Customized Size Aluminum Foil Foam Pipe Shell: Specifications, Applications, and Advantages

2026-02-22 10:42:06

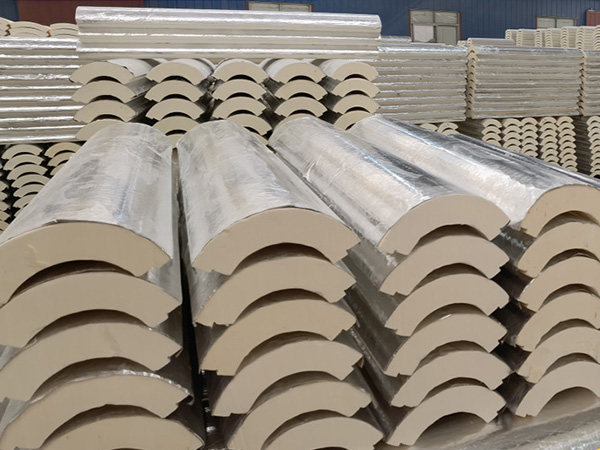

Pipeline insulation systems often require precise matching between insulation materials and pipe dimensions. Standard sizes cannot always meet the needs of complex projects, which is why Customized Size Aluminum Foil Foam Pipe Shellhas become an increasingly important solution. As a professional manufacturer with stable production capability and bulk supply capacity, customized aluminum foil foam pipe shells are designed to deliver reliable insulation performance while adapting to diverse pipeline systems.-

Specifications of Customized Size Aluminum Foil Foam Pipe Shell

Customized size aluminum foil foam pipe shells are manufactured according to specific project requirements. Through controlled **production processes, manufacturers can adjust key parameters to ensure accurate fitting and consistent performance.

Typical specifications include:

Inner diametercustomized to match different pipe sizes

Wall thickness adjusted based on insulation requirements

Length options suitable for easy transportation and installation

Aluminum foil composite surface for enhanced protection and durability

With standardized manufacturing management, customized production ensures dimensional accuracy while maintaining stable insulation properties.

Applications in Pipeline Insulation Systems

Customized Size Aluminum Foil Foam Pipe Shell** is widely used across various pipeline insulation scenarios, including:

HVAC hot and cold water pipelines

Central air conditioning systems

Industrial process piping

Outdoor pipelines requiring surface protection

Commercial and public building insulation systems

Thanks to flexible production arrangements, manufacturers can support **small-batch customization as well as large-volume production**, meeting the demands of both specialized projects and large-scale installations.

Advantages of Customized Size Aluminum Foil Foam Pipe Shell

1. Precise Fit and Reduced Material Waste

Customized sizing ensures a close fit to the pipeline, reducing gaps and minimizing insulation material waste during installation.

2. Improved Thermal Insulation Performance

Accurate thickness and tight installation help maintain consistent thermal insulation efficiency along the entire pipeline.

3. Enhanced Surface Protection

The aluminum foil composite layer provides additional resistance to moisture, mechanical damage, and environmental exposure.

4. Flexible Production and Supply

As a manufacturer, the ability to adjust production parameters allows for both customized orders and bulk supply, supporting various project timelines.

5. Easy Installation and Maintenance

Properly sized pipe shells simplify installation and reduce on-site modification work, improving overall construction efficiency.

Manufacturer and Production Capability

A professional manufacturer focuses on stable raw material sourcing, standardized production lines, and consistent quality control. Through scalable production capacity, customized aluminum foil foam pipe shells can be supplied efficiently for engineering projects, infrastructure development, and long-term insulation solutions.

From specification confirmation to final delivery, production planning ensures reliable lead times and consistent product performance.

Conclusion

Customized Size Aluminum Foil Foam Pipe Shell provides a practical and efficient solution for modern pipeline insulation systems. With flexible specifications, wide application ranges, and clear performance advantages, it meets the diverse needs of HVAC and industrial insulation projects. Supported by professional manufacturing and reliable production capacity, customized pipe shells offer long-term value for pipeline insulation solutions.

References

1. Pipeline Insulation Design and Installation Guidelines

2. Aluminum Foil Composite Insulation Materials in HVAC Systems

3. Thermal Performance Evaluation of Foam Pipe Insulation

4. Industrial Pipeline Insulation Standards and Practices

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...