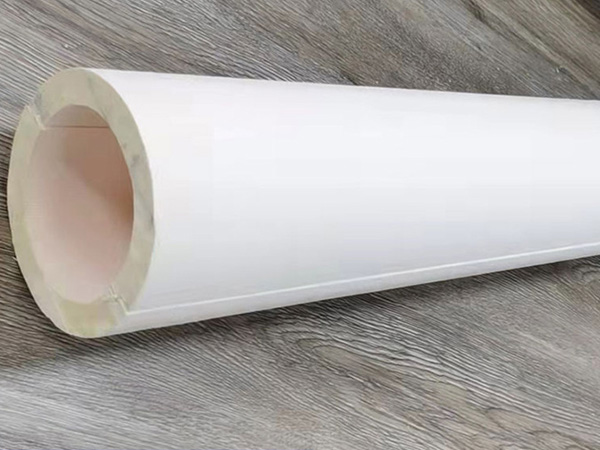

Phenolic Pipe Insulation Section for Cryogenic Systems

2025-09-23 19:47:16

The Role of Insulation in Extreme Cold

Cryogenic environments demand materials that can withstand ultra-low temperatures while maintaining system efficiency and safety. From LNG storage tanks to pharmaceutical cold chains, the insulation used around pipelines is a critical design element. Among the available options, the Phenolic Pipe Insulation Section has earned recognition for its reliability.

Many contractors today turn directly to a China supplier or China factory for sourcing, ensuring bulk supply, cost-effective pricing, and adherence to international standards. Unlike some competitors, phenolic foam combines strong insulation properties with safety and durability, making it a standout choice in global markets.

What Is a Phenolic Pipe Insulation Section?

Made from phenolic foam, this insulation is typically provided in pre-formed pipe sections to simplify installation. The foam is rigid, closed-cell, and specifically engineered for cryogenic performance.

Notable features include:

·Extremely low thermal conductivity, keeping energy loss at a minimum.

·Robust compressive strength, preventing deformation under mechanical load.

·Inherent fire resistance, reducing hazards in industrial facilities.

·Closed-cell moisture barrier, limiting frost and ice buildup.

·Ease of use, as pre-formed sections fit directly over piping.

Why It Excels in Cryogenic Applications

Pipelines and equipment operating at temperatures as low as -180 °C require insulation that can remain stable without cracking or absorbing moisture. Phenolic Pipe Insulation Section fulfills these requirements with a balance of performance and durability.

Key advantages include:

1.Thermal Reliability – Keeps cryogenic systems efficient even at extreme sub-zero levels.

2.Moisture Control – Closed-cell structure resists water ingress and ice formation.

3.Fire Protection – Meets ASTM, ISO, and EN standards for flame retardancy.

4.Long-Term Stability – Retains shape and performance across decades of use.

5.Operational Savings – Reduces cooling losses and energy consumption.

Compared with materials like polyurethane or polystyrene, phenolic foam offers superior fire safety while maintaining equivalent or better insulation.

Where It’s Used in Cryogenic Systems

Phenolic Pipe Insulation Sections are deployed wherever consistent cold performance is mission-critical:

·LNG terminals and pipelines – Minimizes energy loss during transport and storage.

·Refrigerated warehouses – Maintains stable conditions for food and beverages.

·Biopharma facilities – Preserves sensitive vaccines and biologics.

·Petrochemical plants – Protects pipelines running at cryogenic temperatures.

·Marine shipping vessels – Provides insulation for liquefied gas transport.

This wide range of uses highlights its versatility in modern industrial projects.

Additional Benefits Beyond Cold Protection

While temperature control is the main advantage, Phenolic Pipe Insulation Section also provides:

·Light weight, reducing installation effort.

·Dimensional integrity, avoiding warping or shrinking.

·Eco-conscious options, with low-VOC manufacturing practices.

·Budget efficiency, particularly when sourced from a China factory or supplier with bulk supply capacity, making it practical for large-scale installations.

Why Many Choose China-Based Suppliers

Global demand has positioned China as a leading source for phenolic insulation products. Working directly with a China supplier offers multiple benefits:

·Assured bulk availability for mega projects.

·Price competitiveness, lowering overall construction budgets.

·Certified quality, with compliance to ASTM/ISO standards.

·Customization, including pipe sizes and insulation thickness.

·Reliable logistics, eliminating unnecessary intermediaries.

These advantages explain why international buyers continue to prefer China-made phenolic insulation over many competitors.

Conclusion: A Dependable Choice for Cryogenic Engineering

When it comes to protecting cryogenic pipelines and systems, Phenolic Pipe Insulation Section provides unmatched thermal performance, moisture resistance, and fire safety. Its proven durability and compliance with international standards make it a trusted material across industries.

By sourcing from a China supplier or factory with bulk supply capabilities, contractors gain a reliable, cost-effective, and high-quality solution. In comparison to alternatives, Phenolic Pipe Insulation Section remains the benchmark for safe and efficient cryogenic insulation.

References

GB/T 7714:Mougel C, Garnier T, Cassagnau P, et al. Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution[J]. Polymer, 2019, 164: 86-117.

MLA:Mougel, C., et al. "Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution." Polymer 164 (2019): 86-117.

APA:Mougel, C., Garnier, T., Cassagnau, P., & Sintes-Zydowicz, N. (2019). Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution. Polymer, 164, 86-117.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...