Complete Buyer’s Guide: Phenolic Insulation Board and Phenolic Pipe Insulation Section

2025-09-04 19:24:59

For architects, engineers, and contractors aiming to improve building performance, Phenolic Insulation Board has become a trusted solution. Known for its thermal efficiency, light weight, and excellent fire safety profile, it plays a vital role in modern energy-conscious design. Equally important, Phenolic Pipe Insulation Section offers targeted protection for piping networks, helping to maintain system efficiency while extending service life.

This buyer’s guide provides a clear overview of both products, highlighting their features, advantages, applications, and best practices for installation.

Understanding Phenolic Insulation Board

Phenolic Insulation Board is a rigid foam panel produced from phenolic resins. Unlike many traditional insulation materials, it offers a unique balance of high thermal resistance and low density, making it suitable for walls, roofs, and floors.

Core Features

·Superior Thermal Resistance – Keeps indoor spaces comfortable while reducing energy costs.

·Enhanced Fire Performance – Produces very little smoke and slows flame spread.

·Moisture Control – Closed-cell structure reduces water absorption and mold risk.

·Lightweight Handling – Easy to cut and install with minimal labor effort.

By incorporating Phenolic Insulation Board into the building envelope, project teams gain measurable efficiency and long-term resilience.

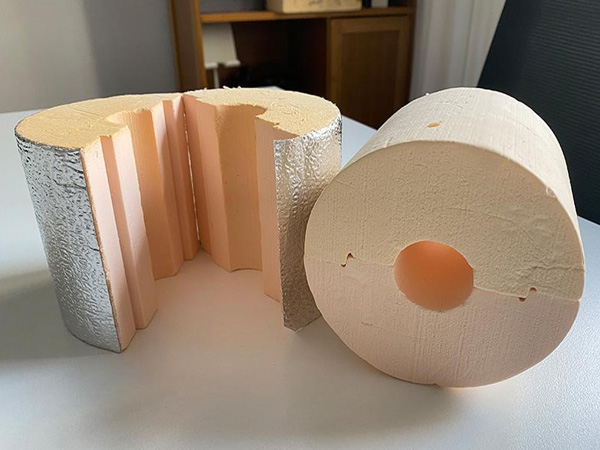

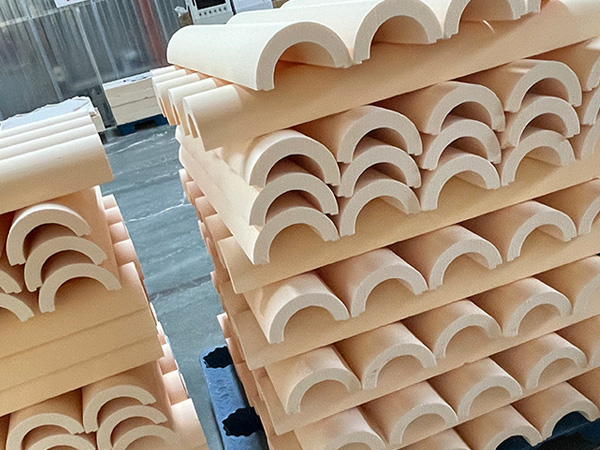

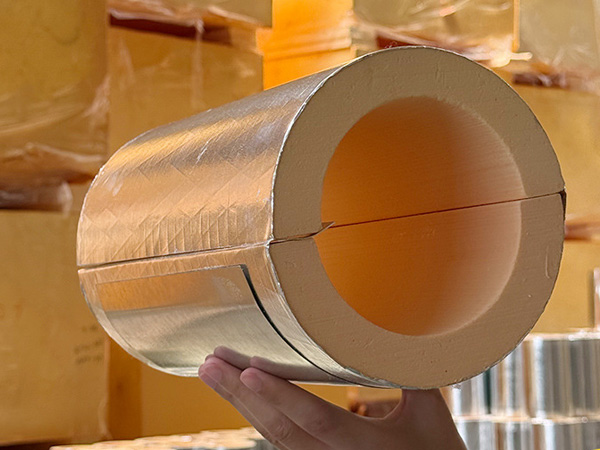

Exploring Phenolic Pipe Insulation Section

Designed specifically for cylindrical systems, Phenolic Pipe Insulation Section is pre-formed to match different pipe diameters. It protects both hot and cold service lines by minimizing thermal losses and preventing surface condensation.

Core Features

·Thermal Stability – Consistent performance across heating and cooling systems.

·Durability – Resistant to deformation, compression, and aging.

·Safety – Offers excellent fire resistance, ideal for mechanical spaces.

·Moisture Protection – Often paired with vapor barriers for chilled or outdoor applications.

In commercial and industrial environments, Phenolic Pipe Insulation Section ensures pipelines remain efficient and secure for decades.

Why These Insulation Types Matter

1. Energy Conservation

Both insulation forms reduce heat transfer, leading to measurable energy savings and reduced operational costs.

2. Fire Safety Compliance

Phenolic materials exceed many building code requirements due to their fire performance and low smoke release.

3. Moisture Resistance

Their closed-cell foam design makes them resistant to water penetration, reducing corrosion risks.

4. Ease of Use

Lightweight properties simplify handling and lower labor intensity on-site.

5. Long-Term Return on Investment

Once installed properly, Phenolic Insulation Board and pipe sections can remain effective for decades, lowering maintenance costs.

Key Applications

Phenolic Insulation Board

·Wall and façade insulation

·Flat and pitched roofing systems

·Floor insulation under screeds

·HVAC ducting

Phenolic Pipe Insulation Section

·Hot water and steam pipelines

·Refrigerated water and cooling systems

·Industrial plant piping

·Energy distribution networks

By addressing both structural and mechanical needs, these solutions deliver system-wide efficiency.

Best Practices for Installation

1.Preparation – Clean and dry surfaces thoroughly before installation.

2.Accurate Sizing – Measure and cut carefully to avoid gaps or compression damage.

3.Seam Sealing – Apply adhesives or tapes designed for phenolic materials to close joints.

4.Moisture Protection – For cold or outdoor lines, always add a vapor barrier or weatherproof cladding.

5.Inspection – After installation, check for alignment, sealing quality, and overall coverage.

These practices ensure that Phenolic Insulation Board and Phenolic Pipe Insulation Section deliver maximum effectiveness throughout their lifecycle.

Long-Term Advantages

The decision to use phenolic insulation goes beyond immediate thermal savings. It provides lasting protection against energy loss, minimizes environmental impact, and enhances fire safety. With global emphasis on sustainability, these products support greener building design without compromising durability.

By selecting Phenolic Insulation Board for structures and Phenolic Pipe Insulation Section for mechanical systems, professionals secure performance, safety, and compliance with modern construction standards.

Conclusion

Insulation is more than a building accessory—it’s a safeguard for efficiency, safety, and comfort. Phenolic Insulation Board and Phenolic Pipe Insulation Section offer a proven combination of energy savings, fire resistance, and moisture protection.

When properly specified and installed, these materials not only reduce operational costs but also extend the service life of buildings and piping systems. In today’s construction environment, they represent one of the smartest long-term investments for both residential and industrial projects.

Ultimately, choosing Phenolic Insulation Board ensures reliable performance for building envelopes, while Phenolic Pipe Insulation Section guarantees consistent protection for pipelines. Together, they form a complete insulation strategy that meets the demands of modern energy-efficient design.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...