Phenolic Insulation Boards in Roofing Applications: Common Issues and Solutions

2025-06-08 20:25:18

Phenolic Insulation Boards in Roofing Applications: Common Issues and Solutions

Phenolic insulation boards (PF boards) are widely used in roofing systems due to their excellent thermal performance, fire resistance, and moisture resistance. However, improper application can lead to performance issues. Below are common problems and solutions for phenolic boards in roof insulation.

1. Thermal Bridging and Condensation Risk

Issue:

Heat loss at joints, fasteners, and structural penetrations.

Condensation forming on cold surfaces, leading to moisture damage.

Solutions:

✅ Continuous insulation layer – Minimize gaps between boards.

✅ Thermal break fasteners – Use plastic or insulated metal fasteners.

✅ Vapor control layer – Install on the warm side (interior in cold climates).

✅ Proper joint sealing – Use compatible tape or liquid-applied sealant.

2. Mechanical Damage During Installation

Issue:

Boards may crack or dent if mishandled.

Foot traffic or dropped tools can damage the surface.

Solutions:

✅ Use protective walk boards during installation.

✅ Avoid excessive point loads (e.g., stacking heavy materials).

✅ Store flat and dry before installation.

3. Adhesion and Wind Uplift Resistance

Issue:

Poor adhesive bonding leads to delamination in high-wind areas.

Mechanical fasteners may not provide sufficient uplift resistance.

Solutions:

✅ Use high-strength polyurethane adhesives (full-spread or ribbon application).

✅ Follow fastener spacing guidelines (typically 300–400mm along edges).

✅ Ballasted roofs – Use gravel or pavers for added weight.

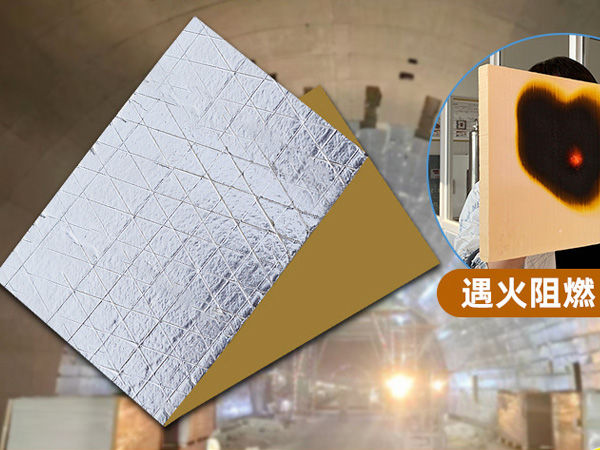

4. Fire Performance in Roof Assemblies

Issue:

Some roofing membranes may require additional fire protection.

Joints and penetrations can create weak points.

Solutions:

✅ Select fire-rated phenolic boards (Euroclass A1/A2 or ASTM E84 Class A).

✅ Use fire-resistant cover boards (e.g., fiber cement, gypsum).

✅ Seal penetrations with intumescent firestop materials.

5. Moisture and Water Absorption

Issue:

Standing water or leaks can degrade insulation over time.

Improper flashing leads to moisture ingress.

Solutions:

✅ Sloped roof design (minimum 2% slope for drainage).

✅ Closed-cell phenolic foam (low water absorption).

✅ Proper flashing at roof edges, penetrations, and drains.

6. Thermal Movement and Expansion Gaps

Issue:

Temperature fluctuations cause expansion/contraction, leading to buckling.

Solutions:

✅ Leave 3–5mm expansion gaps between boards.

✅ Use flexible sealants at joints.

✅ Avoid rigid adhesives that restrict movement.

7. Compatibility with Roofing Membranes

Issue:

Some membranes (e.g., PVC, TPO) may require separation layers.

Solutions:

✅ Use a separation layer (e.g., fiberglass mat) if needed.

✅ Consult membrane manufacturer for compatibility.

Best Practices for Roofing Applications

✔ Pre-installation inspection – Ensure substrate is clean, dry, and level.

✔ Follow manufacturer’s guidelines for adhesive, fasteners, and joint treatment.

✔ Quality control checks – Verify fastener pull-out strength and adhesive coverage.

✔ Protect insulation with a cover board or membrane immediately after installation.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...