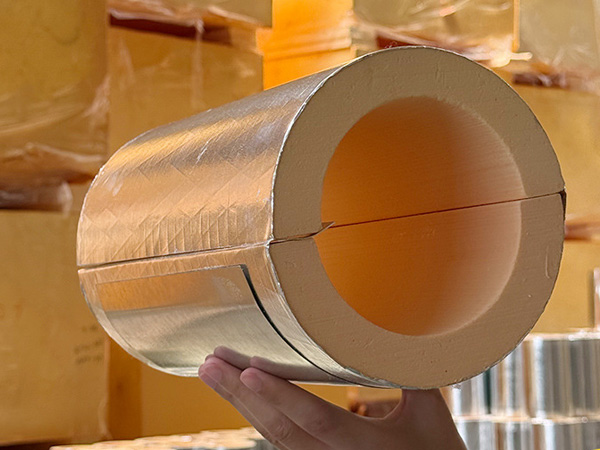

Phenolic Insulation Pipe Shell

The Phenolic Insulation Pipe Shell is a high-performance thermal solution designed for industrial, commercial, and HVAC piping systems. Made from rigid phenolic foam, it provides superior insulation efficiency, fire resistance, and long-term durability while ensuring a perfect fit for pipes of various diameters and configurations.

Key Features

1. Superior Thermal Performance

Ultra-low thermal conductivity (0.020–0.025 W/m·K) – Minimizes heat loss in heating systems and prevents condensation in cooling applications.

Stable insulation efficiency – Maintains performance even under extreme temperature fluctuations.

2. Fire-Resistant & Safe

Self-extinguishing properties – Does not support flame spread.

Low smoke emission – Enhances safety in enclosed spaces.

3. Moisture & Corrosion Resistance

Closed-cell structure – Prevents water absorption, eliminating corrosion under insulation (CUI).

Chemical resistance – Withstands exposure to oils, mild acids, and alkalis.

4. Custom-Made Precision Fit

Pre-fabricated shells – Designed for exact pipe diameters, including bends, valves, and flanges.

Split or multi-piece design – Easy installation and removal for maintenance.

5. Lightweight & Durable

50% lighter than traditional mineral wool or fiberglass wraps.

High compressive strength – Resists mechanical damage and maintains shape over time.

6. Easy Installation & Maintenance

Snap-on or adhesive installation – No specialized tools required.

Reusable – Can be removed and reinstalled without performance loss.

Applications

✔ HVAC Systems – Chilled water, steam, and condensate lines.

✔ Industrial Piping – Oil & gas, chemical plants, power stations.

✔ Marine & Offshore – Engine rooms, cryogenic pipelines.

✔ District Heating & Plumbing – Energy-efficient hot water distribution.

Advantages Over Traditional Insulation

30% higher thermal efficiency than fiberglass or rubber foam.

Longer lifespan – Resists sagging, moisture damage, and thermal degradation.

Cleaner installation – No loose fibers or messy wraps.

Space-saving – Thinner profile than mineral wool for the same R-value.

Installation Guide

Measure pipes – Provide exact outer diameter and configuration.

Select shell type – Choose thickness (20–100mm) and facing (foil, PVC, or stainless steel).

Secure in place – Use high-temperature adhesive or mechanical fasteners.

Seal joints – Apply foil tape or mastic for airtight insulation.

Why Choose Phenolic Pipe Shells?

Energy savings – Reduces heat loss by up to 30%, lowering operational costs.

Condensation control – Maintains surface temperature above dew point.

Labor efficiency – Cuts installation time by 50% compared to manual wrapping.

Conclusion

For pipelines requiring maximum thermal protection, fire safety, and durability, our Phenolic Insulation Pipe Shells deliver unmatched performance. Whether for retrofit or new installations, they ensure energy efficiency, reduced maintenance, and long-term reliability.

Contact us for custom solutions tailored to your piping specifications!

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05