Reducing Heat Loss in Industrial Pipelines with Phenolic Pipe Insulation

2026-01-31 20:51:35

Phenolic Pipe Insulation Section solutions are widely applied in industrial pipeline systems to minimize thermal loss, improve energy efficiency, and protect process stability. In industries where fluids and gases travel long distances under controlled temperatures, even small heat losses can result in higher operating costs, condensation problems, and reduced system efficiency.

With Manufacturer-controlled Production and Factory-scale bulk supply, phenolic insulation sections are engineered to provide consistent thermal performance, fire safety, and long-term durability. This article explains how phenolic pipe insulation helps reduce heat loss and why it is an effective solution for industrial pipeline projects.

Introduction to Pipeline Heat Loss Challenges

Industrial pipelines carry steam, hot water, chilled fluids, and process chemicals across large facilities. Without proper insulation, these pipelines exchange heat with the surrounding environment, leading to energy waste and unstable process temperatures.

Common problems caused by heat loss include:

·Increased fuel or electricity consumption

·Temperature drops along the pipeline

·Condensation and corrosion

·Safety risks for personnel

·Reduced system lifespan

Phenolic Pipe Insulation Section products provide a high-performance thermal barrier that limits heat transfer while maintaining mechanical integrity. Manufacturer Production focuses on precision forming so Factory output meets the demanding conditions of industrial environments.

What Is Phenolic Pipe Insulation Section?

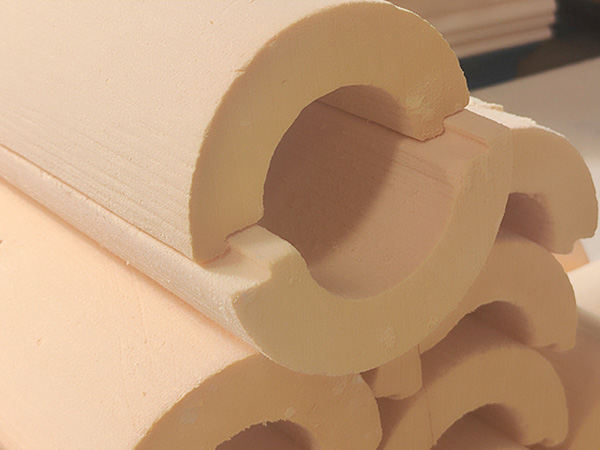

A Phenolic Pipe Insulation Section is a rigid, closed-cell foam insulation formed into pipe-shaped segments. It is produced from phenolic resin expanded into a lightweight cellular structure that traps air and resists heat flow.

Key features include:

·Low thermal conductivity

·Closed-cell moisture resistance

·High compressive strength

·Dimensional stability

·Fire and smoke performance

During Production, Manufacturer processes control cell size and density. Factory bulk supply ensures uniform thickness and precise inner diameters so the insulation fits securely around industrial pipelines.

Why Heat Loss Control Matters in Industry

In industrial operations, temperature consistency directly affects efficiency and product quality. Heat loss in pipelines forces systems to work harder to maintain required temperatures.

Effective insulation:

·Reduces operational energy demand

·Stabilizes process temperatures

·Prevents condensation on cold pipes

·Enhances workplace safety

·Protects pipeline surfaces

By using Phenolic Pipe Insulation Section materials, facilities benefit from predictable thermal resistance supported by Manufacturer Production quality control and Factory-scale manufacturing consistency.

Thermal Performance of Phenolic Insulation

The thermal performance of phenolic insulation is driven by its closed-cell structure. Air trapped within microscopic cells reduces conductive and convective heat transfer.

Advantages include:

·Low thermal conductivity values

·Stable performance over time

·Reduced heat gain or loss

·Efficient temperature retention

Through calibrated Production, Manufacturer systems maintain density balance so Factory-supplied phenolic pipe insulation sections deliver consistent heat-loss reduction across entire pipeline networks.

Fire Safety and Operational Reliability

Fire behavior is critical in industrial facilities where pipelines often carry flammable or high-temperature media. Phenolic insulation provides strong fire safety characteristics.

Safety benefits:

·Low flame spread

·Low heat release

·Reduced smoke generation

·Improved evacuation conditions

Factory-controlled Production integrates testing and material formulation to ensure Phenolic Pipe Insulation Section products meet safety expectations for industrial pipeline environments.

Moisture Resistance and Corrosion Protection

Moisture intrusion can destroy insulation performance and accelerate corrosion under insulation (CUI). Phenolic insulation’s closed-cell structure helps block water migration.

Key advantages:

·Low water absorption

·Vapor resistance

·Reduced condensation risk

·Protection of pipe surfaces

Manufacturer Production ensures proper cell sealing and surface finishing so Factory bulk supply delivers insulation sections capable of long-term moisture resistance in demanding conditions.

Lightweight Design and Installation Efficiency

Installation efficiency affects both project cost and schedule. Phenolic pipe insulation sections are lightweight yet rigid, making them easy to handle and install.

Installation benefits:

·Faster positioning around pipes

·Reduced labor load

·Easy cutting and fitting

·Secure mechanical fastening

With Manufacturer Production planning and Factory packaging systems, Phenolic Pipe Insulation Section products are delivered in bulk with consistent geometry, simplifying installation across large pipeline systems.

Manufacturer Production and Factory Bulk Supply

High-quality insulation depends on controlled manufacturing. Professional Manufacturer operations manage:

·Resin formulation

·Foam expansion control

·Density calibration

·Section cutting and shaping

·Surface treatment

Factory bulk supply ensures:

·Uniform thickness

·Accurate pipe diameters

·Consistent quality

·Reliable logistics handling

This Production system allows Phenolic Pipe Insulation Section materials to support small projects and large industrial pipeline installations with equal reliability.

Typical Applications in Industrial Pipelines

Phenolic insulation sections are commonly used in:

·Steam pipelines

·Hot water networks

·Chilled water systems

·Chemical process lines

·HVAC industrial piping

Because of stable thermal performance and fire behavior, Manufacturer Production supports Factory bulk supply for energy, petrochemical, pharmaceutical, and building services industries.

How to Select the Right Insulation System

When choosing Phenolic Pipe Insulation Section materials, consider:

·Operating temperature range

·Pipe diameter and layout

·Environmental exposure

·Fire safety requirements

·Installation conditions

Working with Manufacturer Production planning ensures Factory-supplied insulation sections match your system’s thermal and mechanical performance requirements.

Conclusion: Phenolic Pipe Insulation Section for Heat Loss Control

Phenolic Pipe Insulation Section solutions offer an efficient way to reduce heat loss in industrial pipelines while improving safety, durability, and energy efficiency. Their closed-cell structure, low thermal conductivity, and moisture resistance make them ideal for maintaining stable temperatures in demanding industrial environments.

Supported by Manufacturer-controlled Production and Factory-level bulk supply, Phenolic Pipe Insulation Section products deliver consistent performance from fabrication to installation. Choosing phenolic insulation is not only about protecting pipelines—it is about optimizing industrial energy use and ensuring long-term operational reliability with professional Phenolic Pipe Insulation Section systems.

References

GB/T 7714:Papadopoulos A M. State of the art in thermal insulation materials and aims for future developments[J]. Energy and buildings, 2005, 37(1): 77-86.

MLA:Papadopoulos, Agis M. "State of the art in thermal insulation materials and aims for future developments." Energy and buildings 37.1 (2005): 77-86.

APA:Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and buildings, 37(1), 77-86.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...