Why Does Phenolic Insulation Board Last Longer? Here’s the Science

2025-08-04 01:13:50

The Long-Lasting Power of Phenolic Insulation Board

When choosing insulation for a building, lifespan matters. A short-lived insulation product means higher maintenance, more frequent replacements, and increased long-term costs. That’s why Phenolic Insulation Board has become the go-to solution for professionals in construction and architecture—it offers exceptional durability and performance over time.

But what makes it last longer than conventional alternatives like polyurethane, EPS, or mineral wool? In this article, we’ll explore the science behind phenolic insulation’s longevity, its advantages over competing materials, and why its trusted in critical environments from hospitals to high-rises.

What Is Phenolic Insulation Board?

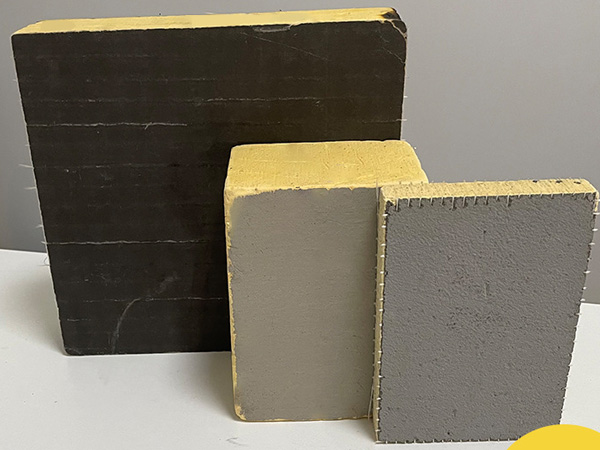

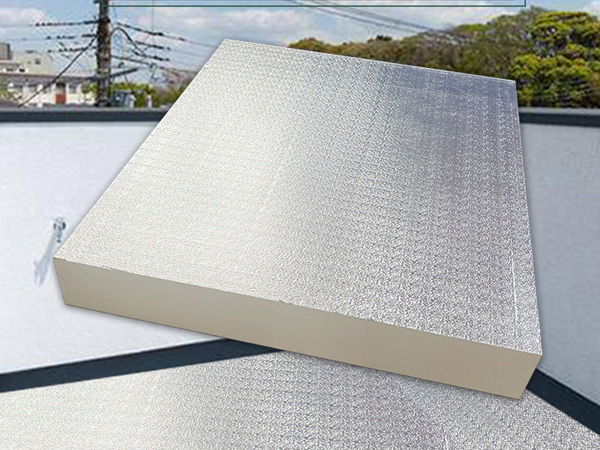

Phenolic Insulation Board is a high-performance rigid foam insulation made by curing phenol-formaldehyde resin with a high-strength blowing agent. The result is a closed-cell structure that provides superior thermal insulation, moisture resistance, and structural stability.

Its durability is a product of both its chemical composition and physical design—both of which are engineered for resilience in harsh environments and demanding construction applications.

Key Reasons Why Phenolic Insulation Board Lasts Longer

1. Exceptional Thermal Stability

Phenolic foam can withstand temperatures up to 120°C (248°F) without significant degradation. Unlike other foams that shrink or warp under heat, phenolic maintains its structure, making it suitable for high-temperature zones like boiler rooms, HVAC systems, and fire-resistant facades.

2. Closed-Cell Structure = Moisture Resistance

Moisture is a leading cause of insulation failure. Phenolic insulation’s closed-cell formation prevents water vapor penetration, which reduces the risk of mold growth, corrosion underneath the insulation, or reduced R-value over time. This waterproofing ability makes it ideal for humid environments, cold storage facilities, and exterior cladding.

3. Superior Fire Resistance

Phenolic boards are Class 0 rated (UK) and meet stringent fire performance standards such as ASTM E84 Class A, EN 13501 Euroclass B-s1,d0, etc. Unlike EPS or polyurethane foam, phenolic does not ignite easily and generates minimal smoke and toxic gases. This reduces long-term risk and ensures building compliance across decades.

4. Chemical Resistance

Phenolic foam resists degradation from most common chemicals and pollutants, including acids, solvents, and hydrocarbons. This makes it perfect for industrial buildings, chemical plants, and coastal installations exposed to corrosive atmospheres.

5. Low Shrinkage Over Time

Thermal insulation materials are often subject to dimensional changes over their lifetime. Phenolic foam has extremely low thermal shrinkage, which ensures it remains snugly fitted in wall cavities or mechanical systems for 20+ years without sagging, cracking, or losing contact with the substrate.

How Long Does Phenolic Insulation Actually Last?

Field tests and real-world applications have shown Phenolic Insulation Board to last 30 to 40 years or more when properly installed and maintained. Some high-quality boards have remained functional well beyond that timeframe in controlled indoor environments.

Its longevity is influenced by:

·Installation quality (correct sealing and fixing)

·Environmental exposure (UV, humidity, chemicals)

·Mechanical stress (movement, vibration, compression)

·Maintenance (inspections, sealing, protection)

When used in accordance with manufacturer recommendations, phenolic foam often outlives polyurethane, PIR, EPS, and mineral wool in similar conditions.

Comparing Phenolic to Other Insulation Materials

Let’s briefly compare phenolic insulation to its main competitors:

·Polyurethane (PUR): Lower cost but degrades faster in fire, and can emit harmful smoke. Less dimensionally stable over time.

·Expanded Polystyrene (EPS): Lightweight and inexpensive, but poor fire resistance and moisture absorption shorten its life.

·Mineral Wool: Fire-resistant and durable, but bulkier and can lose performance if it absorbs moisture.

·PIR Foam: Better than PUR in fire resistance, but still doesn’t match phenolic’s stability or lifespan in harsh environments.

Conclusion? Phenolic foam may have a higher initial price, but it provides unmatched return on investment through reduced maintenance, better safety, and longer functional life.

Certifications That Support Longevity Claims

High-quality phenolic insulation boards come with third-party certifications that guarantee their performance across decades. Look for:

·CE Marking (EN 13166 compliance)

·ASTM and UL fire safety certifications

·ISO 4898 and ISO 5660 durability standards

·GREENGUARD Gold or low-emission ratings

These ensure the board is manufactured to strict international standards and can perform reliably over time.

Real-World Applications That Demand Durability

Because of its long service life, Phenolic Insulation Board is widely used in:

·Commercial and public buildings

·Hospitals and cleanrooms

·Food processing facilities

·Offshore and marine environments

·Transportation infrastructure (e.g., tunnels, subways)

These settings require insulation materials that can stand the test of time while ensuring safety and compliance.

Conclusion: Choose Phenolic Insulation Board for Long-Term Performance

If youre seeking an insulation material that not only performs but lasts, Phenolic Insulation Board should be your first choice. Its durability, fire resistance, thermal stability, and moisture-proof nature ensure it delivers consistent performance for decades.

Compared to traditional materials, phenolic is a premium solution that offers greater value over time, especially in environments where failure is not an option. Whether youre designing a high-rise or a hospital, phenolic insulation ensures peace of mind, cost efficiency, and sustainability—today and tomorrow.

References

GB/T 7714:Bae M, Ahn H, Kang J, et al. Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration[J]. Polymers, 2022, 14(22): 4926.

MLA:Bae, Minjung, et al. "Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration." Polymers 14.22 (2022): 4926.

MLA:Bae, M., Ahn, H., Kang, J., Choi, G., & Choi, H. (2022). Determination of the long-term thermal performance of foam insulation materials through heat and slicing acceleration. Polymers, 14(22), 4926.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...