Comparing Thermal Insulation Cotton Density and Performance Levels

2026-01-28 20:20:49

Thermal insulation cotton plays a critical role in modern construction, HVAC systems, and industrial equipment by controlling heat flow and improving energy efficiency. As global energy standards continue to rise, engineers and builders pay closer attention to insulation structure, especially density, because it directly impacts performance, durability, and installation efficiency.

From Manufacturer-managed Production to Factory-level bulk supply, thermal insulation cotton is engineered with precise fiber distribution and compression control. This article explains how density influences performance levels and why choosing the right thermal insulation cotton matters for long-term system reliability.

Introduction to Thermal Insulation Cotton

Insulation materials reduce unwanted heat transfer between different temperature zones. In buildings and mechanical systems, poor insulation leads to energy waste, condensation, and unstable indoor comfort. Thermal insulation cotton offers a flexible, lightweight solution that traps air within its fiber network, slowing conduction and convection.

In professional Manufacturer environments, Production focuses on optimizing fiber orientation and bonding strength. Factory output ensures thermal insulation cotton meets consistent density and thickness requirements for large-scale applications.

What Is Thermal Insulation Cotton?

Thermal insulation cotton is a fibrous material processed into rolls, boards, or panels to resist heat flow. It is typically produced from mineral, glass, or synthetic fibers bonded together to form a porous structure that captures air.

Key properties include:

·Low thermal conductivity

·Good sound absorption

·Lightweight and flexible form

·Fire and moisture resistance (by formulation)

·Easy shaping and cutting

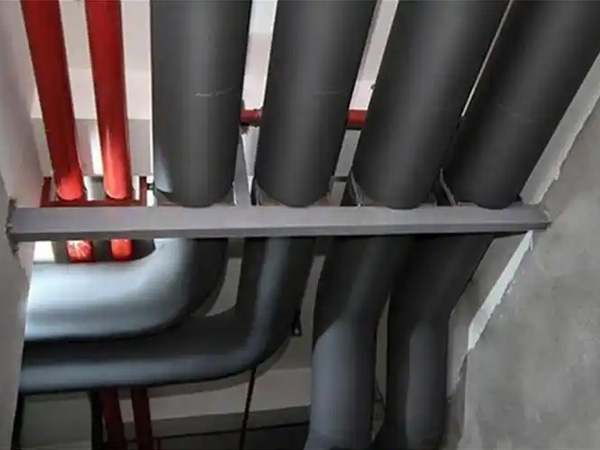

Because of these advantages, thermal insulation cotton is widely used in walls, ceilings, HVAC ducts, industrial pipelines, and equipment enclosures. Manufacturer Production ensures uniform fiber dispersion so Factory bulk supply maintains stable quality from batch to batch.

The Role of Density in Insulation Materials

Density refers to the mass per unit volume of insulation cotton. It defines how tightly fibers are packed and how much air space remains inside the structure.

Density affects:

·Heat transfer behavior

·Mechanical strength

·Compression resistance

·Acoustic absorption

·Long-term shape retention

If thermal insulation cotton is too light, air movement inside can increase heat loss. If it is too dense, solid fiber conduction can raise thermal transfer. Manufacturer Production balances fiber packing during Factory processing to achieve optimal performance.

Common Density Categories Explained

Thermal insulation cotton generally comes in several density ranges:

·Low density: Very lightweight and flexible, suitable for easy handling and light thermal duty.

·Medium density: Balanced structure offering good thermal and acoustic performance.

·High density: More rigid with strong mechanical stability for industrial and vertical installations.

During Factory Production, compression ratios and bonding agents control fiber spacing. This ensures thermal insulation cotton maintains consistent thickness and performance under service loads.

Thermal Efficiency vs. Density

Thermal efficiency depends on how well insulation traps air while minimizing solid heat paths. Density plays a direct role in this balance.

Performance behavior includes:

·Low density materials reduce weight but may allow internal convection.

·Medium density thermal insulation cotton offers the best compromise between trapped air and fiber conduction.

·High density improves structural stability but can slightly increase heat transfer through solids.

Through calibrated Manufacturer Production, Factory output keeps density within controlled ranges so thermal insulation cotton delivers predictable thermal resistance across projects.

Acoustic Performance and Comfort Control

Beyond temperature regulation, thermal insulation cotton also improves indoor acoustic comfort. Density influences how sound waves are absorbed and dissipated.

·Lower density absorbs higher-frequency noise efficiently.

·Medium density provides balanced broadband sound control.

·Higher density enhances low-frequency damping in mechanical rooms and industrial spaces.

With Factory bulk supply, Manufacturer Production supports applications where both thermal and acoustic performance are required, such as HVAC equipment rooms and commercial buildings.

Moisture Behavior and Dimensional Stability

In humid or variable environments, insulation must resist moisture penetration and deformation. Density impacts how water vapor travels through fiber networks.

Well-engineered thermal insulation cotton offers:

·Reduced moisture absorption

·Stable shape under temperature swings

·Lower risk of sagging or settlement

·Longer service life

Factory-controlled Production ensures consistent bonding strength so thermal insulation cotton maintains dimensional stability throughout its operational cycle.

Installation and Handling Advantages

Project efficiency depends heavily on how easily materials can be transported and installed. Density affects cutting, fastening, and overhead application.

Advantages include:

·Low density: Easy to move and fast to cut.

·Medium density: Balanced stiffness for wall and duct insulation.

·High density: Strong support for vertical or exposed systems.

Manufacturer Production designs thermal insulation cotton formats that integrate smoothly with Factory packaging and bulk logistics, helping reduce labor and installation time.

Manufacturer Production and Factory Bulk Supply

Behind reliable thermal insulation cotton is a controlled manufacturing process. Professional Manufacturer systems manage:

·Fiber blending and forming

·Density calibration

·Thickness control

·Mechanical and thermal testing

·Surface treatment and packaging

Factory bulk supply ensures:

·Uniform density across shipments

·Consistent product dimensions

·Reliable logistics handling

·Scalable Production capacity

This integrated approach allows thermal insulation cotton to support both small-scale installations and large industrial or commercial projects worldwide.

How to Select the Right Density Level

Choosing the right thermal insulation cotton density depends on:

·Operating temperature range

·Mechanical load conditions

·Acoustic requirements

·Installation orientation

·Environmental exposure

Working closely with Manufacturer Production planning helps ensure Factory-supplied thermal insulation cotton matches the performance demands of your system.

Conclusion: Density Defines Thermal Insulation Cotton Performance

Thermal insulation cotton achieves its full potential only when density is properly engineered. From lightweight flexibility to high-density mechanical stability, performance levels are directly linked to how fibers are structured and compressed.

Backed by Manufacturer-controlled Production and Factory-level bulk supply, thermal insulation cotton delivers consistent thermal efficiency, acoustic comfort, and durability from fabrication through installation. Selecting the right density is not just a material choice—it is a strategic step toward long-term energy savings and system reliability using professional thermal insulation cotton solutions.

References

GB/T 7714:Papadopoulos A M. State of the art in thermal insulation materials and aims for future developments[J]. Energy and buildings, 2005, 37(1): 77-86.

MLA:Papadopoulos, Agis M. "State of the art in thermal insulation materials and aims for future developments." Energy and buildings 37.1 (2005): 77-86.

APA:Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and buildings, 37(1), 77-86.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...