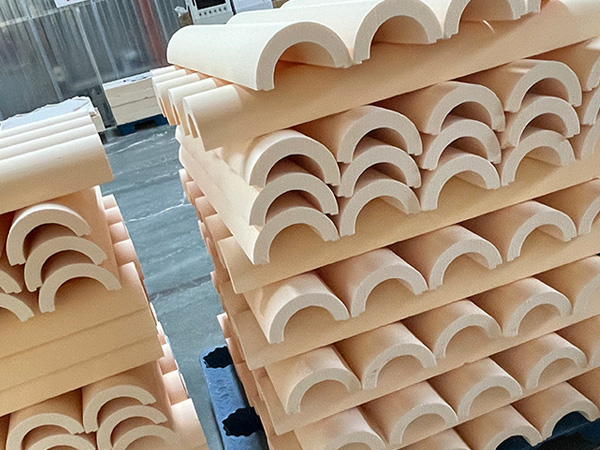

Pipeline Insulation Phenolic Pipe Shell

Our Pipeline Insulation Phenolic Pipe Shell is a high-efficiency thermal solution engineered for demanding industrial and commercial piping applications. Utilizing advanced phenolic foam technology, this precision-engineered insulation system delivers superior thermal performance, exceptional durability, and reliable long-term protection for pipelines in various operating environments.

Key Features & Benefits

Superior Insulation Performance

Ultra-low thermal conductivity (0.020-0.025 W/m·K) ensures maximum energy efficiency

Excellent temperature stability for both hot and cold piping systems

Significantly reduces heat loss/gain compared to traditional insulation materials

Optimized System Design

Pre-fabricated shells for precise fit on straight pipes, elbows, valves and flanges

Custom thickness options from 20mm to 100mm

Available in standard diameters from 15mm to 600mm

Enhanced Durability

Closed-cell structure prevents moisture absorption (<1%)

Resistant to compression, vibration and mechanical stress

Maintains performance integrity over extended service periods

Installation Advantages

Lightweight construction simplifies handling

Split-shell design enables quick installation

Compatible with most mechanical fastening systems

Technical Specifications

Operating temperature range: -40°C to +120°C

Density: 45-55 kg/m³

Compressive strength: ≥150 kPa

Fire performance: Class A rating (self-extinguishing)

Typical Applications

Industrial process piping

HVAC heating/cooling systems

Power generation plants

Oil & gas facilities

Chemical processing plants

District heating networks

Why Choose Our Solution?

Energy Efficient - Reduces thermal losses by up to 30% compared to conventional materials

Cost Effective - Lower lifetime costs through reduced maintenance and replacement needs

Reliable Performance - Consistent insulation properties throughout service life

Simplified Maintenance - Easy access for inspection and repairs

Installation Guidelines

For optimal performance:

Ensure pipe surfaces are clean and dry

Select appropriate adhesive or mechanical fasteners

Properly seal all joints and seams

Protect exterior surfaces if exposed to weather

Conclusion

Our Pipeline Insulation Phenolic Pipe Shell represents the optimal balance of thermal performance, durability and installation efficiency. Engineered to meet the rigorous demands of industrial applications, it provides reliable, long-term insulation protection while reducing energy costs and maintenance requirements.

For project-specific requirements or technical consultation, please contact our engineering team. Custom solutions are available for specialized applications and non-standard pipe configurations.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05