

30% thinner than mineral wool at equivalent R-value, enabling compact routing in ceiling voids.

Vibration Damping:

Reduces noise transmission from compressors by 15–20 dB(A).

3. Specialized Medical Applications

MRI Suite Pipelines:

Non-magnetic grades prevent interference with imaging equipment.

Pharmaceutical Grade Nitrogen:

Low outgassing formulations (<0.1% VOC) protect gas purity.

Cryogenic Medical Gas Storage:

Cryo-grade phenolic (λ=0.018 W/m·K at -150°C) for liquid oxygen backup systems.

4. Maintenance & Safety Protocols

Leak Prevention:

Butyl tape-sealed joints tested to 10,000 pressure cycles at 8 bar.

Sterilization Compatibility:

Withstands 134°C autoclaving for reprocessable components.

Emergency Repairs:

Pre-approved patch kits allow FDA-compliant field fixes without system shutdown.

5. Emerging Innovations

Antimicrobial Copper Coatings:

Lab-tested to reduce MRSA contamination by 99% (ISO 22196).

Smart Insulation:

RFID-tagged sections enable digital twin monitoring of insulation integrity.

Compliance Note: All installations must be validated per HTM 02-01 (UK) or ASHE 2018 (US) healthcare engineering standards. For neonatal units, specify formaldehyde-free formulations with third-party indoor air quality certifications.

Pro Tip: In hybrid med-gas/fire suppression systems, use dual-rated phenolic meeting both NFPA 99 and NFPA 13 requirements.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...