Phenolic Pipe Insulation Section: Maintenance Guide

2025-09-29 11:44:58

Extending the Life of Insulation

In industries where pipelines carry cryogenic fluids, chemicals, or HVAC systems, insulation plays a central role in protecting energy efficiency and safety. The Phenolic Pipe Insulation Section stands out for its flame resistance, low thermal conductivity, and structural integrity.

But like all engineered products, its durability depends on how it is maintained after installation. By adopting the right maintenance strategies—and sourcing materials directly from a China supplier or China factory with bulk supply capability—contractors can secure consistent performance while minimizing long-term costs.

What Makes Phenolic Pipe Insulation Section Unique

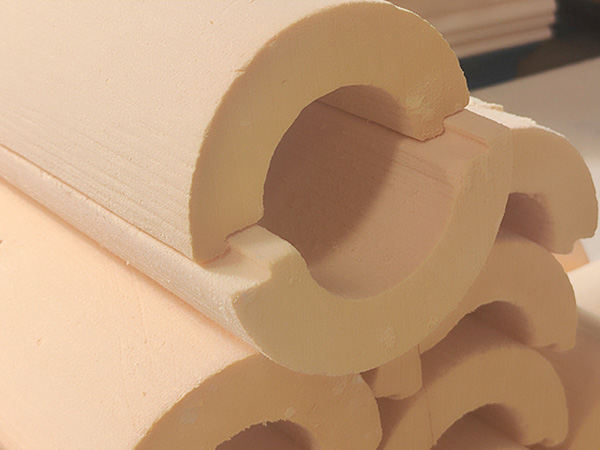

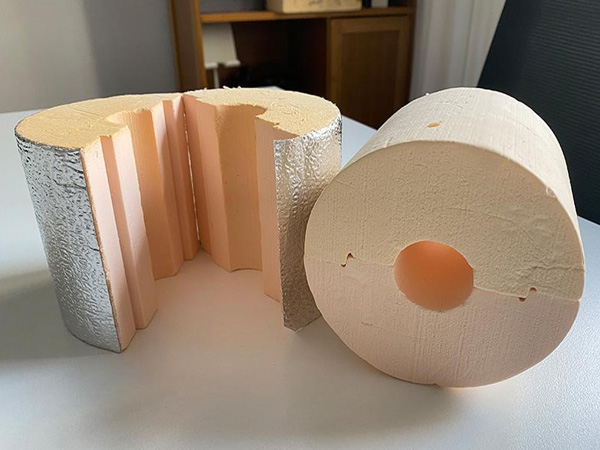

Phenolic insulation is manufactured from rigid phenolic foam, designed in pre-formed sections that fit snugly over piping. Its advantages over many competitor materials include:

·Superior thermal resistance, reducing cold or heat transfer.

·Closed-cell composition, which helps block water vapor and prevents condensation.

·Fire retardancy, with compliance to ASTM and ISO standards.

·Mechanical durability, holding its shape under stress.

·Ease of installation, thanks to factory-made section shapes.

These features make it particularly suited for pipelines in cryogenic plants, cold storage warehouses, and energy-intensive facilities.

Routine Maintenance Practices

To ensure insulation continues performing as intended, inspections and upkeep should be part of a standard maintenance plan.

1.Surface Evaluation

Look for visible cracks, abrasions, or gaps at pipe joints.

2.Moisture Monitoring

Even with its closed-cell design, poor sealing can allow condensation.

3.Thermal Performance Testing

Use temperature sensors or infrared scans to spot cold leaks or energy loss.

4.Support Check

Ensure pipe clamps and fasteners are not compressing or damaging the insulation.

Carrying out these checks every 6–12 months helps detect problems before they escalate.

Environmental Factors and Cleaning

The service environment greatly affects longevity:

·Dust & Debris: Keep insulation surfaces clean with low-pressure air or a dry cloth.

·Humidity Levels: Store and operate below 70% relative humidity when possible.

·Corrosion Risks: Maintain vapor barriers and coatings to stop rust from damaging insulation layers.

A clean and dry environment reduces both material degradation and maintenance frequency.

Repair and Replacement Strategies

While phenolic foam is durable, no insulation is indestructible. Knowing when to repair or replace is essential.

·Minor Cracks → Apply compatible sealants or adhesives.

·Waterlogged Sections → Replace immediately to restore full thermal efficiency.

·Fire or Chemical Exposure → Always replace, since hidden damage can impair performance.

Securing replacement stock directly from a China factory offering bulk supply ensures continuity in large-scale maintenance projects and avoids mismatches with competitor products.

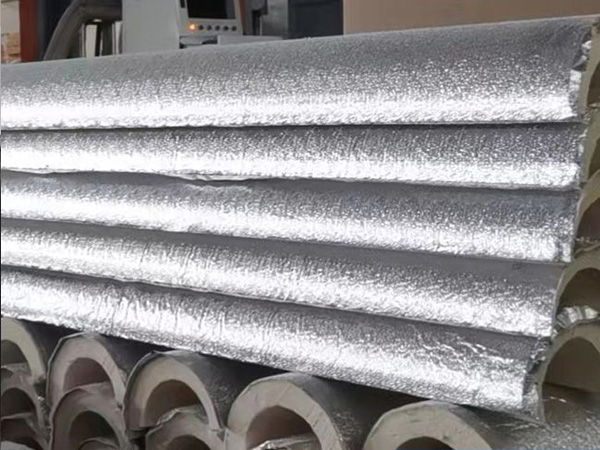

Storage and Handling Best Practices

Proper handling before installation can add years of service life:

·Store indoors, away from direct sunlight and rain.

·Keep packages on pallets, not directly on the ground.

·Wrap or cover during extended storage to block dust and moisture.

·Transport carefully—avoid bending or dropping sections.

These preventive steps keep insulation ready for use without losing quality.

The Advantage of China-Based Suppliers

Many international contractors prefer China suppliers for phenolic insulation because of:

·Bulk supply options, ensuring steady availability.

·Competitive pricing, which lowers overall project budgets.

·Quality certification, aligning with ASTM, EN, and ISO requirements.

·Flexible production, with custom pipe diameters and thicknesses available.

·Global logistics networks, reducing lead times.

For contractors managing multi-site projects, this sourcing model ensures both reliability and cost-effectiveness.

Conclusion: Protecting Performance for the Long Run

The Phenolic Pipe Insulation Section is engineered for strength, efficiency, and safety in environments where failure is not an option. Still, its ability to deliver long-term performance depends on proper inspection routines, environmental management, careful handling, and timely replacements.

By sourcing directly from a China factory or supplier with bulk supply capacity, project managers gain peace of mind—knowing they have dependable, high-quality insulation available whenever it is needed.

Compared to competitor materials, phenolic continues to be the trusted solution for long-term insulation in cryogenic and industrial applications.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...