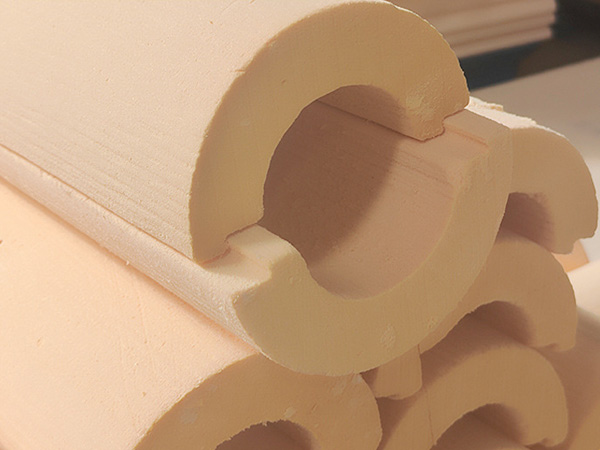

Maintenance Strategies to Extend Service Life of Phenolic Insulation Pipe Sections

2025-06-19 09:15:29

Maintenance Strategies to Extend Service Life of Phenolic Insulation Pipe Sections

1. Routine Inspection Protocol

Quarterly Visual Checks

Examine for surface cracks, joint separations, or moisture stains, focusing on elbows, valves, and supports.

Annual Infrared Thermography

Detect hidden moisture intrusion or insulation gaps (≥2°C temperature differential indicates defects).

2. Moisture Management

Seam Integrity Maintenance

Reapply elastomeric sealant (e.g., polysulfide) to aging joints every 3–5 years.

Drainage Verification

Clear weep holes in outdoor installations to prevent water pooling.

3. Mechanical Protection

Impact Zones

Install removable HDPE shields in areas prone to tool drops or foot traffic.

UV-Exposed Areas

Renew aluminum foil or acrylic coatings every 5–7 years in sunny climates.

4. Adhesive System Care

Edge Bond Reinforcement

Inject polyurethane adhesive beneath partially detached sections using syringe applicators.

Curing Conditions

For repairs below 5°C, use cold-cure adhesives with 72-hour curing blankets.

5. Chemical Exposure Control

Acid/Alkali Spills

Rinse immediately with pH-neutral cleaners; avoid abrasive scrubbing.

Oil/Grease Contamination

Degrease with citrus-based solvents to prevent resin degradation.

6. Structural Load Monitoring

Compression Recovery

Rotate pipe supports periodically to prevent permanent indentations.

Expansion Gap Maintenance

Ensure 5mm clearance at anchors to accommodate thermal movement.

7. Documentation & Analysis

Lifecycle Logging

Record installation dates, repair history, and thermal performance tests.

Failure Mode Tracking

Use microscopy (SEM) to analyze aged samples for resin cracking patterns.

Proactive Measures:

Preventive Replacements: Schedule partial renewals at 60% of expected service life (typically 15 years for industrial settings).

Training Programs: Educate maintenance staff on proper handling to avoid accidental damage.

Emerging Solutions:

Self-Healing Coatings: Microencapsulated resins automatically repair <3mm cracks.

IoT Sensors: Embedded moisture/temperature monitors provide real-time alerts.

Critical Reminder: Always follow OEM guidelines for adhesive/sealant compatibility to avoid material conflicts. For nuclear or offshore applications, implement ASME Section XI inspection protocols.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...