Quality Control and Testing Methods for Phenolic Foam Board Installation

2025-06-18 11:40:19

Quality Control and Testing Methods for Phenolic Foam Board Installation

1. Key Quality Control Measures

To ensure optimal performance, the following must be strictly monitored during installation:

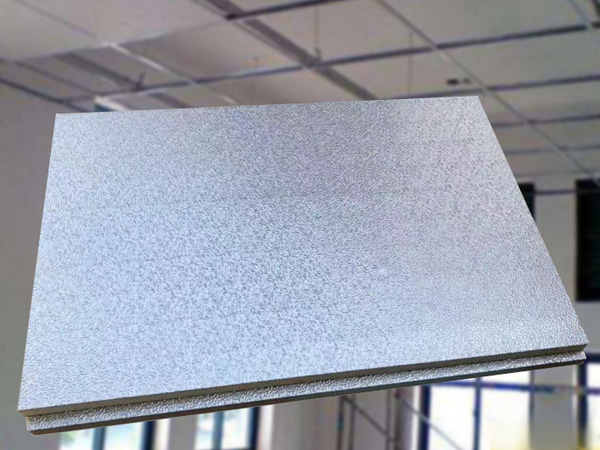

Material Inspection

Verify density (typically 40–60 kg/m³), thermal conductivity (0.018–0.025 W/m·K), and fire rating (Class A/B).

Check for surface cracks, delamination, or moisture absorption before use.

Storage & Handling

Store in a dry, shaded environment to prevent UV degradation.

Avoid mechanical damage during transport (e.g., bending, impact).

Installation Best Practices

Adhesive Application: Use compatible glue (e.g., polyurethane-based) for full-surface bonding to prevent air gaps.

Joint Sealing: Gaps >2 mm must be filled with foam sealant or tape to avoid thermal bridging.

Mechanical Fixing: Use corrosion-resistant fasteners (stainless steel) for outdoor/chemical environments.

2. Critical Testing Methods

In-Situ Thermal Resistance Check

Infrared thermography to detect cold spots or insulation voids.

Water Absorption Test (ASTM C272)

Immerse samples for 24 hours; absorption should be <5% by volume.

Compressive Strength Test (ASTM D1621)

Ensure boards meet ≥100 kPa for wall applications, ≥250 kPa for floors.

Fire Performance Tests

Flame spread index (ASTM E84) and smoke density (UL 723) verification.

3. Common Defects & Solutions

Defect

Cause

Remediation

Panel warping Improper storage Replace, ensure flat stacking

Poor adhesion Incorrect adhesive Reapply with compatible glue

Thermal bridging Unsealed joints Fill gaps with backer rod + sealant

4. Post-Installation Audit

Conduct airtightness testing (e.g., blower door test) for building envelopes.

Monitor long-term moisture content (hygrometer probes in high-humidity zones).

Note: For chemical plants/cryogenic use, additional corrosion/thermal cycling tests (e.g., ASTM C591) may be required.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...