Guidelines for Adhesive Selection in Phenolic Insulation Board Installation

2025-06-08 20:26:27

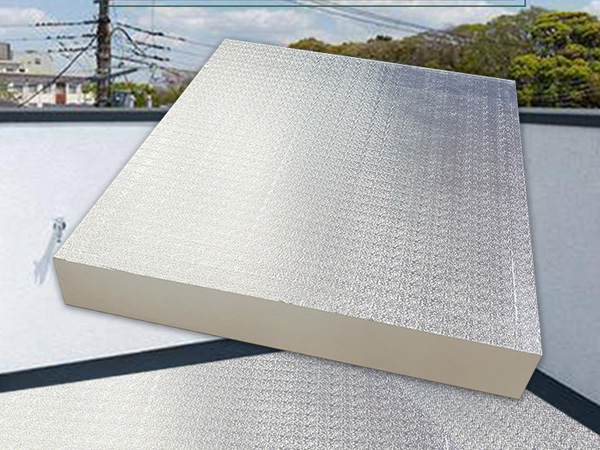

Guidelines for Adhesive Selection in Phenolic Insulation Board Installation

Proper adhesive selection is critical for ensuring the bonding strength, durability, and fire performance of phenolic (PF) insulation systems. Below are professional recommendations for adhesive use in phenolic board applications.

Key Requirements for Adhesives

✅ Compatibility

Must be chemically compatible with phenolic foam (avoid solvent-based adhesives that may dissolve the foam).

Recommended: Polyurethane (PU)-based or MS Polymer-modified adhesives.

✅ Bonding Strength

Minimum tensile bond strength: ≥0.1 MPa (EN 13499 standard).

Must adhere well to substrates (concrete, metal, wood, etc.).

✅ Weather Resistance

Withstands temperature fluctuations (-30°C to +80°C).

UV-resistant (for temporary exposed conditions).

✅ Fire Performance

For fire-rated applications, use Class A fire-resistant adhesives (e.g., cementitious or intumescent types).

✅ Environmental Safety

Low VOC emissions (compliant with GREENGUARD Gold or GB 50325 standards).

Critical Installation Guidelines

Substrate Preparation

Remove oil, dust, and loose particles.

Apply a primer on porous substrates (e.g., concrete, masonry).

Adhesive Application

Full-bed method: Apply adhesive to ≥40% of the board surface.

Peripheral bead method: Continuous adhesive strips along edges + intermittent dots in the field.

Avoid "butterfly" application (reduces bond strength).

Curing & Protection

Allow 24–48 hours curing (PU adhesives) before mechanical fastening.

Protect from rain/UV exposure during curing.

Fire-Rated Systems

Use tested adhesive/board combinations for fire compartmentation.

Ensure joints are sealed with fireproof tape/mortar.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...