Common Mistakes to Avoid When Installing Phenolic Pipe Insulation Section

2025-08-29 17:06:57

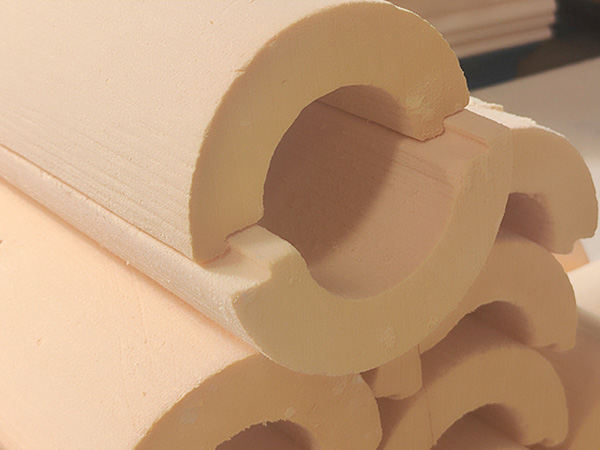

The performance of Phenolic Pipe Insulation Section depends not only on the material’s inherent properties but also on how well it is installed. While this insulation type is valued for its low thermal conductivity, fire safety, and lightweight nature, poor installation practices can undermine its advantages. Many problems—such as heat loss, moisture damage, and mechanical failure—can be traced back to avoidable mistakes during installation.

This article examines the most common errors encountered in the field and provides actionable strategies to ensure a flawless installation process.

1. Failing to Prepare the Pipe Surface

Skipping proper surface preparation is one of the first and most damaging mistakes. Dust, oil, or residual moisture on pipes creates barriers that weaken adhesion and compromise insulation performance.

Prevention Tips:

·Remove rust, dirt, and grease before installation.

·Confirm that the pipe is fully dry.

·Treat or repair any corrosion prior to fitting insulation.

Well-prepared surfaces create a stable foundation, ensuring Phenolic Pipe Insulation Section performs as intended.

2. Using Incorrect Dimensions or Poor Cutting

Ill-fitting insulation—whether too loose or too tight—can result in heat leakage or compression damage. Rough or uneven cuts also create visible gaps that reduce efficiency.

Prevention Tips:

·Take precise pipe measurements before selecting insulation sizes.

·Use proper cutting tools to achieve smooth, even edges.

·Follow product specifications closely to match diameter and thickness.

Precision ensures a snug fit, maximizing thermal control and minimizing waste.

3. Neglecting Joint and Seam Sealing

Joints are weak points in any insulation system. If not properly sealed, they can permit air and moisture to enter, accelerating heat transfer and corrosion.

Prevention Tips:

·Apply adhesives or sealants compatible with Phenolic Pipe Insulation Section.

·Carefully seal both longitudinal seams and circumferential joints.

·Reinforce with vapor barriers if working on chilled or cold-water lines.

Strong seals not only conserve energy but also safeguard the pipe itself.

4. Forgetting to Allow for Thermal Expansion

Temperature variations naturally cause piping to expand and contract. Without accounting for this movement, insulation may crack, shift, or lose contact with the pipe.

Prevention Tips:

·Leave adequate space to accommodate thermal expansion.

·Avoid over-compression or excessive strapping.

·Where necessary, select flexible sealing compounds.

Factoring in expansion keeps insulation intact throughout system cycles.

5. Insufficient Support at Contact Points

Improper support systems can compress insulation, leaving flat spots or gaps that weaken thermal protection. Over time, this can lead to sagging and increased maintenance needs.

Prevention Tips:

·Choose supports designed for insulated piping.

·Use load-distribution shields or saddles at support locations.

·Verify weight is evenly spread to prevent localized damage.

Proper support helps maintain the structural integrity of Phenolic Pipe Insulation Section.

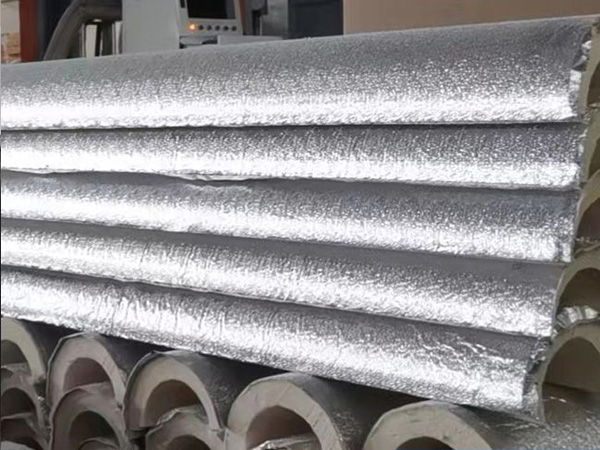

6. Poor Moisture Protection

Moisture is one of the biggest threats to insulation performance. Once water enters, thermal resistance drops, and microbial growth may develop.

Prevention Tips:

·Apply protective jacketing for outdoor systems.

·Add vapor barriers for refrigeration or chilled water applications.

·Conduct routine inspections and replace damaged cladding immediately.

Moisture control preserves both efficiency and hygiene.

7. Skipping Post-Installation Inspections

Even after careful installation, minor defects often remain unnoticed if no final inspection is performed. These small flaws can eventually undermine the entire insulation system.

Prevention Tips:

·Inspect every seam, joint, and protective layer.

·Check for proper alignment and continuous coverage.

·Document issues and correct them promptly.

Final checks guarantee that the installed Phenolic Pipe Insulation Section meets performance expectations.

Conclusion

The benefits of Phenolic Pipe Insulation Section—energy efficiency, fire safety, and long-term cost savings—can only be fully realized with correct installation practices. Mistakes such as inadequate surface preparation, poor cutting, neglecting seals, or ignoring moisture protection can all compromise results.

By paying attention to detail, accommodating pipe movement, and carrying out thorough inspections, you ensure that the insulation system delivers maximum efficiency and durability. In short, success lies not just in the quality of the product but also in the precision of its installation.

Installing Phenolic Pipe Insulation Section the right way transforms it into a reliable, high-performance solution that continues to provide value throughout its service life.

References

GB/T 7714:Schroer D, Hudack M, Soderquist M, et al. Rigid polymeric foam boardstock technical assessment[J]. The Dow Chemical Company, 2011.

MLA:Schroer, Dan, et al. "Rigid polymeric foam boardstock technical assessment." The Dow Chemical Company (2011).

APA:Schroer, D., Hudack, M., Soderquist, M., & Beulich, I. (2011). Rigid polymeric foam boardstock technical assessment. The Dow Chemical Company.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...