Comparing Phenolic Pipe Insulation Section with Rubber Foam Pipe Insulation

2025-09-01 18:57:18

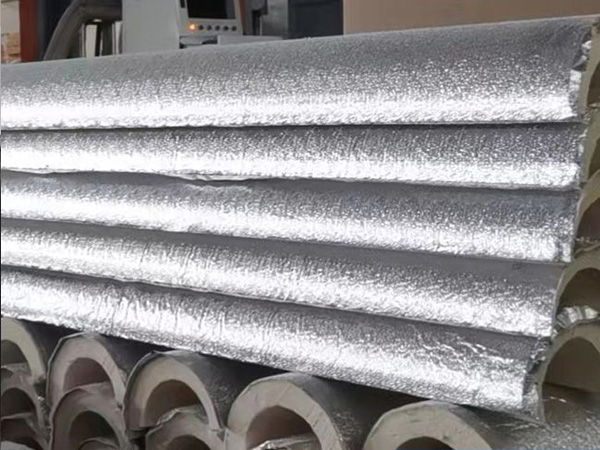

The effectiveness of a piping system does not rely solely on design and flow capacity—it also depends heavily on the insulation material that protects it. Among the commonly discussed options are Phenolic Pipe Insulation Section and rubber foam pipe insulation. Both are intended to conserve energy, minimize heat transfer, and limit condensation, yet they differ in structure, performance, and long-term reliability.

This article explores these differences, with a particular emphasis on the strengths that make Phenolic Pipe Insulation Section stand out in demanding applications.

1. Thermal Efficiency

Insulation is primarily judged by its ability to resist heat flow.

·Phenolic Pipe Insulation Section: Characterized by a very low thermal conductivity, it delivers superior energy conservation. It performs consistently in systems where maintaining steady temperatures is critical, such as chilled-water pipelines.

·Rubber Foam Pipe Insulation: Provides effective thermal resistance, but its conductivity is usually higher than that of phenolic foam, meaning more energy can be lost under equivalent conditions.

Insight: For strict efficiency targets, Phenolic Pipe Insulation Section offers better insulation value.

2. Fire Behavior and Safety

Fire performance often determines material acceptance in high-occupancy facilities.

Phenolic Pipe Insulation Section: Exhibits excellent fire resistance, with low flame spread and reduced smoke release. This minimizes risks in fire emergencies, supporting safer evacuation.

Rubber Foam Pipe Insulation: While offering some resistance, it generally emits thicker smoke and may release toxic gases under combustion.

Insight: From a fire-safety perspective, Phenolic Pipe Insulation Section has a clear edge.

3. Moisture Control

Moisture intrusion can cause thermal bridging and corrosion under insulation.

·Phenolic Pipe Insulation Section: Built with a closed-cell structure, it resists water absorption effectively. When correctly sealed, it keeps pipes dry and protected over time.

·Rubber Foam Pipe Insulation: Also closed-cell and moisture resistant, but can degrade faster in prolonged humid environments.

Insight: Both materials defend against condensation, but phenolic insulation is generally more stable long term.

4. Strength and Service Life

Durability is a key factor for facilities that expect long operational life.

·Phenolic Pipe Insulation Section: Offers superior rigidity and compressive strength. It maintains its shape and properties even under continuous service conditions.

·Rubber Foam Pipe Insulation: More flexible, which aids installation, but may tear or lose form with age.

Insight: For projects emphasizing long service life, Phenolic Pipe Insulation Section delivers greater reliability.

5. Installation Flexibility

Installation demands vary with project scale and pipe complexity.

·Phenolic Pipe Insulation Section: Delivered as precision-cut segments, it requires accurate placement and sealing. Though installation takes more care, the result is uniform and highly efficient.

·Rubber Foam Pipe Insulation: Flexible and easy to trim, making it useful for bends and irregular runs. It allows quicker installations but can compromise uniformity.

Insight: Rubber foam wins in flexibility, but phenolic insulation rewards precision with better long-term results.

6. Cost and Lifecycle Value

While price is a deciding factor, long-term performance should not be overlooked.

·Phenolic Pipe Insulation Section: The upfront investment may be higher, but reduced energy waste, better fire safety, and long service life lower overall costs across its lifespan.

·Rubber Foam Pipe Insulation: Typically less costly initially, yet it may require earlier replacement in tough environments, raising lifecycle expenses.

Insight: Viewed over time, Phenolic Pipe Insulation Section often proves the more economical choice.

Conclusion

Choosing between phenolic and rubber foam insulation depends on priorities—whether quick installation and flexibility, or maximum efficiency and long-term resilience. For facilities where energy conservation, fire safety, and extended durability are essential, Phenolic Pipe Insulation Section consistently outperforms. Rubber foam remains useful for simpler or smaller projects that favor installation speed, but in demanding conditions phenolic insulation stands as the more dependable option.

By recognizing the unique strengths of Phenolic Pipe Insulation Section and applying proper installation practices, engineers and facility managers can ensure reliable thermal performance, enhanced safety, and cost savings throughout the system’s service life.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...