Thermal Performance of Phenolic Insulation Board in Extreme Climates

2025-09-08 12:15:26

In today’s push for sustainable and energy-efficient buildings, few materials perform as reliably as Phenolic Insulation Board. This advanced insulation solution is engineered to resist both intense heat and severe cold, making it a go-to choice for demanding environments. Whether used in polar housing or desert-based facilities, phenolic boards maintain comfort indoors while reducing energy demand.

This article explores the science behind its thermal properties, its real-world performance in extreme climates, and practical considerations for builders and distributors, including sourcing through bulk supply from trusted China manufacturers.

Why Thermal Resistance Is Critical

Thermal resistance, or the ability to slow down heat transfer, is the defining measure of insulation quality. In extreme climates:

·In freezing conditions, weak insulation means higher heating bills and poor comfort levels.

·In high-temperature regions, insufficient insulation increases air conditioning loads, driving up energy costs.

By maintaining consistently low thermal conductivity, Phenolic Insulation Board ensures indoor spaces remain stable, regardless of outdoor fluctuations.

Unique Properties of Phenolic Insulation Board

1.Exceptional Thermal Efficiency

With conductivity values typically around 0.020–0.025 W/m·K, phenolic boards outperform many other rigid insulations, delivering high energy savings.

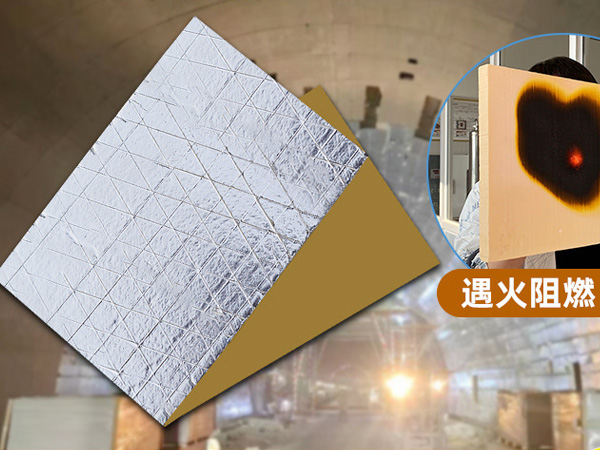

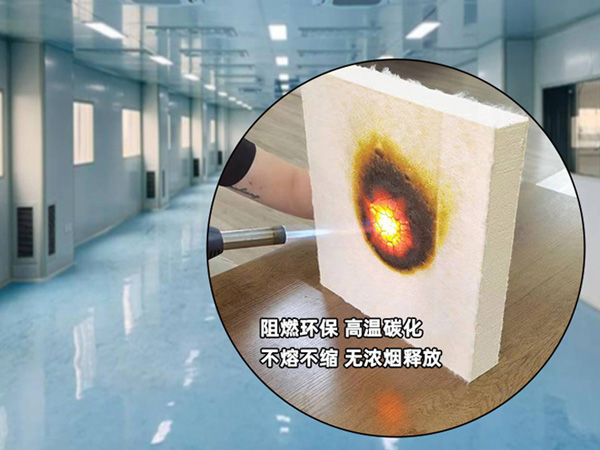

2.Superior Fire Safety

Phenolic foam generates minimal smoke and toxic gases under fire, enhancing building safety compared with many synthetic alternatives.

3.Moisture Protection

Its closed-cell design resists water absorption, preventing mold growth and maintaining insulation over the long term.

4.Dimensional Reliability

Even with rapid temperature changes, phenolic boards keep their form and thermal performance intact, minimizing repair needs.

Performance Under Harsh Climate Conditions

Cold Weather Applications

In icy environments, phenolic insulation retains heat indoors, easing the load on heating systems. Case studies show reductions of up to 40% in heating energy use when phenolic boards replace conventional insulation.

Hot Climate Effectiveness

In desert or tropical climates, phenolic boards act as a strong barrier against external heat, cutting cooling costs. Their resistance to moisture damage makes them highly effective in humid regions where other materials often fail.

Long-Term Stability

Unlike some insulation types that degrade with age, phenolic boards maintain their performance for decades, making them one of the most cost-effective insulation solutions.

Where Phenolic Insulation Board Is Applied

·Wall cladding and façade insulation

·Flat and pitched roofing systems

·Cold storage and refrigeration units

·Industrial piping and HVAC ducts

Its versatility and balance of safety, durability, and efficiency make it indispensable across both residential and commercial construction.

Reliable Sourcing and Bulk Supply

With rising global demand, securing dependable supply lines is essential. Many contractors and distributors prefer China factories that offer bulk phenolic insulation board supply, as they combine competitive pricing with internationally recognized quality standards.

Direct partnerships with such manufacturers not only guarantee availability but also provide flexibility for large-scale projects across diverse climates.

Practical Installation and Care Tips

1.Ensure joints are sealed to prevent thermal bridging.

2.Store and install boards away from standing water to maintain insulation properties.

3.Use reflective layers alongside phenolic boards for improved hot-weather performance.

4.Inspect periodically to confirm insulation remains intact and efficient.

Conclusion: Why Phenolic Insulation Board Stands Out

From frozen winters to scorching summers, Phenolic Insulation Board has proven itself as one of the most resilient and high-performing insulation solutions in the market. Its ability to deliver consistent thermal resistance, fire protection, and long-lasting stability makes it ideal for modern sustainable buildings.

For distributors and project managers, sourcing through China manufacturers with bulk supply capacity provides both reliability and cost-effectiveness. Investing in this insulation material is not just about immediate savings — it’s about ensuring durable, safe, and energy-efficient performance for years to come.

References

GB/T 7714:Tseng C J, Kuo K T. Thermal properties of phenolic foam insulation[J]. Journal of the Chinese Institute of Engineers, 2002, 25(6): 753-758.

MLA:Tseng, Chung‐Jen, and Kuang‐Te Kuo. "Thermal properties of phenolic foam insulation." Journal of the Chinese Institute of Engineers 25.6 (2002): 753-758.

APA:Tseng, C. J., & Kuo, K. T. (2002). Thermal properties of phenolic foam insulation. Journal of the Chinese Institute of Engineers, 25(6), 753-758.

OurFlame Retardant Rubber Foamis a premium closed-cell elastomeric insulation material engi...

OurRubber Pipe Insulationis a high-performance solution designed specifically for HVAC pipi...

Rubber Foam Insulation Sheet – Product Introduction Premium Flexible Insulation for Therm...

Specially engineered for refrigeration applications, ourElastomeric Rubber Insulationprovid...