Common Issues and Solutions for Phenolic Foam Boards in Fire Protection Applications

2025-06-08 20:24:00

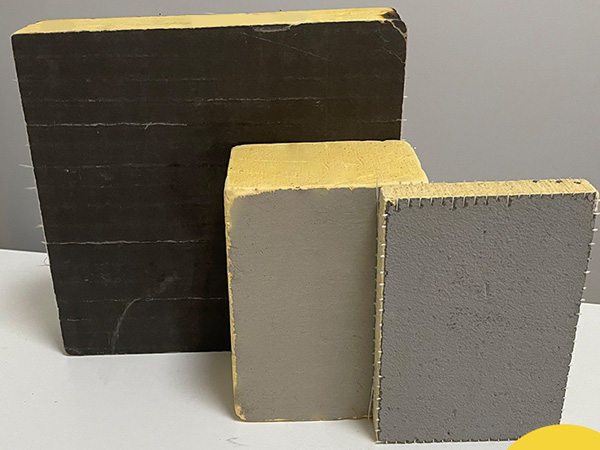

Common Issues & Solutions for Phenolic Foam Boards in Fire Protection Applications

1. Fire Rating Misunderstanding

Issue: Confusion between different fire classifications (e.g., EN 13501 vs. ASTM E84).

Solution: Clearly specify:

Euroclass A1/A2-s1,d0 (non-combustible)

ASTM E84 Class A (≤25 flame spread, ≤50 smoke)

Provide third-party test reports for verification.

2. Joint & Penetration Weak Points

Issue: Unsealed gaps or improper detailing at joints, pipes, and electrical penetrations compromise fire resistance.

Solution:

Use fire-rated sealants/mortars (tested to match board rating).

Install intumescent strips at movement joints.

Follow manufacturer’s compartmentation details.

3. Mechanical Damage During/After Installation

Issue: Cuts, abrasions, or fastener over-tightening reduce fire performance.

Solution:

Protective facings (e.g., aluminum foil, fiberglass).

Avoid exposed edges in high-risk areas.

Use fire-rated fasteners with thermal pads.

4. Adhesive Selection Errors

Issue: Standard adhesives may degrade under high heat.

Solution:

Fire-rated adhesives (e.g., cementitious or intumescent types).

Verify compatibility with phenolic foam (avoid solvent-based products).

5. Thermal Thickness Reduction

Issue: Thinner boards may not meet required fire resistance duration (e.g., 60/90/120 mins).

Solution:

Validate system thickness via fire testing (e.g., BS 476, EN 1364).

Consider multi-layer systems for extended protection.

6. Moisture & Fire Performance

Issue: Water ingress can reduce fire resistance over time.

Solution:

Closed-cell structure minimizes absorption.

Vapor barriers in humid environments (e.g., swimming pools).

7. Misapplication in High-Temperature Areas

Issue: Exceeding max service temp (~150°C continuous).

Solution:

Alternative materials (e.g., ceramic fiber) for >150°C.

Thermal gap design near heat sources.

8. Certification & Compliance Gaps

Issue: Local fire codes may require specific approvals.

Solution:

Provide system-level fire test reports (not just material ratings).

Confirm compliance with IBC, NFPA, Eurocodes.

Key Fire Protection Best Practices

✔ System Approach: Fire performance depends on full assembly (board + adhesive + finishes).

✔ Third-Party Testing: Request project-specific fire resistance test data.

✔ Installation Training: Ensure crews understand fire-stopping details.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...