Phenolic Pipe Insulation Section for District Heating Networks

2025-11-12 12:31:31

In modern district heating networks, energy efficiency and durability are fundamental. Every degree of heat loss can translate into significant operational cost over time. That’s why engineers and contractors increasingly turn to the Phenolic Pipe Insulation Section — an advanced insulation solution designed to deliver superior performance, long service life, and compliance with energy-saving requirements.

As a dedicated phenolic insulation manufacturer with advanced production capabilities, we understand how insulation materials directly impact network efficiency. This article introduces what makes phenolic pipe insulation sections exceptional, how they benefit district heating applications, and why sourcing from an experienced producer ensures consistent quality and performance.

Understanding Phenolic Pipe Insulation Sections

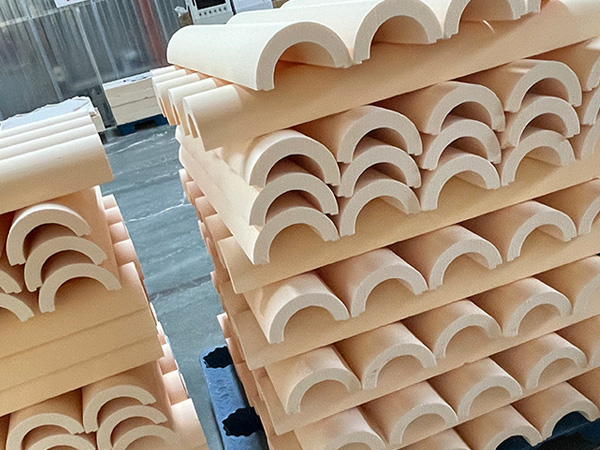

A phenolic pipe insulation section is a rigid, prefabricated form of insulation created from phenolic resin foam. Each section is molded or cut to fit snugly around pipes, often in half-shell designs that simplify installation.

The material’s unique microcellular structure provides extremely low thermal conductivity, making it ideal for retaining heat in high-temperature water or steam systems. Unlike many other foams, phenolic insulation maintains strength and stability even under elevated temperatures, while offering excellent resistance to moisture absorption and fire.

Key characteristics include:

·Thermal conductivity values typically around 0.020–0.025 W/m·K.

·High compressive strength and low density.

·Closed-cell structure for moisture control.

·Compatibility with protective jackets and vapor barriers.

These features combine to make phenolic sections a practical choice where insulation performance and compactness are both required.

Why Phenolic Insulation Excels in District Heating

District heating networks rely on insulated pipelines to transport hot water or steam from central plants to multiple end users. Any heat loss reduces system efficiency. Phenolic insulation provides several distinct benefits for this application:

1.Superior Energy Efficiency

Thanks to its low thermal conductivity, phenolic insulation minimizes heat loss even in thinner layers. This allows engineers to design more compact pipe runs without sacrificing energy performance.

2.Moisture and Corrosion Protection

The closed-cell structure prevents water ingress, protecting both the insulation and the steel pipe from corrosion — particularly important in underground or outdoor systems exposed to humidity.

3.Lightweight and Easy to Install

Prefabricated phenolic sections are light yet strong, enabling quick installation with minimal labor. They can be easily cut, adjusted, and sealed on-site, saving time and cost.

4.Fire Safety

Phenolic foams can be formulated to achieve low smoke and flame spread ratings, contributing to safer network operation and compliance with fire codes.

5.Long-Term Stability

Phenolic materials maintain their structural integrity and insulation properties for decades, ensuring consistent performance and reduced maintenance requirements.

Applications Across District Heating Systems

Phenolic pipe insulation sections are widely used in:

·Buried district heating pipelines to minimize thermal losses over long distances.

·Building connections where compact insulation allows easier routing in confined spaces.

·Plantroom and riser applications requiring thermal continuity and space efficiency.

·Prefabricated module systems, where factory-installed insulation ensures quality consistency.

