Quality Control Standards for Phenolic Pipe Insulation Section Manufacturing

2025-11-04 12:44:43

In industrial pipelines, HVAC networks, and energy systems, insulation materials play a critical role in maintaining performance efficiency and safety. Among the available materials, the Phenolic Pipe Insulation Section is highly regarded for its excellent thermal resistance, flame retardancy, and moisture protection.

However, these advantages only hold true when manufacturing adheres to strict quality control standards. From resin formulation to dimensional inspection, every stage affects the final insulation performance. Working directly with a phenolic insulation manufacturer in China ensures access to consistent factory-tested bulk supply, backed by professional production control and international compliance.

Overview: What Are Phenolic Pipe Insulation Sections?

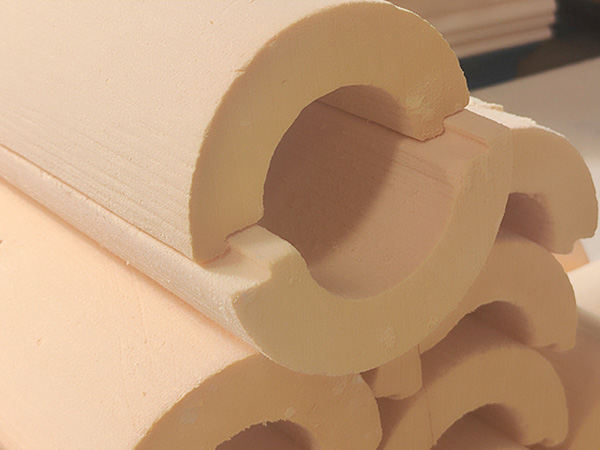

A Phenolic Pipe Insulation Section is a rigid, closed-cell foam product derived from phenol-formaldehyde resin. It’s engineered to provide exceptional insulation efficiency while maintaining mechanical strength and low smoke emission.

Because of its fine, uniform cell structure, it prevents heat transfer and moisture penetration better than many other insulation types. These properties make it ideal for applications such as:

·Industrial pipelines for oil, gas, and chemical plants

·HVAC systems in commercial buildings

·Cold and hot water pipelines

·Refrigeration and cryogenic installations

In essence, phenolic insulation combines lightweight structure with heavy-duty performance, suitable for both high-temperature and sub-zero operations.

Why Quality Control Defines Product Reliability

Manufacturing consistency is what separates premium insulation from substandard materials. Even minor inconsistencies in foam density or curing can cause cracks, air pockets, or poor bonding, reducing overall insulation efficiency.

Therefore, systematic quality control (QC) is implemented across all stages — from raw material verification to final inspection.

Strict QC ensures that every Phenolic Pipe Insulation Section delivered to clients performs reliably in terms of:

·Thermal conductivity

·Fire behavior

·Moisture absorption

·Dimensional stability

·Surface finishing and coating adhesion

Major Standards and Testing Procedures

1. Raw Material Control

The process begins with the inspection of phenolic resin, blowing agents, and curing additives. The resin’s viscosity, pH value, and polymerization stability are measured to ensure predictable foaming and curing. Any deviation can lead to inconsistent density or mechanical weakness.

2. Density and Cell Structure Evaluation

Each foam block undergoes density testing (typically 35–80 kg/m³) and microscopic cell analysis. Uniform density across the section ensures steady thermal resistance and structural strength, essential for maintaining tight pipe fits under temperature fluctuation.

3. Thermal Conductivity Measurement

Phenolic foam is known for its low λ-value, generally below 0.025 W/m·K at 25°C.

Laboratories test samples according to ASTM C518 or ISO 8301, confirming their ability to minimize heat transfer over time.

4. Fire and Smoke Performance

One of phenolic insulation’s greatest strengths is its non-flammable, low-smoke performance. Testing per ASTM E84, BS 476 Part 7, or EN 13501-1 determines the fire classification.

Premium products consistently achieve Class 0 or Class 1 ratings, meaning they resist ignition and emit minimal smoke even under high heat.

5. Dimensional Precision and Cutting Accuracy

CNC-controlled equipment ensures that each insulation section meets pipe dimension specifications with ±1 mm tolerance. Visual inspection verifies edge smoothness, uniform thickness, and consistent coating coverage.

6. Moisture and Aging Resistance

Accelerated aging tests simulate prolonged exposure to heat and humidity.

A quality phenolic section retains over 90% of its thermal and mechanical properties after extended environmental stress, ensuring long service life in the field.

The Advantage of Choosing a Chinese Manufacturer

Collaborating with a phenolic pipe insulation section manufacturer in China provides global buyers with significant benefits. China’s advanced manufacturing base, combined with automated equipment and skilled labor, ensures superior quality at competitive prices.

Here’s why Chinese suppliers stand out:

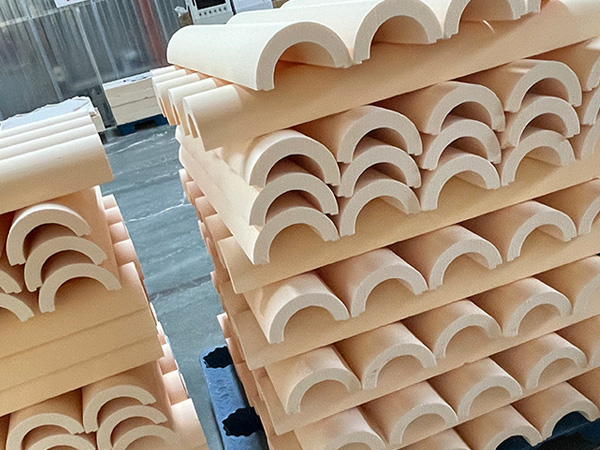

1.Factory-Level Bulk Supply – Large-scale automated foaming and cutting lines enable consistent high-volume production.

2.Rigorous Testing Protocols – In-house laboratories monitor every production stage to maintain repeatable quality.

3.Customization Options – OEM and tailored dimensions available for various industrial and HVAC applications.

4.Global Export Experience – Compliance with ASTM, BS, and EN standards for cross-border projects.

By partnering directly with a China insulation supplier, customers secure factory-verified quality, cost-effective bulk orders, and efficient international logistics — all backed by certified performance documentation.

Conclusion

Strict quality control standards are the backbone of reliable Phenolic Pipe Insulation Section production.

From precise resin formulation to thermal, fire, and dimensional testing, every process step determines the material’s final safety and efficiency.

Choosing a trusted phenolic insulation manufacturer in China guarantees factory-tested, bulk-supplied insulation materials that meet or exceed global performance expectations.

In a world increasingly focused on energy efficiency and safety, phenolic insulation manufactured under consistent quality control not only protects pipelines but also supports long-term sustainability and operational excellence.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...