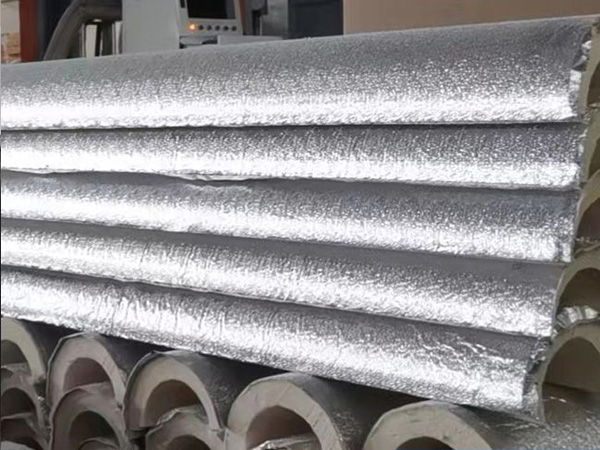

Fireproof and Corrosion-resistant Phenolic Pipe Shell for Chemical Pipelines

Engineered for aggressive chemical environments, our Fireproof & Corrosion-Resistant Phenolic Pipe Shell provides unmatched protection for industrial pipelines handling acids, alkalis, and solvents. Combining military-grade chemical resistance with Class A fireproof performance, this specialized insulation system ensures operational safety and energy efficiency in petrochemical plants, pharmaceutical facilities, and industrial processing units.

Core Performance Features

1. Extreme Chemical Resistance

Fully inert phenolic core resists:

• Concentrated acids (H2SO4, HCl, HNO3)

• Caustic solutions (NaOH, KOH)

• Organic solvents (acetone, ethanol)

Optional PTFE/FEP laminated facings for additional chemical barrier

2. Certified Fire Protection

Class A1 fire rating (EN 13501-1)

Zero flame spread with smoke density <5% (ASTM E662)

900°C integrity rating for 120+ minutes

3. Thermal & Mechanical Stability

0.023 W/m·K thermal conductivity maintained in chemical vapor environments

200kPa compressive strength withstands industrial impacts

-196°C to +180°C operational range (cryogenic to high-temp processes)

Technical Specifications

Density: 60-70kg/m³ (reinforced grade)

Thickness: 30-150mm (customizable)

Facings: SS316/PTFE/ceramic fiber (select based on chemical exposure)

Joint System: Chemical-resistant mastic sealed

Installation Advantages

✓ Pre-fabricated segments for pumps, valves, and flanges

✓ Explosion-proof static control versions available

✓ 50% faster installation than acid-proof wrapping systems

Complies with:

• ASME C1763 (chemical plant insulation)

• NACE SP0198 (CUI prevention)

• ISO 23993 (fire performance)

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05