Behind the Scenes: Phenolic Insulation Board - From Raw Material to Final Product

2025-07-31 21:10:57

Why Manufacturing Quality Matters for Phenolic Insulation Board

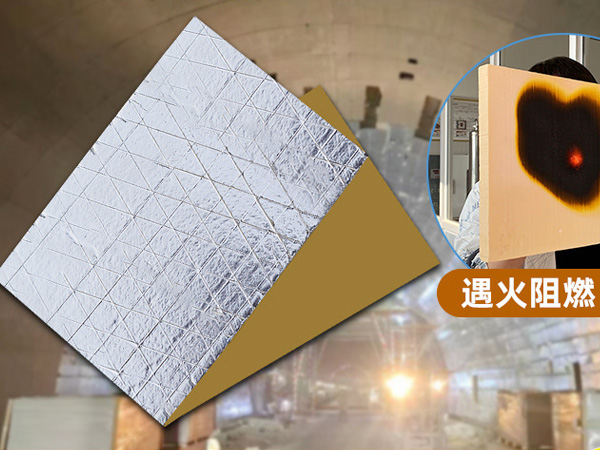

In modern construction, Phenolic Insulation Board is widely regarded as one of the safest and most efficient insulation materials. It is well-known for its exceptional fire resistance, low smoke emission, and high thermal insulation capabilities. But few people understand how these superior characteristics are achieved—not just by design, but through a highly controlled and technical manufacturing process.

This article walks you through how Phenolic Insulation Board is made, from selecting raw materials to producing a finished, high-performance insulation product. Knowing the process helps you appreciate why it stands out in a crowded market of insulation options.

Raw Materials: The Foundation of Performance

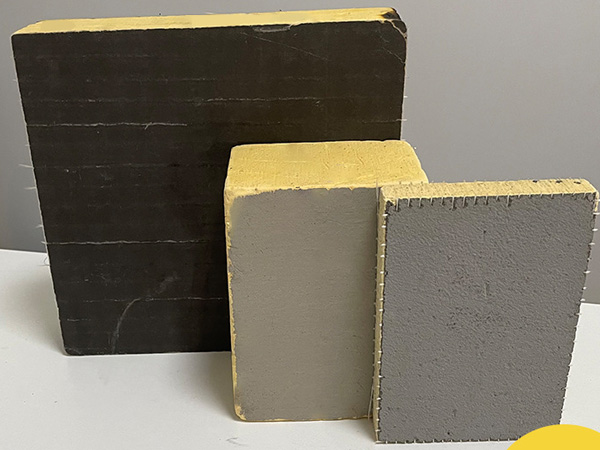

The process begins with the formulation of phenolic resin, which is created by chemically reacting phenol with formaldehyde. This resin is the backbone of Phenolic Insulation Board, offering inherent resistance to fire and heat. High-quality additives are then introduced, such as blowing agents to form the foam structure, catalysts to control the reaction speed, and surfactants to maintain cell stability.

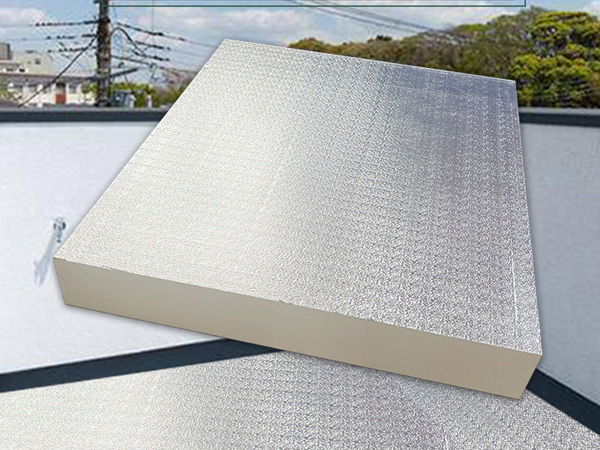

Facing materials are also chosen at this stage. These might include aluminum foil for reflective thermal protection, fiberglass mats for mechanical strength, or even treated paper depending on the final application. Every material is selected to enhance the board’s performance in demanding environments.

Foam Formation: Building the Core Structure

After the raw materials are blended, the reactive mix is introduced into a continuous lamination machine. Here, a chemical reaction causes the mixture to foam, expand, and form a closed-cell structure. This structure is essential for the board’s insulation performance and water resistance.

At the same time, the foam is sandwiched between two facing layers. These layers bond with the foam under precise pressure and temperature conditions. This ensures the final product is not only strong and durable but also dimensionally stable and easy to handle.

Curing: Setting the Structure for Long-Term Durability

Once the foam is formed and laminated, the panel enters a heated curing zone. Curing involves maintaining the panel at a controlled temperature so the resin fully hardens and sets into a stable, thermoset structure.

This step is crucial. It ensures that the Phenolic Insulation Board won’t melt or deform under heat, unlike many thermoplastic foams. Instead, it becomes rigid, flame-resistant, and resistant to shrinkage or warping—making it ideal for both high-rise construction and HVAC applications.

Precision Cutting and Finishing

After curing, the panels are cooled and cut into standard sizes using high-accuracy equipment. Depending on end-use requirements, the edges may be shaped for easier installation, such as tongue-and-groove joints. Surface treatments may also be applied to enhance moisture resistance, hygiene, or reflectivity.

The precision of this step ensures the board fits well within insulation systems, maintaining air-tightness and energy efficiency throughout the building.

Rigorous Testing and Quality Control

Every batch of Phenolic Insulation Board undergoes detailed inspection and testing before leaving the factory. Tests assess thermal conductivity, compressive strength, dimensional stability, water absorption, fire classification, and smoke emission.

What makes Phenolic Insulation Board stand out is its consistent ability to achieve top-level performance across all metrics—something only made possible by tightly controlled production variables. This includes temperature, mixing ratios, foam density, and curing time, all managed through advanced production lines and monitored by automated systems.

Why Phenolic Insulation Board Outperforms Alternatives

Compared to commonly used insulation materials like EPS (expanded polystyrene), XPS (extruded polystyrene), polyurethane foam, or mineral wool, Phenolic Insulation Board delivers a unique combination of high fire resistance, low smoke generation, and extremely low thermal conductivity. These benefits are a direct result of its manufacturing process.

While other products may offer lower upfront costs, they often lack the same safety certifications, thermal efficiency, and durability. Phenolic Insulation Board not only meets but often exceeds stringent international building codes, especially in commercial buildings, hospitals, data centers, and any application where fire safety and energy performance are paramount.

Conclusion: Engineered to Perform from Start to Finish

From the chemical reaction that creates phenolic resin to the final finishing touches on the insulation board, each phase of production is carefully engineered. This attention to detail ensures that Phenolic Insulation Board offers maximum performance where it matters most: fire resistance, thermal efficiency, and long-term durability.

Unlike generic insulation materials, Phenolic Insulation Board is a premium solution manufactured with precision, delivering peace of mind for contractors, engineers, and building owners.

Whether you’re specifying for a high-rise tower or retrofitting a mechanical room, Phenolic Insulation Board is the smart choice. Choose proven performance. Choose advanced manufacturing. Choose the best.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

MLA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...