From residential complexes to industrial-scale heat networks, phenolic insulation ensures maximum efficiency and minimal energy waste.

Installation Tips and Best Practices

Proper installation is crucial to achieving the full benefits of phenolic insulation. Follow these recommendations:

·Surface Preparation: Clean and dry pipe surfaces before applying insulation to ensure full contact.

·Accurate Fitting: Choose correctly sized sections for each pipe diameter to prevent thermal gaps.

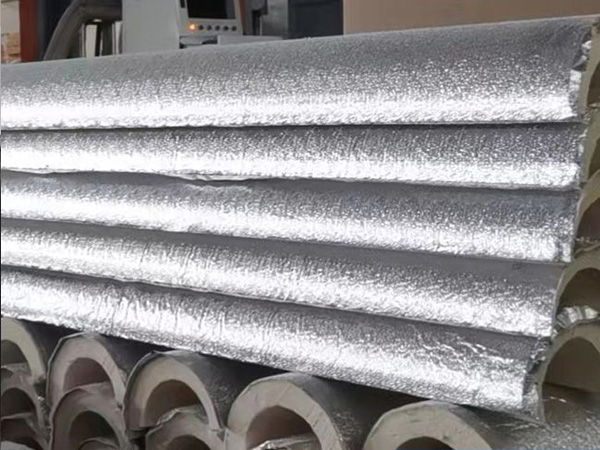

·Joint Sealing: Use vapor barriers or aluminum foil tapes to seal all joints and prevent heat bridging.

·Protection and Cladding: Apply outer jacketing — such as aluminum, PVC, or steel — for mechanical and weather protection.

·Expansion Allowance: In hot water systems, allow for pipe expansion to avoid stress on insulation joints.

Following these guidelines preserves thermal performance and ensures long-term reliability of the insulation system.

Maintenance and Durability

One of the reasons phenolic insulation is favored for district heating is its low maintenance requirement. Periodic inspections are typically limited to checking for mechanical damage, moisture ingress, or deterioration in outer jacketing.

When installed correctly, phenolic insulation retains its properties for decades, maintaining stable heat retention and structural integrity throughout the system’s operational life.

Choosing the Right Manufacturer

Selecting a trustworthy phenolic pipe insulation section manufacturer is essential for project success. A professional manufacturer provides:

·Reliable production capacity with consistent product quality.

·Batch testing data for thermal conductivity and fire resistance.

·Custom sizing and prefabrication options for faster installation.

·Bulk supply solutions for large-scale or ongoing projects.

·Technical documentation and engineering support during system design.

Working directly with an experienced manufacturer guarantees uniform performance, lower project costs, and shorter lead times — vital for contractors managing multiple installation sites.

Conclusion

The Phenolic Pipe Insulation Section represents a cutting-edge solution for modern district heating networks. With outstanding thermal efficiency, moisture resistance, and fire performance, phenolic insulation reduces energy losses and operational costs while extending system life.

Backed by a dedicated manufacturer with strong production capability and bulk supply options, this insulation technology continues to set the benchmark for sustainable heating infrastructure.

For developers, contractors, and utility operators seeking reliable, high-performance insulation, phenolic pipe insulation sections deliver proven value and long-term energy savings — the smart choice for next-generation district heating systems.

References

GB/T 7714:Li F, Jie P, Fang Z, et al. Determining the optimum economic insulation thickness of double pipes buried in the soil for district heating systems[J]. Frontiers in Energy, 2021, 15(1): 170-185.

MLA:Li, Fating, et al. "Determining the optimum economic insulation thickness of double pipes buried in the soil for district heating systems." Frontiers in Energy 15.1 (2021): 170-185.

APA:Li, F., Jie, P., Fang, Z., & Wen, Z. (2021). Determining the optimum economic insulation thickness of double pipes buried in the soil for district heating systems. Frontiers in Energy, 15(1), 170-185.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...