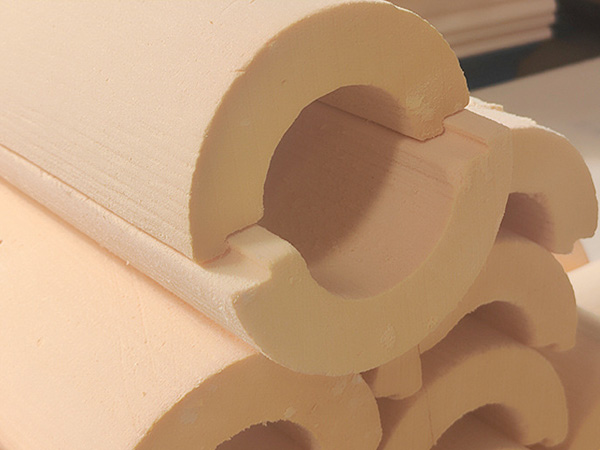

Fire Resistance Characteristics of Phenolic Insulation Pipe Sections

2025-06-18 18:23:15

Phenolic foam pipe insulation offers superior fire performance compared to conventional plastic-based insulation materials. Below is a detailed analysis of its key fire safety properties and applications in high-risk environments.

1. Inherent Fire-Resistant Composition

Thermoset Polymer Structure

Phenolic resin forms a highly crosslinked molecular structure that chars rather than melts when exposed to fire, preventing dripping and flame spread.

Fire Retardant Additives

Contains nitrogen and phosphorus-based compounds that release flame-suppressing gases when heated (endothermic reaction).

2. Critical Fire Performance Metrics

Flame Spread Resistance

Achieves Class B1 (GB 8624) / Euroclass B-s1,d0 (EN 13501-1) with:

Flame spread index ≤25 (ASTM E84)

Smoke density rating ≤50 (NBS smoke chamber test)

High Temperature Stability

Maintains structural integrity up to 150°C continuous service, with short-term resistance to 250°C during fire events.

Limited Toxic Emissions

Halogen-free formulation produces primarily CO₂ and H₂O during decomposition (unlike PVC-based foams).

3. Fire Testing Compliance

Large-Scale Fire Tests

Passes BS 476 Part 6 & 7 for flame propagation and surface spread.

Industrial Standards

Certified for NFPA 274 (pipe insulation flammability) and IMO FTP Code for marine applications.

4. Failure Prevention Mechanisms

Char Formation

Develops a protective carbonized layer at 300-400°C, slowing heat transfer to underlying pipes.

Self-Extinguishing

Ceases burning within <3 seconds after flame removal (UL 94 V-0 equivalent).

5. High-Risk Application Scenarios

Oil & Gas Facilities

Used at pipe junctions where fireproofing is critical (API 2218 compliance).

Nuclear Power Plants

Specified for secondary containment piping due to low smoke toxicity.

High-Rise Buildings

Mandatory for vertical service shafts per IBC 2021 Section 721.

For ultra-high fire resistance, ceramic fiber-reinforced phenolic composites are available with 180-minute fire ratings (ASTM E119).

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...